|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

1

|

2

|

3

|

4

|

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|

12

|

13

|

14

|

15

|

16

|

17

|

18

|

|

19

|

20

|

21

|

22

|

23

|

24

|

25

|

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

|

2 members (Jeremy Pearce, SKB),

226

guests, and

7

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics38,537

Posts546,033

Members14,420

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Nov 2005

Posts: 1,274 Likes: 1

Sidelock

|

OP

Sidelock

Joined: Nov 2005

Posts: 1,274 Likes: 1 |

While in the process of building a benchtop barrel thickness gauge it dawned on me that this idea could be used for measuring chambers with some changes. Here is something I quickly threw together, it is easy to see when the forcing cones are reached, no guess work. Laying the barrels on a flat surface and sliding the tool into the chamber is simple. No need to have a real rigid probe as you are just looking for the change of thickness, what do you guys think?? Yes I know the 3” mark is in the wrong place. Jim A.

I learn something every day, and a lot of times it's that what I learned the day before was wrong

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

Looks like it should work

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Agree with Joe.

As you go down the chamber you should be getting a gradual thinning of the wall, then as the cone is contacted there would normlly be a quick reversal as the wall gets thicker upon entering the cone. A careful study of this will also reveal why lengthening a chamber results in a thinner wall, but the cone can be lengthened considerably without a resultant thinning.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

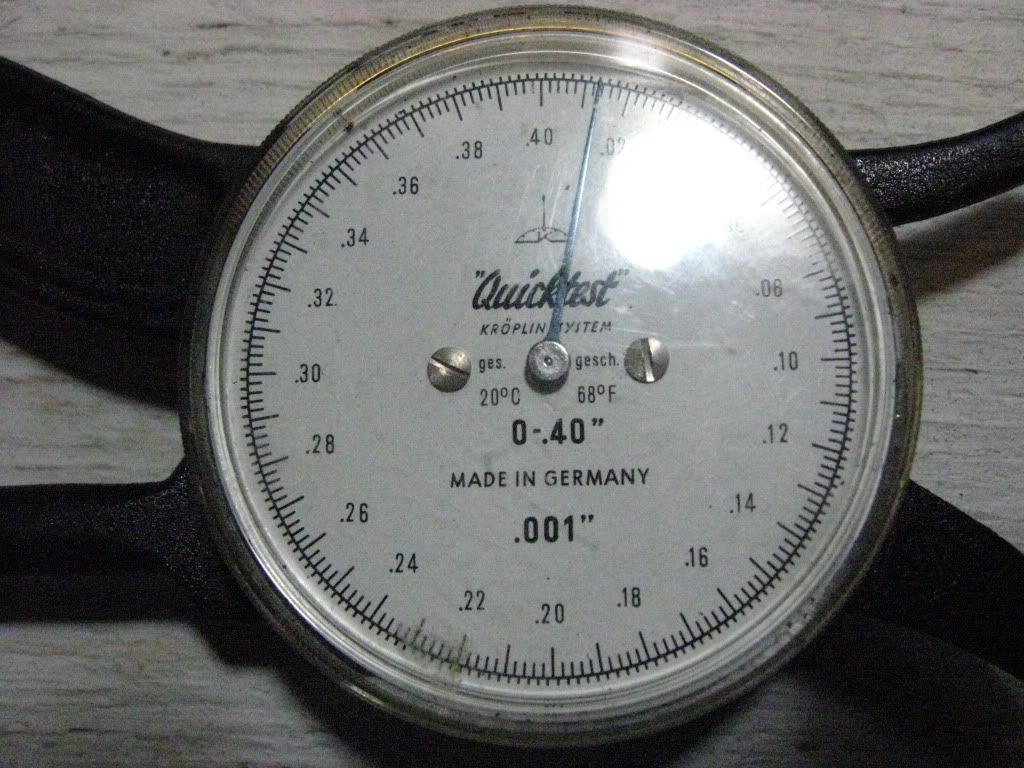

The best gadget I've ever saw to measure a chamber was a tool that Ken Owens had....I don't know the technical name for it but it was a dial indicator with two levers on it that were about 3 inches long.

|

|

|

|

|

Joined: Apr 2002

Posts: 6,812

Sidelock

|

Sidelock

Joined: Apr 2002

Posts: 6,812 |

No reason that quick blips of the indy needle in combination with the depth scale won't give you some indication of cone beginning and ramp. Also no real difference from a wall thickness guage other than shorter internal and external legs. I've done this with a w/t gauge but with the scale on the internal rod to see if there's a quick reverse of needle movement at a certain graduation--say 2.75". And thanks for the help on the Parker Trojan, Jim. Worked out fine; stoning both sear nose and hammer notch on the right got right hammer cocking earlier. Have now checked for jaroff loading two, shooting one barrel then the other, loading two, shooting the other then the one. Fixed for now; didn't attempt to reharden anything. See what happens.

jack

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Joe;

I don't really recall now just what the "Catalog" name of the idicators you described was. In the Machine shop we referred to them as "Frog Legs". As you say they are about the best it gets for measuring chamber depth.

The cheapest you can go & get adequate reliability is a 6" flexible scale. Just hold the bbl up to put the cone in a shadow & measure to the shadow by eye. With a little practise one can quite easily read it to within the 1/64" markings of the scale.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Nov 2005

Posts: 1,274 Likes: 1

Sidelock

|

OP

Sidelock

Joined: Nov 2005

Posts: 1,274 Likes: 1 |

I believe this is the gauge Joe was describing, I have 1 that I've used for years and it works well the only problem is that both legs are inside the bore and the depth is difficult to read. Also new is about 100.00.  Using a wall thickness gauge works except for the size of the thing, a bore gauge will work also, again not really portable. I have a set of chamber gauges, but its guess work on the taper of the chamber on each gun. This gauge is cheap to make a 10.00 dial gauge from Harbor Freight, a 1x4x6 piece of wood and the probe. it can be a 3/8 wood dowel. I have tried it on several barrels, you can see precisely where the forcing cone starts and it is portable. Making it a little longer, the forcing cone length could be measured. Jim A

Last edited by james-l; 09/06/10 02:58 PM.

I learn something every day, and a lot of times it's that what I learned the day before was wrong

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

You know where you can buy a gauge with the legs on it ?

|

|

|

|

|

Joined: Nov 2005

Posts: 1,274 Likes: 1

Sidelock

|

OP

Sidelock

Joined: Nov 2005

Posts: 1,274 Likes: 1 |

Joe, McMaster-Carr has them in their catalog, 115.00; also a couple on Ebay, search for inside dial caliper, 40.00 to 50.00 current bid.

Jim A.

Last edited by james-l; 09/06/10 03:23 PM.

I learn something every day, and a lot of times it's that what I learned the day before was wrong

|

|

|

|

|

Joined: May 2010

Posts: 1,530 Likes: 82

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,530 Likes: 82 |

Sorry but if you want to measure chamber depths stick to a graduated plug gauge. As a wise American once said "If it aint broke dont fix it."

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

I picked this up on Ebay some years ago. Didn't pay much as I recall. It will easily measure to a depth of 6 inches. Pete

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

A Graduated Chamber Gauge is Absolutely & Totally Dependant on an exact match of diameters with chamber end. Their use was promoted & advertised by sellers of Chamber Reamers, or Gunsmiths doing chamber jobs. Many, Many a chamber has been reamed & tampered with because it just happened to be a thou or two under-size which was totally immaterial, but they brought a few entrepreneurs a bundle of Cash. Having checked a few chambers short which were not I discontinued use of a "Chamber Gauge" & depend on my Starrett 6" scale, measuring to the shadow line. A $3.00 General scale from your home improvement store will do the same job just as well, I just happen to still have my Starrett. "IF" the gauge is not an exact match to the chamber diameter the scale is the more accurate.

Those internal dial calipers as pictured are very good, but expensive unless one has a lot of use for them. I don't need one that often. Such items were company furnished at work so I didn't have one in my personally owned toolbox.

PS; Many of those chambers I mentioned were "Fixed" because of a chamber gauge, "BUT" they "Weren't Broke".

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: May 2010

Posts: 1,530 Likes: 82

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,530 Likes: 82 |

My plug gauge is made to CIP measurments .If you are talking con men ,any gauge can be used to pull the wool, the more complex the better to fool.

|

|

|

|

|

Joined: Feb 2006

Posts: 3,737 Likes: 55

Sidelock

|

Sidelock

Joined: Feb 2006

Posts: 3,737 Likes: 55 |

My main interest is L.C. Smiths. In Brophy's book "Plans and Specifications" there are factory drawings of chamber lengths and the taper used. Gives the starting bore size and the ending bore size. For a 12 ga. the chamber length from the begining was 2 3/4" or in some 3" if stamped. Start was .811 and 2.750 later waas .797. Forcing cone taper on all gauges was .014 in 2 3/4". I'm sure other makers had similar drawings. I've made these plugs in aluminim and they fit right to the 2 3/4" mark in most guns. The guns they don't fit in were probably polished.

Last edited by JDW; 09/07/10 04:49 PM.

David

|

|

|

|

|

Joined: Dec 2001

Posts: 775

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 775 |

For any plug gauge to work to tell us chamber length, both the chamber and the gauge have to be machined to standards. It is pretty easy to machine the plug gauge to standard with no tolerances, but much harder to ream the chamber to standard each and every time. Reamers wear and have to be sharpened periodically, and the number of times they are/were sharpened might depend on the financial condition of the company, but in any case they would be used sometimes after they no longer met the standards of the time. The taper of the chamber is 0.005" per inch of length. If the reamer has been sharpened until it is 0.002" undersize, a properly sized chamber gauge will indicate that the chamber is o.4" shorter than it actually is. I have two Tobin doubles that illustrate this. Both show a 2.5" chamber when checked with plug gauge, but when checked by another means show that the forcing cones actually begin at 2.75". I have used several means to check chamber length, and usually use the plug gauges first because they are the handiest, but if I suspect some anomaly, I will use another method to verify the gauge. The way I usually check is with a pair of spring loaded round leg inside calipers. When set with a light friction fit in the rear of the chamber and slid to the front, a slight increase in friction is felt until they come to the forcing cone, at which time an abrupt change will be felt. I mark the legs of the caliper and measure with a rule after I withdraw them. I could mark the legs of the calipers with a light nick from a triangular file, and would need no other tool for measuring chambers of any gauge, and all for about $10.

|

|

|

|

|

Joined: Nov 2006

Posts: 3,437 Likes: 34

Sidelock

|

Sidelock

Joined: Nov 2006

Posts: 3,437 Likes: 34 |

You know where you can buy a gauge with the legs on it ? You can pay hundreds for a Starrett or Mitutoyo, but Enco has Chinese knockoffs for a whole lot less money. Accurate enough to take to gun shows or stores to measure guns you are considering. With a 3-1/4" reach, also useful for measuring choke constrictions and tapers. Enco also has a house brand (also Chinese) that is much better quality than their low-end unit, and this one is good enough for the work bench, but I don't remember the brand name.

|

|

|

|

|

Joined: Jan 2010

Posts: 683

Sidelock

|

Sidelock

Joined: Jan 2010

Posts: 683 |

Would a chamber cast using Cero-Safe work? Cheaper than $100.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

I'm talking about gages made to specs. Problem here is so many of the guns we deal with here were made prior to those specs. With a body taper of .005" per inch a mere .001" too small chamber will stop a gage short by .200" or a 2 3/4" chamber will show up as approximately 2 9/16. That .797 JDW mentioned in the L C Smith specs is neither SAAMI nor CIP specs, but simply SS (Smith Specs). I made a very nice set of gages 12, 16 & 20 to SAAMI spec for minimum chamber dia at forward end. I very quickly found that dealing with pre WWI guns I could get a much more accurate measurement of actual chamber length with my 6" scale than with these precision turned gages. This is a case where one size just won't fit all.

"IF" one wants to get arrogant as to the ""ONLY"" way to do it then what ois really needed is some cerro-safe casting alloy & a shadow-graph to read the cast. With this set up you can find absolutely anythibg about the chamber, bore, cone etc you would ever want to know.

My friend I spent 35 years in a machine shop measuring everything imaginable & I can assure you a set of those gages is not the "Only" way to accurarely measure chamber depths, in fact they are not even the "Best" way, "Unless" you individually build a gage to fit for each & every chamber needed to be measured. But by the time you figure that out you have no further need for the gage.

But Hey, if you want to rechamber your guns from 2 3/4" to 2 3/4" just because one happens to be .001-.002" under the gage size that's fine with me. As to my guns "IF THEY AIN'T Broke I DON'T FIXEM" so I'll just keep right on using my little $3.00 scale.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: May 2010

Posts: 1,530 Likes: 82

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,530 Likes: 82 |

The British Proof houses use plug gauges. That's good enough for me. As to those who wish to use other methods, then that's down to them .

As to those who question the accuracy due to variation in cutter size or due to wear ,that's why there are tolerances with maximum and minimum's both in diameter and depth.

Shot gun cartridges are not accuratly sized like metalic ammunition so the tolerances are much greater.From memory a 12bore chamber has .010"in diameter and about .100" in depth.

|

|

|

|

|

Joined: Feb 2006

Posts: 3,737 Likes: 55

Sidelock

|

Sidelock

Joined: Feb 2006

Posts: 3,737 Likes: 55 |

gunman, I agree to what you said. If the reamer did have wear, then the when it came to the inspection team to look at them, it would get sent back.

Most L.C. Smith drawings are three places past the decimal and back when I worked in fairly close tolorence work, three places fast the decimal meant I believe +/- .005, two past decimal was +/- .025. Most of our drawings were stated how much in plus or minus, and some were plus .002, minus .000. Also I believe four places was +/- .0005.

All of our machines were in metric, and usually were one to one on the lathes, which made it easier than in thousandths, but decimals in thousandths was in parenthases

Last edited by JDW; 09/09/10 07:27 AM.

David

|

|

|

|

|

Joined: May 2010

Posts: 1,530 Likes: 82

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,530 Likes: 82 |

Now we are getting technical when most of the guns talked of on these pages were made the English Trade worked in "attals" this is an obscure measurment system adopted by many trades and relied on the skill of the crafts man involved.A mixtue of basic measuring equipment and a "feel" for what was right. This was in the days before common use of micrometers and other high tech equipment.

The "attal"in fact was thus .That'al be right and That'al be good enough.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Thank You Gunman;

This "Attal" post effectively describes the conditions prior to adoption of SAAMI & CIP Specs & is the precise reason a single plug gage per Gauge size cannot be depended on to give an accurate measurement of chamber depth in all cases. In fact most of those guns in which it would be accurate will have chamber length marked anyway.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: May 2010

Posts: 1,530 Likes: 82

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,530 Likes: 82 |

How accurate do you want to be ? How accurate do you need to be?

Provided the chamber is within the proscribed tolerances for purposes of proof, if that should apply,or unless you have a problem with ejection or exessive recoil etc., then yes you can use one plug to measure with. To be honest here folks I think there is a problm being created out of nothing. The original post suggested an a alternate way to measure chambers. The question I now pose is "how accurate are case lengths and diameters"?And does it realy matter providing the over all perameters are correct and within acceptable tolerances.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Sorry but if you want to measure chamber depths stick to a graduated plug gauge. As a wise American once said "If it aint broke dont fix it." ""To be honest here folks I think there is a problm being created out of nothing."" Well now to be "Honest" Gunman, a discussion was being made in which various methods were being discussed of performing this job. All could, & have been, shown to give satisfactory accuracy, some as cheaply as $3.00 (My Scale) & some going to over $100.00 Those +$100.00 tolls are great tools if one has enough need for them. You, Gunman (read Your Quote) were the one to come in & insinuate "ONLY" your way was good enough. It has I believe in fact been adequately documented, with reasons explained, that of all the methods mentioned "Your" method is the only one discussed that under certain conditions can be So Far off as to be totlly Useless. It is a great method if gage & chamber are properly matched, BUT remember we are dealing with guns which may go over 100 years old, form a half dozen or so country's & from a myriad of makers. They Ain't All got the Same diameter chambers. So I ask you the same question you asked "How Good is Good enough". Well I have stated I can read a chamber depth with my little 6" scale to within ± 1/64". It has been explained how if that chamber just so happens to be .001"-.002" undersize your plug will read it .200"-.400" short. My answer to this question is ± 1/64" on chamber depth is quite sufficient for my purposes -.200" to -.400" is not. What's your take?? Certainly I have not espoused that it is a necessity to measure shotgun chamber lengths to within ±.001" or some other ridiculous tolerance. My discontinuance of using the plug gages was brought on entirely by the experience of actually using them & finding for myself their shortcomings. I am just trying to pass those findings on to others who may want to reconsider investing the time or money in obtaining a set.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: May 2010

Posts: 1,530 Likes: 82

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,530 Likes: 82 |

Piper, I never said my way was the only way ,I stated that in my opinion it is still the best way. It may not be perfect in every case and some time you come across old guns with "tight "chambers that will not take a plug.But talking in general, based on over 40years of building and rebuilding double guns,I felt my comments may have some value to the debate.Take it or leave it, that like the method you use to measure anything , is your choice . In the course of my work I use a Chubb bore gauge ,a split ball gauge for chokes and a plug gauges for chambers. I dont see a problem as they are easy to use and as accurate as nessesary both in the sales shop or in the workshop when boreing, rechambering and when rebuilding barrels. There are always exeptions ,but thats life.

|

|

|

|

|

Joined: Feb 2008

Posts: 1,120 Likes: 27

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 1,120 Likes: 27 |

I have a Brownells 12Ga plug gauge and it usually comes up short in German shotgun chambers such as Sauers, Merkels and Simsons. These are guns made from the 1930s through the 1980s. That is even the case in guns marked 12/70. Most of these shotguns have .724 bores so everything is a little smaller than we're used to here. I have come to rely more on a good eye and an old steel 6" rule as was mentioned above.

But back to the original suggestion, that looks as if it would do just fine to distinguish a quarter inch difference in a shotgun chamber.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Sorry but if you want to measure chamber depths stick to a graduated plug gauge. As a wise American once said "If it aint broke dont fix it." Gunman; Once more "READ" your own post. There simply is no way to read into that anything other than you were saying the plug is the "ONLY" way to do it properly. That is the entire post quoted. Nice to see that you yourself do not follow what you said, but use other methods as circumstance dictate. Never-the-less from the above quote it did need to be pointed out the plug gage was NOT a Cure-All method which was infallible. Remember everyone who monitors this board doesn't have the years of experience measuring chambers which you do. That post left the impression one could simply stick one of the chamber plug gages into any shotgun chamber ever made & if it came up short it needed "Fixing". That is not necessarily so. IF a 2 3/4" chamber "Gages" 2 9/16 just because it is .001" undersize "It Don't need Fixing".

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: May 2010

Posts: 1,530 Likes: 82

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,530 Likes: 82 |

Piper , It was never my intention to have a two sentence comment run on for days.

I see now that I should have made it clear that I was speaking in general terms ,but in my attempts to be both brief and witty I have failed .Without going in to long explanations of what I saw wrong with James'es original post,having had experience of a similar device and knowing its shortcomings ,not wishing to cause any offence to his ideas ,I made my original post that you have subsequently quoted.I still maintain that a plug gauge is the best method of measuring a chamber depth. Yes there are inherent problems and yes if you want to be 100% accurate you would need to measure the chamber diameter at the bottom and turn up a plug of the corresponding size taking into account that you can not put a .810" plug in a.810" hole,etc. etc.

In future posts I will try explain my reasoning in greater detail,so that my comments may hopefully be taken as helpful,rather than dismissive or dictatorial.

|

|

|

|

|