It took multiple billets to produce a single tube. What you are seeing is a difference in the rate of twist per millimeter.

The ribbons were heated red hot and welded. This was to insure that they were properly joined from the rolling mill. Then they were heated red hot again. This time they placed the ribbon in a perret. This was originally a blade makers tool. The journeyman would twist the ribbon by turning a crank.

The master stood over the red hot ribbon and poured water on it. He was judging the twist per millimeter by eye. This would effectively "freeze" the twist. This process was repeated several times per ribbon.

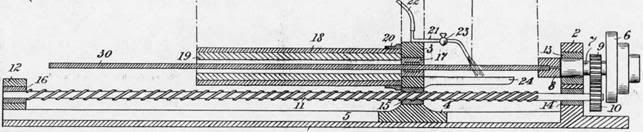

They would turn ribbons for several hours, putting each aside when it was done. Then they would begin the process of joining ribbon into billets, hammering them flat and wrapping them around the mandrel. As they finished a billet, they would put is aside. Finally, they would weld another billet on and complete the wrapping around the mandrel. The mandrel was first covered with an untempered (soft) sheet of iron, a chemise. The billet was literally welded to this chemise. This would prevent the billet from unwrapping as it cooled.

All the time, once they had hammered the billet, they could no longer tell for certain what pattern(s) they were dealing with. Think of it this way. You take a wet towel and twist it, then freeze it. Once frozen you can no longer tell the twist rate, so you take the towel and join them together.

If you look, you will see the basic pattern is the same, it is simply that the twist rate is different, compressing the spaces. The film clearly shows this part of the process.

Later, in certain cases, this very manual twisting process was replaced by a machine. It also goes to the heart of attempting to "name" a damascus pattern. Ultimately, they are all twist or laminated. It was a required part of the process.

"Pattern obsession" was simply not as common then as it is now. Very often the barrels were simply blackened or browned to the point that no pattern was visible. The exception to this was when makers used the pattern to charge more per gun.

Pete