Since I haven�t posted much in the last little while, I thought you might find this interesting

Almost new Spanish 16 bore, with a stiff price tag I might add, I figured the innards would be a bit sloppy but this is a bit too much

Who�s the maker you ask?.....well, I�ll just say that it starts with A and ends with A

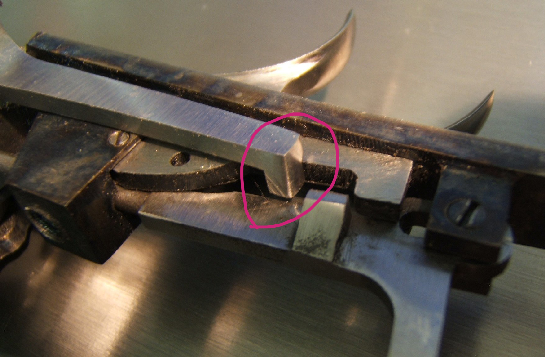

This is the correct placement of the sear sitting squarely on the trigger blade

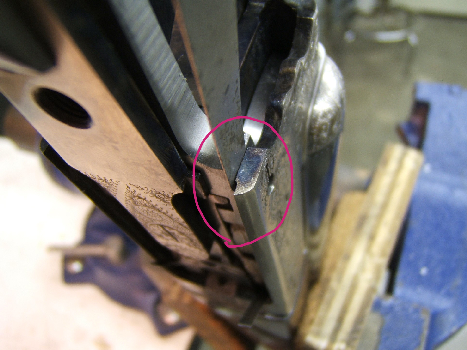

The right side has a big gap, and a sloppy fit btween the pin and the hole in the sear, this creates a problem, notice I can fit a .015� feeler gage (that�s 15 thou) too much

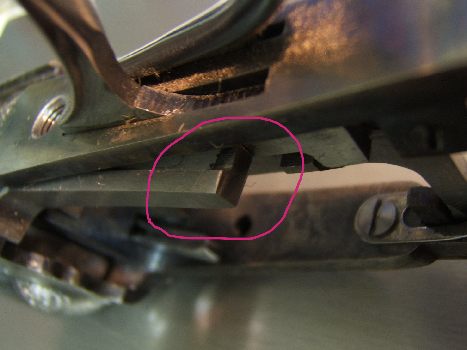

This is what happens because of the big gapand the poor pin fit, the sear slips out and it jams against the inside wall of the stock

Well here you go�not as easy as the pictures make it look but turned out perfect.

Turn a brass slave post and temporarily solder in sear in place to ensure perfect boring alignment

Bore out old hole

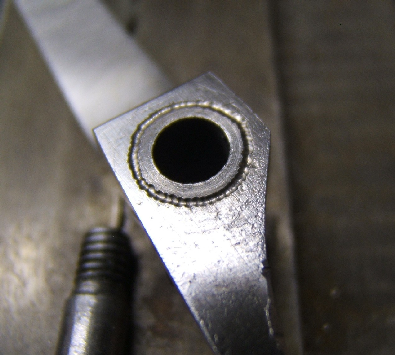

Perfectly bored oversize hole

Turn new tool steel sleeve

Turn new tool steel sleeve...lap fit inside and outside diameters, sleeve to screw and screw to sear

Trim sleeve to proper width (wider than sear) to take up side to side slack and chamfer for welding

Laser fuse sleeve ( both sides ) to sear

Perfect fit�no lateral movement, also (not pictured) trigger pull needed to be re-set as it was too light once sear found its new position

Better than new....I thought!

CJ