|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

|

|

1

|

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

9

|

10

|

11

|

12

|

13

|

14

|

15

|

|

16

|

17

|

18

|

19

|

20

|

21

|

22

|

|

23

|

24

|

25

|

26

|

27

|

28

|

29

|

|

30

|

|

|

|

|

|

|

|

|

2 members (Argo44, Jtplumb),

300

guests, and

4

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics38,631

Posts547,172

Members14,430

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Jan 2006

Posts: 9,450 Likes: 329

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,450 Likes: 329 |

John: you may well have 'British Laminated Steel' barrels, and "3 Bell" is likely 3 Iron Laminated. Unfortunately, the Belgians called Twist 'laminated', and c. 1880s US makers labeled One Iron Crolle 'laminated' (usually one grade above Twist and one below 2 Iron Crolle) Check out the pics and descriptions of each on the 'Damascus Barrels' album http://www.picturetrail.com/gallery/view?p=999&gid=16082038You can also access the 'Parker Damascus' and 'Colt and Remington Damascus' by clicking on 'Album List'

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

From Greener, page 228 Best laminated steel barrels are twisted, and the rods welded in the same manner as the stub Damascus, but the rods are composed of superior metal containing a large percentage of steel. Pete

|

|

|

|

|

Joined: Jan 2002

Posts: 631

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 631 |

For a really good read into the background and early trials of fluid steel (and the second and third Reichs), read Manchester's book on Krupp Essen. The German's came late to the fluss stahl party but ended up with the biggest punch barrel; Big Bertha. Herr Krupp was so obsessed with the "secret" of best fluid steel, he disguised himself poorly as an Englishman and sneaked around Sheffield as a 3rd-rate industrial spy. Early on the stuff was so precious, it could only be made in small crucibles and the main use was for stamps and dies. Today, you can tickle a bunch of computers and come up with new car sheetmetal in under 6 months. Amazing what technology can do.

|

|

|

|

|

Joined: Jan 2002

Posts: 527

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 527 |

As I read all the replies and I thank you all for your responses I think there is a little confusion. I believe "3 Bell Steel" barrels are not of fluid steel as some are thinking but steel rods (as PeteM stated). These rods are passed through an annealing process consisting of "in the past" of 3 Bell furnaces, one to heat the material, one to expose the steel to a desired atmosphere and one to cool down the material. I think this is all done within 1 furnace nowadays to produce variuos types and grades of steel. Reading about the process leads me to believe "raw" steel is rather hard and brittle and must be further refined (annealed etc.) to make the desired/required characteristics. Good pic. trail rev I enjoyed the look see-you could call it a damascus and rib trail, I will soon get to work on the barrels, got the action cleaned and the stock is about 90% refinished. The barrel work will be interesting and I will eventually post the outcome (maybe some pics.) --- John Can.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,450 Likes: 329

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,450 Likes: 329 |

John: please get some high resolution ultra-close ups of 'before' and 'after' for the 'Damascus Repair and Restoration' album http://www.picturetrail.com/gallery/view?p=999&gid=17428644You can post them here or e-mail by jpg attachment to revdoc2@cox.net and thanks!

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

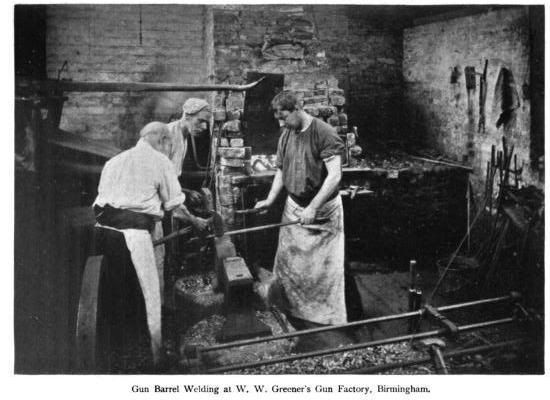

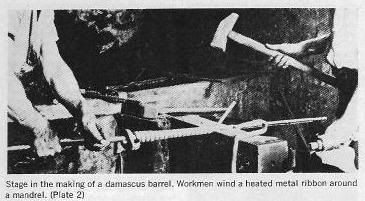

This photo is from Greener's book, in the chapter on laminated steel. While he does discuss damascus in this chapter, nothing in the photo or text refers to it. Looking at it would seem that they are engaged in Damascus fabrication as are the Belgian workers in the next photo, which is from Puraye's article (these same images appear in Gaier's books, so I would assume they are part of a public collection). I believe Greener is showing how English laminated Steel barrels are fabricated. It is my belief, by the way, that this photo may be staged. By 1907 Greener was certainly using auto-hammers for such work. He is "demonstrating the old ways" for his book.   I think the real issue is why bother to produce laminated Steel barrels? Pete

|

|

|

|

|

Joined: Jan 2002

Posts: 527

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 527 |

Pete: IMHO, I think it was a matter of evolution and deduction, why produce damascus barrels in the first place ?-I think the answer would be to combine steel and iron to produce a material that can take the stresses required by a gun barrel. The artistry of the different patterns came later-it was not the initial quest. Once a method was discovered to "anneal" steel making it more pliable and workable and knowing that the steel in damascus gave the barrel its "strenght" the next step seems obvious, an all steel "damascus" barrel. It would seem that the "old Boys" were correct by the proof tests where laminated steel proved to be the strongest. --- John Can.

|

|

|

|

|

Joined: Jan 2002

Posts: 5,954 Likes: 12

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,954 Likes: 12 |

CNF - the "3" with a little square is a proof mark from the sleeving work (sleeved barrels must be reproofed in the UK). It indicates that the barrels were proofed for "3 tons per square inch" of pressure. If the gun is near 1895 originally, then this is reproof as this mark was not in use at that time. 3 ton proof is most usually associated with 2 1/2" chambers and is standard/common for game weight guns. Take the gun out in sunlight and look at both sides of the sleeving joint on the barrels under a magnifier. If the original barrels were damascus, you will most likely be able to see something of the pattern under the blue. Sleeving damascus is an OK way to return a gun with clapped out barrels to shootable, whether the original barrels were steel or damascus. The newer Teague system of lining is better as it preserves the original damascus exterior. The issue between the two is that the Teague system is more expensive and there are many guns that are marginal for this kind of expenditure; many are marginal for sleeving, too.

Last edited by Rocketman; 09/10/07 09:04 AM.

|

|

|

|

|

Joined: Jan 2002

Posts: 5,954 Likes: 12

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,954 Likes: 12 |

The issue with making steel ingots for the barrel trade was to avoid internal flaws from cooling - shrink cracks. Use of steel was clearly a good thing, but not entirely economical until Whitworth produced ingots that were pressed/forged as they cooled sufficient to prevent shrink cracking. The outside of an ingot cools first and sets the dimensions which the inside must "fill out." As the inside cools and shrinks, it will open up cracks and flaws. By compressing the outside and shrinking the external dimensions during cooling, Whitworth gave the inside a smaller volume to keep filled as the ingot cooled.

JC - the steel trade understood that carbon content controlled the hardness of steel. The trade also understood heat hardening, tempering, and annealing of steels with enough carbon to be subject to heat treating. They did not understand how to make thick pieces without flaws pre Whiworth. Measuring and controlling carbon content and temperatures were the big hitters in steel production, along with mechanically shrinking the outside dimensions as the cast ingot cooled.

Annealing does nothing more than make the steel piece as soft as it will get for the alloy involved. It is accomplished by heating the steel above its critical temperature (exact temperature depends on exact alloy) and cooling it slowly. Rapid cooling (quenching) from above critical temperature will make the piece as hard as it will get, depending on the alloy. Tempering is accoplished by reheating the hard steel to the 500 - 700 F range. This trades a little hardness for a lot of toughness; untempered steel tends to be brittle.

|

|

|

|

|

Joined: Jan 2004

Posts: 112

Sidelock

|

Sidelock

Joined: Jan 2004

Posts: 112 |

Another factoid to add. I have an early James Woodward "Automatic" SLNE. It has been sleeved and I had assumed that the original barrels were Damascus. I queried Purdey where the Woodward records reside. They say my gun gun was made in 1880 and orignally had steel barrels. So not only did Purdey and Woodward set the trend for the shape of lock plates they also were early users of steel barrels.

John Vibber

author of "Kingdom Come: A North Country Mystery"

available at amazon.come

|

|

|

|

|