Has anyone gone through the effort to figure out safe minimums at each point from the breech so that there is something more reliable than an overall minimum thickness number?

Not to my knowledge. At least nothing that has ever been published. Ultimately the gun designer has to know what material will be used in the barrel. Once that is known everything else follows.

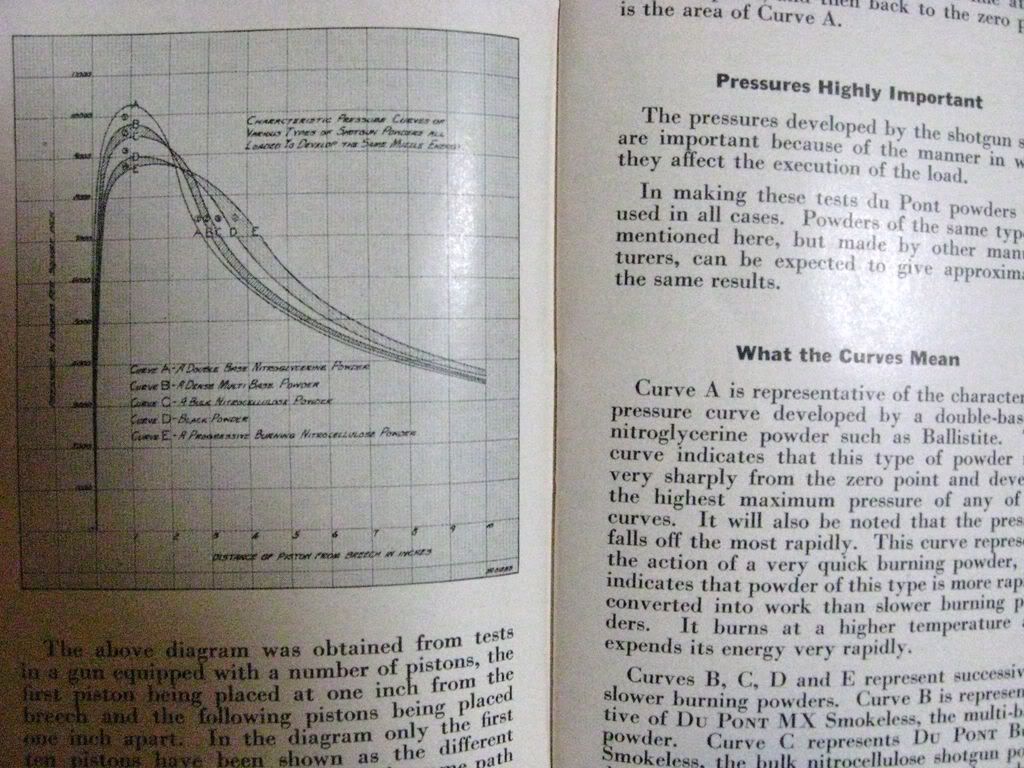

Now about the DuPont chart...

I have been through this booklet several times. I am 100% sure that they state they used lead crushers to obtain their data.

To the best of my knowledge, piezo was not in common use then. It would have been easy to create a probe that could be correlated to lead, copper or whatever you choose. The equipment, ie oscilliscope, they used was primitive by today's standard. Limited to about 10mhz, single trace, no memory, etc...

There was a serious discussion in the literature circa 1915 about the lead crusher standard of the day. It was fully recognized that lead crusher was a flawed method. Mainly because it had a built-in inertia which prevented the capture of smaller values. This shows in the chart, they stop at 10" from the breech. Not because they considered the data irrelevant, but because they knew the lead crusher system would not give them accurate information below about 3,000 psi.

As Larry B has pointed out in the past. They had so much data based on the lead crusher method, they could not bring themselves to simply walk away from it.

For my own use, I will not knowingly fire a gun that has had the chambers tampered with. I measure my guns to be sure of wall thickness. I do not trust a dealer nor those in their employee with my fingers.

If I want to shoot the heaviest loads, I have a Baikal for that. Built like a tank!

Pete