Just my swag. If I were to just assume that the bulge is all the way around and about .017 per side or .034 diameter in an area of the barrel that was .728 bore and .928 O.D., that amount of stretching of the metal comes to about 3% "elongation" in a circumferential direction. If the O.D. is smaller, then the elongation is slightly

less greater.

Just using 4140 normalized as a baseline here, it has around a 18% elongation at failure. Of course, as the elongation gets greater, the material thins, at these higher elongation numbers.

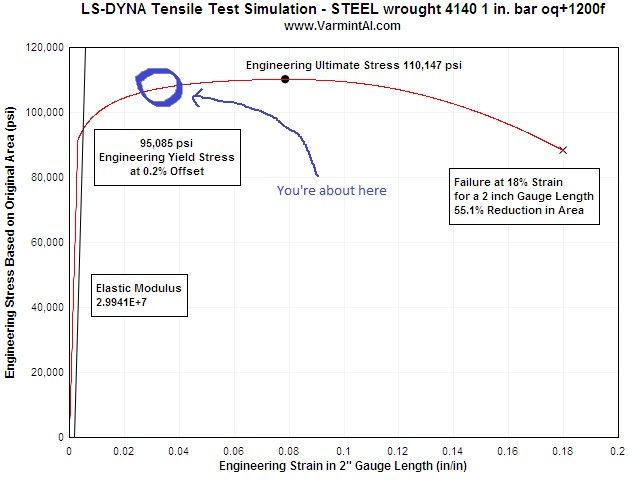

The chart below shows the red line, starting on the left, going nearly vertical but slightly leaned, in a straight line. That is the elastic region where any stretch will return to original shape. When it takes that corner and starts to arc to the right, that corner is the beginning of the plastic (yield point) region. That dot represents the ultimate strength, and the x to the far right is the failure point at 18% elongation.

If you draw a line straight up from the mid point between 0.02 and 0.04 on the bottom (3% elongation), you see that it intersects the red line at about 105,000 psi. To yield it further, it will take 105,000 psi instead of the 95,000 psi it took to yield the not previously yielded normalized steel. The steel becomes slightly stronger from the cold forming at lower yields like yours and up to about 8%.