|

|

|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

3 members (earlyriser, Parabola, 1 invisible),

430

guests, and

3

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,823

Posts566,122

Members14,621

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Dec 2006

Posts: 245

Sidelock

|

OP

Sidelock

Joined: Dec 2006

Posts: 245 |

Open question. What is considered today to be a safe chamber wall thinkness in fluid steel barrels? Once I saw a comment in DGJ that .097" was plenty for a 12Ga gun. More recently a review on the 28 Ga RBL in Shooting Sportsman mentioned .065" as beign sufficient. I presume that chrome-moly or chrome-nikel steels have different standards, the latter being usually 11% stronger than the former, allowing for lighter barrels in bespoke guns.

|

|

|

|

|

Joined: Jan 2006

Posts: 15,465 Likes: 89

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,465 Likes: 89 |

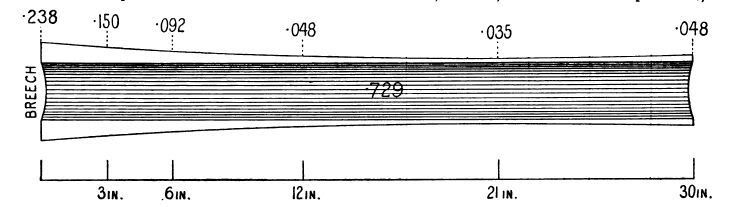

Pete posted this picture a while back...I'm guessing the thickness is different if you are buying or selling. This is a 1891 example of recommended barrel wall thickness. It is a good example of the points that need to be measured.  Pete

|

|

|

|

|

Joined: Dec 2006

Posts: 245

Sidelock

|

OP

Sidelock

Joined: Dec 2006

Posts: 245 |

HJO,

I remember this picture, if memory does not fail me, this were dimensions for damascus.

|

|

|

|

|

Joined: Feb 2002

Posts: 364

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 364 |

Well, it's depends on the gauge. A smaller diameter tube will have less hoop strain. I think that different modern steels used for gun barrels would be all so similar, or nearly so, in strength that there wouldn't be much to choose between them regarding weight reduction.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

I find that drawing a little hard to interpret as it shows a full length cylinder bore, no chamber, no cone & no choke. Few 1891 guns had a 3" chamber. An old Sportsman's Encyclopedia I have gave a recommended min supposedly from the German Proof house of 2.3mm (.090") at end of chamber (regardless of length of chamber) for ordinary steels. For special High strength steels it was said this could be reduced by no more than .2mm (.083"). For 28ga & smaller a slightly thicker wall was recommended. While true the smaller radius results in an increase of hoop strength, it is equally true the smaller bore are frequently loaded to higher pressures. Apparently this was considered self compensating down through about 20 ga, but as the bore went smaller pressures increased more than hoop strength, thus need a slightly thicker wall. 2.5mm (.098") & 2.3mm (.090") respectfully as I recall.

I have seen very few guns having a wall of .150" over the end of chamber. Most I have measured except for very lightweight guns seem to go from .100" to .125".

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Dec 2006

Posts: 245

Sidelock

|

OP

Sidelock

Joined: Dec 2006

Posts: 245 |

2-Piper: thanks for openning fire....

As to the wider audience:

Come on gents, lets get to the hard figures, your acquiantance with proof houses, gunmakers and gunsmiths of note should have left you with some valuable knowledge on this matter.

|

|

|

|

|

Joined: Apr 2002

Posts: 6,812

Sidelock

|

Sidelock

Joined: Apr 2002

Posts: 6,812 |

This is no "harder" data than that which you get out of a bore with a wall thickness gauge. Not just recs or specs. Is there any particular make, model, gauge, era of gun about which you wish to know the numbers before the cone? I've always just gone by Pipes' "90 thou is acceptable and a tenth is better". Course the 9" from hither and yon could also mean something as 9" from breech is getting out there toward the forward hand. 9" from muzzle? What could it matter as many modern target shotguns are perfmetal out there anyway?

jack

|

|

|

|

|

Joined: Feb 2006

Posts: 1,611 Likes: 15

Sidelock

|

Sidelock

Joined: Feb 2006

Posts: 1,611 Likes: 15 |

I've said it before and have been doubted but will say it again - and I just finished taking measurements of the wall thickness of my 1894 Parker GHE 0-frame Damascus barreled 16 gauge and my readings are the same as those taken by Oscar Gaddy some six or seven years ago when he declared my barrels "probably safe to shoot with loads up to about 6,500 p.s.i." which are .067" and .069" at the beginning of the cone of the 2 1/2" chambers. I have shot this gun for many rounds of skeet and upland hunting for grouse and woodcock with appropriate loads as Oscar suggested.

Last edited by DAM16SXS; 06/23/09 10:15 PM.

|

|

|

|

|

Joined: Dec 2006

Posts: 629 Likes: 1

Sidelock

|

Sidelock

Joined: Dec 2006

Posts: 629 Likes: 1 |

I have a 20 ga damascus A&N with .075" at the end of the 2 3/4 chambers proofed in England to 950 bar and I have shot it with RST low pressure a few times. I have Briley tubes in 28 ga for it to feel a little safer although the tubes are aluminum except for the chambers which are steel. I think this is extreme as is DAM's 16 ga.

My Ruger Gold Label measures .15" at the end of the 3" chamber.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Note that when we speak of minimums, this is not necessarily meaning anything thinner will "Burst", but allows for a "Safety Factor". W W Greener reported on page 579 of 9th edition turning a 12ga bbl down till it measured .050" at chamber/cone juncture. It Bulged "Slightly" after "Repeated" firing with 3¼ drams of "Best Alliance #4 powder with 1¼ oz shot.

It is also I think worthy of note, that formulas for determing hoop strength vs pressure are nearly always calculated for "Static Pressure". When pressure is applied to steel it has to first "Stretch" beyond the elastic (Bulging) limit & then Ultimate (Bursting) limit. This can be somewhat understood by realizing how pressures recorded simultaneously by the Lead Crusher & Piezo Electric Tranducer methods do not record the same pressures. The time the pressure is applied is of such short duration even the lead is not compresed to the extent the pressure read by the tranducer would indicate.

Upon firing a shell thusly the bbl does not "Swell" to the extent it would if the same pressure as the max pressure generated were applied as a static load.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

|

|