some say never! some say sometimes. some say why not? what say you?

You need to define black powder guns, Ed, do you mean twist barrels?

i would define black powder gun as any gun designed to shoot shells loaded with black powder. that would include those guns fitted with cast, twist, damascus and laminated steel barrels. did i miss any?

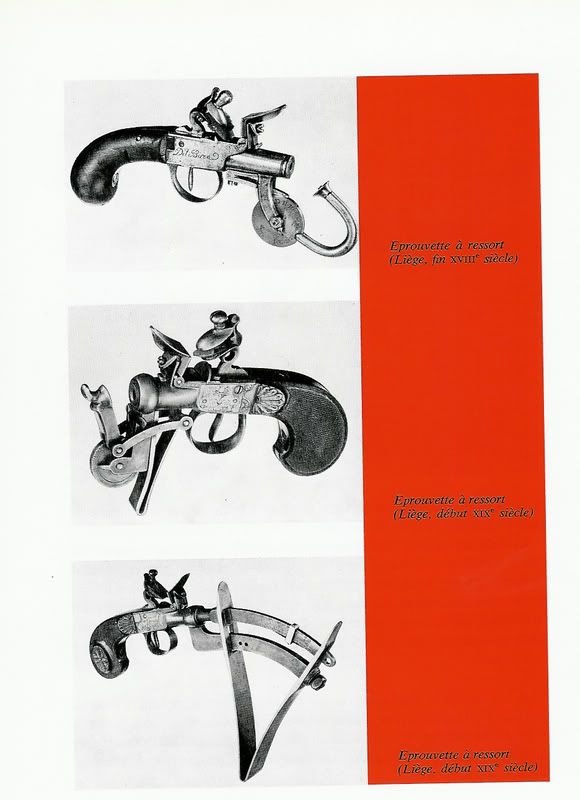

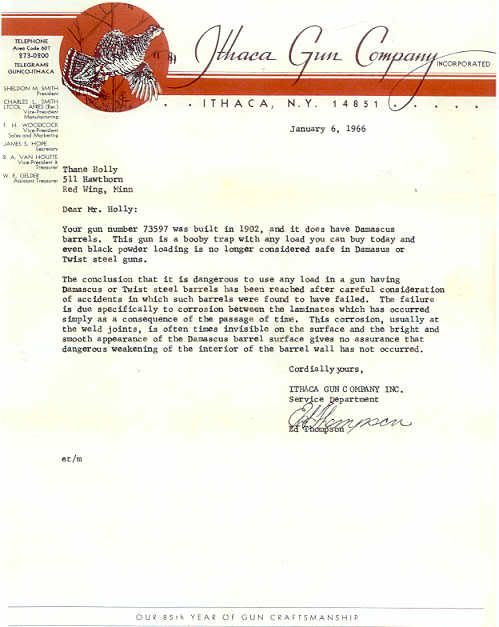

There were far more breech loading double barrel shotguns with Damascus, Laminated and Twist barrels that left Fulton, Syracuse, Ilion, Meriden, Batavia, and Ithaca, that were at the time guaranteed for nitro powders than were ever said to be for black powder only.

Here is the kind of breech loader shotgun that was for black powder only --

If one sticks with appropriate pressures, and especially since Bell pretty much destroyed the theory that BP has a significantly different pressure curve than smokeless, I don't see why not. If it's safe with one, it should be equally safe with an equivalent load of the other.

We are all fortunate indeed that the makers of a century+ ago didn't have to wait on Bell. As smokeless powders came into general use they simply insured their guns had adequate thickness in the "Breeches" & guaranteed them for smokeless. I truly wonder where they found this out.

By the early 1920's of course E I DuPont De Nemoures Had those pressure curves well drawn out, but the Gunmakers practise of wall thickness proportions had by then long since been established.

"All Bored For Nitro Powder" c. 1895

I shoot moderate pressure loads ( 5500-7500 psi) in all of my

"Black Powder Guns" as well as all of my associates. The only burst bbls have been in three steel bbls guns that I have seen.

It is an "overblown" myth and worry.

Read Sherman Bells DGJ articles with proof loads in some of the old damascus guns if you are nervous.

In 12 ga black powder damascus I regularly shoot 5000 psi 1oz loads. One can probably go higher than that depending on the gun, but I drew the line there and so far (knock on wood) there have been no issues. Look at SR7625 loads in Federal Gold Metal Hulls and you should be ok.

I use RST and Polywad cartridges in my composite barreled guns. I just tried a box of RST short tens in my 'New Baker' hammer gun with 'one iron crolle' barrels. Until I start loading for my short 10s, I have no problem with the aforementioned ammunition. Cheers!

What the Chief said! I loaded LP loads for my Damascus & Twist guns for a while, then as my volume of shooting tapered off I shoot what Guns shoots..

What happened, after the advent of "modern" smokeless loads in the 20's, was that ammo makers started putting two warnings on their shotshell boxes: Don't shoot in guns with Damascus/twist barrels, and don't shoot in guns with chambers shorter than 2 3/4" (assuming that was the length of the shell in question). Those warnings made sense, not because Damascus was unsafe with smokeless nor because the extra 1/4" hull length was a problem in and of itself, but because those modern shells could develop higher pressures than those which Damascus/short chambered guns had been built to withstand.

Eventually, those warnings were (incorrectly) translated to mean that no smokeless loads are safe in Damascus guns, nor are any 2 3/4" loads safe in guns with 2 1/2" chambers.

My Father, Grandfather and Uncles were all convinced that those Damascus and Twist barrel warnings were just an attempt by the manufacturers to scare consumers into buying a new gun. I know my Father's 1896-vintage AE-Grade Remington Hammerless Double and my Grandfather's 1890-vintage PH-Grade Parker Bros. double both digested many, many, cases of Super-X and Federal Hi-Power shells over their lifetimes. Dad's AE-Grade is still looking fine in my gunroom. He shot it up to when he quit hunting in 1988 after he turned 81.

For two or three decades now I've heard this moaning over modern "SAAMI" spec ammunition. But, I've never seen any definitive information on what the pressure specs were for earlier nitro powder loads like say 3 1/4 drams of DuPont (or Schultze, or E.C., or Hazard, etc.) bulk smokeless powder and 1 1/4 ounce of shot, or say 26 grains of Infallible (or Ballistite, etc.) dense smokeless powder and 1 1/4 ounces of shot??? I have an early Western Cartridge Co. brochure on their Super-X load, and it says with their new progressive burning powder they are achieving this level of performance at lower pressures. But, I think that means a 3 3/4 dram equiv. load and 1 1/4 ounce of shot, while with the older bulk smokeless powders the heaviest 12-gauge loads offered were 3 1/2 dram.

Have been loading and shooting low pressure smokeless as a substitute for black, for about 35 years. All digits and optics and other extremities still intact. No evidence of pressure issues with

any damascus guns. Only problem is that now that the "dangerous damascus myth" has been debunked, it is no longer possible to buy all those best quality "unsafe" British guns at bargain prices anymore. Great ride while it lasted.... As Larry says, many thanks to the ammunition makers who managed to convince a couple generations of shooters to condemn damascus guns. Worked for me...

"All Bored For Nitro Powder" c. 1895

Any guess on the date of this advertisement? I have an 1897 vintage elsie hammerless I am working on right now, I am thinking it was made after this advert?

Are the Winchester featherlight shells light enough to be included in the same class with the RST and Polywad loadings?

Thanks,

CHAZ

My Father, Grandfather and Uncles were all convinced that those Damascus and Twist barrel warnings were just an attempt by the manufacturers to scare consumers into buying a new gun. I know my Father's 1896-vintage AE-Grade Remington Hammerless Double and my Grandfather's 1890-vintage PH-Grade Parker Bros. double both digested many, many, cases of Super-X and Federal Hi-Power shells over their lifetimes. Dad's AE-Grade is still looking fine in my gunroom. He shot it up to when he quit hunting in 1988 after he turned 81.

For two or three decades now I've heard this moaning over modern "SAAMI" spec ammunition. But, I've never seen any definitive information on what the pressure specs were for earlier nitro powder loads like say 3 1/4 drams of DuPont (or Schultze, or E.C., or Hazard, etc.) bulk smokeless powder and 1 1/4 ounce of shot, or say 26 grains of Infallible (or Ballistite, etc.) dense smokeless powder and 1 1/4 ounces of shot??? I have an early Western Cartridge Co. brochure on their Super-X load, and it says with their new progressive burning powder they are achieving this level of performance at lower pressures. But, I think that means a 3 3/4 dram equiv. load and 1 1/4 ounce of shot, while with the older bulk smokeless powders the heaviest 12-gauge loads offered were 3 1/2 dram.

Researcher, can't help you with the pressure specs on those "pre-modern" smokeless loads. However, I did save a discussion of proof and service pressures on old, short chambered guns--courtesy of Greg Tag, going back quite a few years. Greg quotes Calvin Goddard in the May-June issue of "Army Ordnance", as reporting that Hunter Arms proofed its short 12ga guns at 14,300 psi. Parker's short 12's had a service pressure of 9500 psi, and both Parker and Ithaca proofed at about 15,000 psi. Given the date of that article, I think the psi figures are more likely to be LUP, since crushers were still being used back then. So, using the "ballpark" psi to LUP conversion of +1,000, we get a service pressure of around 10,500 psi for those guns. That figure is further substantiated by Arthur Curtis in a 2-part article in the American Rifleman, also in the 30's, addressing the issue of long shells in short chambers. Curtis, who had worked in the firearms industry for about 40 years and was with Marlin at the time he wrote the article, suggested that the "modern" loads increased pressure by about 1,000 psi. That fits quite nicely, because it would mean they were at the current SAAMI 12ga service pressure standard of 11,500 psi.

Like your father and grandfather, back in the "day"--although my day isn't as long ago as theirs--I shot numerous high brass 1 1/8 oz pheasant loads through a pre-war Sauer and an Ithaca Flues, both 16's and both of which had had the chambers lengthened. Can't say that it did anything bad to either of those guns, although I would tend to err on the side of caution today, knowing what I now know (much of which I've learned here).

"Greg quotes Calvin Goddard in the May-June issue of "Army Ordnance", as reporting that Hunter Arms proofed its short 12ga guns at 14,300 psi"

Larry, Hunter Arms never had a "short" 12 ga., all 12ga. guns from the begining were 2 3/4" chambers.

I guess about as close as we have to the early pressures are those mentioned from the early 20's. These were recorded for a 3DE load with 1Ľoz shot. As noted older loads used up to 3˝DE of powder with the 1Ľoz of shot. The 3 dram measure of DuPont Bulk load certainly did not fall into what we refer to today as "Low Pressure"

In an srticle on Shotgun powders in the american Rifleman back sometime in the 1950's they stated that Infallible was the same powder as Unique. 26 gtains of Unique with 1Ľoz shot is not a particular low pressure load even in paper cases with card & filler wads & can only really assume that neither was the same load using Infallible.

Another point is that when some of the old makers stated "Bored For Smokeless" this often refered to the size of the hole down the bbls. Many of the older gunes were "Bored" for the use of the all brass shelles with black powder & thus had oversize bores. Re-loading with smokeless was generally discouraged at that point of time. Thus a person who intended using smokeless was expected to be buying factory loads put up in paper cases with standard wadding so the barrels were bored nearer to standard gauge size.

I personally still prefer for my sound damascus guns to shoot relatively fast powders with loads in the 7-8K psi range than to court disaster with those Super-Low pressures in the 5K range acheived by underloading the slow powders. In my Lefevers by comparsion to the loads listed in their catalogs even the 8k loads are quite mild.

Miller, I don't know much about the other gun manufactures, and if some of them back then were overboring for black powder, I can only go from bore readings I have taken on L.C. Smiths from 1884-present. What I have found is that most were ,725-.730, and most of the early hammer from Hunter Arms were .725.

My Skeet's gage only reads to 12 1/2" and from the breech most were bored so, funny thing is going from muzzle down 12 1/2", past choke area, most read .720 and some slightly lower. This is true for both hammer and hammerless. I'm wondering if this is what L.C. Smith Maker and Hunter Arms referred to as "Multiplied Choke Boring" for better patterns.

I had read somewhere that 12 ga. bores were .729 -.002 +.000. I couldn't find it in both of Brophy's books, but I'm sure it is in there. I know that in his "L.C. Smith Shotguns" he lists on one page the bores, and the 12 ga. as now being .732. Also listed is the 16 ga. as .662, so this had to be in the 1930's when the change was from .650 to .662.

I was taught that if it was a three decimal reading the tolerances were +/- .005 unless noted. I do see in some, the tolerances were + .000 -.002.

How well their quality control was, who knows.

some say never! some say sometimes. some say why not? what say you?

Why do you ask Two Dogs ...?

sounds like barrel wall thickness is a decision making factor here. so, what are minimum barrel wall thicknesses recommended for the various barrel materials? and how much of an issue is bore pitting?

"Greg quotes Calvin Goddard in the May-June issue of "Army Ordnance", as reporting that Hunter Arms proofed its short 12ga guns at 14,300 psi"

Larry, Hunter Arms never had a "short" 12 ga., all 12ga. guns from the begining were 2 3/4" chambers.

My bad, JDW. Good catch. The Hunter proof figure I reported was correct (14,300 psi), but that was for the 2 3/4" 12ga. The 2 5/8" service pressure figure of 9500 psi was the then-current SAAMI standard, which was what Parker used for its short-chambered 12's.

My Father, Grandfather and Uncles were all convinced that those Damascus and Twist barrel warnings were just an attempt by the manufacturers to scare consumers into buying a new gun. I know my Father's 1896-vintage AE-Grade Remington Hammerless Double and my Grandfather's 1890-vintage PH-Grade Parker Bros. double both digested many, many, cases of Super-X and Federal Hi-Power shells over their lifetimes. Dad's AE-Grade is still looking fine in my gunroom. He shot it up to when he quit hunting in 1988 after he turned 81.

You come from a very smart family. A manufacturer has to sell the latest product to stay in business.

45 years later and we are still shooting damascus.

45 years later and we are still shooting damascus.For two or three decades now I've heard this moaning over modern "SAAMI" spec ammunition. But, I've never seen any definitive information on what the pressure specs were for earlier nitro powder loads like say 3 1/4 drams of DuPont (or Schultze, or E.C., or Hazard, etc.) bulk smokeless powder and 1 1/4 ounce of shot, or say 26 grains of Infallible (or Ballistite, etc.) dense smokeless powder and 1 1/4 ounces of shot??? I have an early Western Cartridge Co. brochure on their Super-X load, and it says with their new progressive burning powder they are achieving this level of performance at lower pressures. But, I think that means a 3 3/4 dram equiv. load and 1 1/4 ounce of shot, while with the older bulk smokeless powders the heaviest 12-gauge loads offered were 3 1/2 dram.

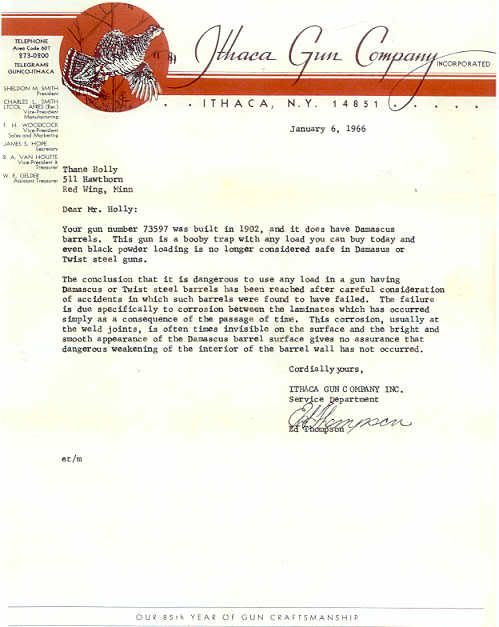

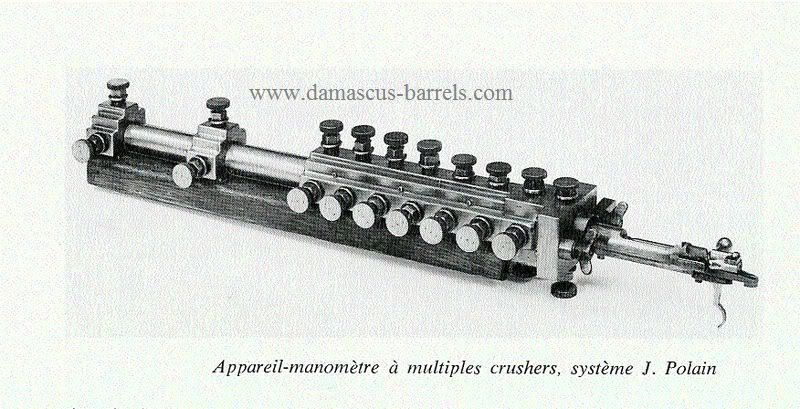

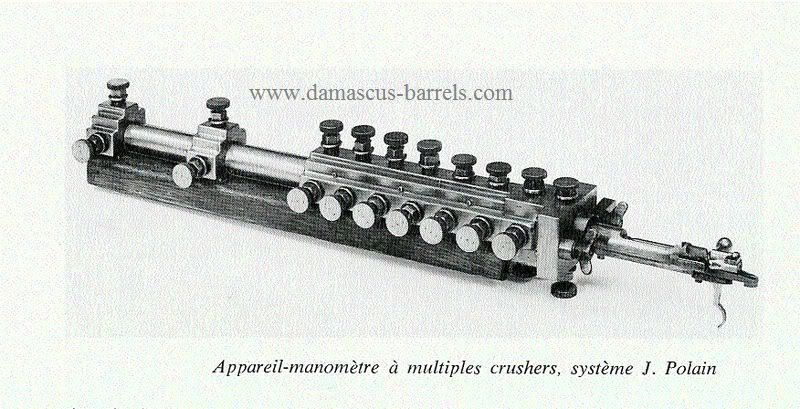

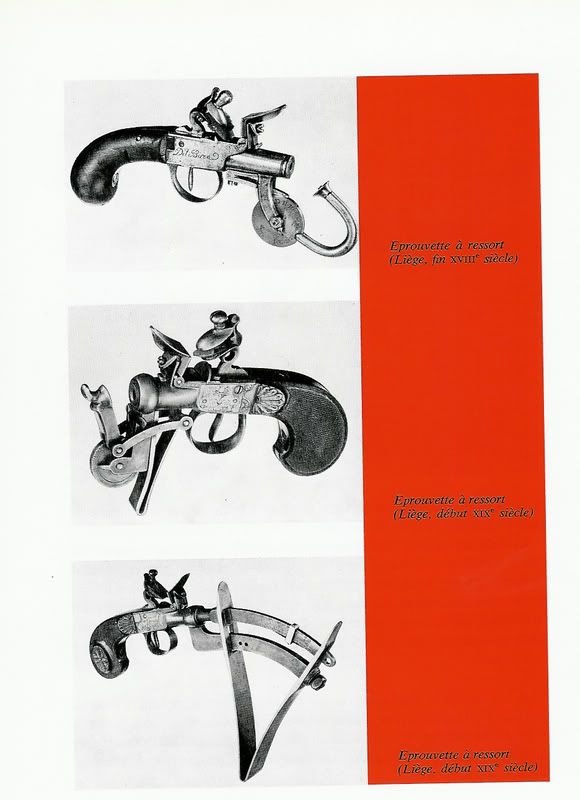

The ability measure a load by "lead crusher" was around from the 1890's. The powder makers had a tough time keeping the pressures the same from batch to batch. So the proof houses had their own tools to accomplish this.

Pete

re: the ithaca letter...i have also heard that it is dangerous to shoot english made guns made prior to ww1. seems like they used an acid flux to flow the solder used to join barrels. the theory is that the acid slowly eats the steel and leaves the barrel walls very thin behind the solder joints. logically, it makes sense...supposedly, only the english used an acid flux. seems like everyone else knew better. now, that really doesn't make any sense...

In early Lefever Arms Co catalogs it was recommended for black powder use to load wads two sizes larger than the gauge. As best as I can determone this was speaking of actual wad diameter. By the time i started reloading just prior to the plastic age a card wad in a box marked 12 gauge actually measured to about an 11 ga. While those marked 11 for use in the brass shells measured to 10ga dia's. This would have been the wads efever referred to as "Two" sizes larger than the bore gauge. Many 12ga Lefevers of that era do have bores which run large in the 11 ga area. These same catalogs advised if getting the gun for smokeless to order it "bored" for standard wads only one size larger than gauge.

I can only conclude the term "Bored for Smokeless" has reference to the bore diameter & not the wall thickness. I think by this time regardless of the "Bore" most US makers were using suitable wall thickness over the chambers to handle the smokeless loads of the era. You won't find many guns from the 1890's or later having very light breeches to their bbls.

i have several damascus and twist barreled guns, ive used IMR7625 in all of these guns, no issues at all, great performance, i have 2 grade A remington model 94"s both 2 stripe damascus, also a lefever heavy damascus sidelock 12 gauge with 3 strip damascus , and a small english sxs hammer gun, twist barreled, im loading in federal hulls 25.5gr of 7625, WIN AA12 wad, 1 1/8oz loads, with WIN 209 primers, load is about 7000psi, works fine, i use winchester target hulls also with 23.5gr same components, only diff is the hull, pressure runs at about 6300 psi, both loads work fine, i use#6, #4 , also heavier shot sizes, BB doesnt offer a high pellet count but it patterns well

hope it helps,

The other issue to remember, when evaluating vintage pressure data, is that you get different psi readings, crusher method vs electronic transducer. Once we went to the transducers, reloading manuals corrected for the difference by referring to psi taken using lead crushers as LUP--or lead units of pressure. So, when you read vintage literature concerning pressure--certainly anything written before WWII--when you see psi, it actually means LUP. Thus, the psi figures I gave, above--for Hunter Arms guns and for the then-current SAAMI standard for short-chambered guns--are actually LUP. Which means, ballpark, you'd have to add about 1,000 to get the current psi equivalent.

I shoot six Remingtons, five Parkers, and an English SxS, all damascus. The Brits still proff damascus guns today, so I don't believe for a momount the acid flux crap. Over the years I've used PB, 700X, 800X, Red Dot, Solo 1000, Nitro 100, Promo, and Clay Dot for low pressure shells [ anything around 7000psi or under ]. Only problem was when I thought I was loading Pyrodex and used 94grs of PB - according to Tom they were 24,000psi. Not good. But that was 5 or 6 years ago and now I have one s. stage press for smoke. My early 12ga Parker hammerguns have bores at .745, which was pretty much the standard back then. The Parker 10 hammergun is at .800. But they all have such heavy breechs I don't worry. Paul