|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

3 members (WJW, steve f, 1 invisible),

297

guests, and

3

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,846

Posts566,500

Members14,626

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Feb 2002

Posts: 364

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 364 |

Concerning G&H, a few months ago I posted about looking at a gun there and when I asked them to measure wall thickness it came to .014". I said too thin for me, they put it back in the rack. I like G&H. This isn't a judgment on their business practice, I expect all gun dealers would do the same. Let the buyer beware.

nial

|

|

|

|

|

Joined: Oct 2006

Posts: 1,544

Sidelock

|

Sidelock

Joined: Oct 2006

Posts: 1,544 |

I just examined a Boss SLE at Holt's with a minimum wall thickness of 14 thou. It had a visible rivvel (not a ring bulge but a distortion of the metal) which I could see clearly at the thin spot, probably where a dent had been raised - the proof house inspector must have missed it. The gun had 2011 proof marks on it. It should not have passed proof. It needed sleeving or re-barreling.

The proof house has no interest in wall thickness. If the material is strong enough to withstand proof charges it can be one thou thick, it will pass - if it is not strong enough at 45 thou thick it will fail.

You cannot guess wall thickness by looking at the gun. You have to measure the walls carefully. It is very difficult to blow up a well made gun forward of the chambers just because the walls are thin. However, it is not uncommon for them to develop bulges and rivvels and dents as a result of their thinness. This is a concern as to value.

The Boss in question sold for £7,000 plus commission. With walls measuring 24 thou or more it was a good enough example to command a total price of over £20,000.

Buying a gun with thin but functionally adequate walls is a means of having and shooting a top quality gun for low quality money. A client of mine keeps a Lang Imperial sidelock here. He shoots it every time he visits from N.Z. It cost £3,000 because it has one wall down to 18 thou. With thicker walls it would be a £10,000 gun.

He made the informed choice that rather than a very solid but ordinary boxlock ejector with thick barrels, he wanted a best quality sidelock ejector for the same money to use when he visited the UK for driven and walked up game shooting. It works, it was a good choice and he paid the right money for it because he was in possession of all the facts when he made he purchase.

There is no 'right answer' on wall thickness, there are informed choices to be made and to make them one needs to in possession of all the data and have the knowledge and understanding of it to make them.

|

|

|

|

|

Joined: Feb 2006

Posts: 3,859 Likes: 121

Sidelock

|

Sidelock

Joined: Feb 2006

Posts: 3,859 Likes: 121 |

Diggory, very good explanation, but for you there, in order to sell a gun it has to pass proof. Here there is no such thing, and in my opinion if a seller sells a gun with known bores of .020 or less (seven sheets of standard printer paper), especially within the first 17" of breech, that is unjustifiable and shows he/they are only interested in the money and not your safe being.

Here we have a variety of people, and hopefully the ones buying these old vintage doubles have some common sense in the type of shells they use in them, but there are always some that don't.

The old saying Caveat Emptor should not apply to guns with less than minimum wall thickness, and sellers should realize this.

Just my opinion.

David

|

|

|

|

|

Joined: Oct 2006

Posts: 1,544

Sidelock

|

Sidelock

Joined: Oct 2006

Posts: 1,544 |

The situation in the US is a little different as you say. The proof laws offer a little safety net and ensure new guns are fit for purpose before they can be sold.

Everything has avalue and it is legitimate to sell any old item. The key issue is disclosure for the responsible seller. The key issue is caveat emptor for the careful buyer.

For example, I will happily buy a thin gun for the right price - I may decide I can do well by sleeving it. If I do not realise it is thin and pay too much for it - then I would be foolish and fools and their money are soon parted.

As a responsible dealer, I would always provide all the data required and advise ignorant customers of the shortcomings of the guns in question, as reflected in their pricing, and try to fit the needs of each customer to the hardware available according to their means or willingness to pay. Not all dealers or private sellers can or will do this.

Therefore, the onus on the buyer is always to educate himself about the equipment he intends to buy (whatever it is) or enrol the help of someone who does to advise him.

I know a little about classic motorcycles but if I were about to spend £10,000 on a Brough Superior, I'd have a friend with me who renovates and races them to pick up all the important stuff I would miss.

|

|

|

|

|

Joined: Oct 2003

Posts: 638 Likes: 2

Sidelock

|

Sidelock

Joined: Oct 2003

Posts: 638 Likes: 2 |

Out of interest,from 1891 so more than likely Damascus barrels?

Last edited by Gregdownunder; 12/18/11 02:09 PM.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,863 Likes: 506

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,863 Likes: 506 |

No Greg; fluid steel barrels including Whitworth and Siemens were part of the 1891 Birmingham Proof House Trial https://docs.google.com/Doc?id=dfg2hmx7_242cxhh9hfq

Last edited by Drew Hause; 12/18/11 02:34 PM.

|

|

|

|

|

Joined: Oct 2003

Posts: 638 Likes: 2

Sidelock

|

Sidelock

Joined: Oct 2003

Posts: 638 Likes: 2 |

Yes,I was just pointing out that these thicknesses would have been considered fairly normal for Damascus or steel barrels at the time?

I expect nowadays modern barrels would possibly be thinner at the breech due to stronger steels.

|

|

|

|

|

Joined: Jul 2010

Posts: 707

Sidelock

|

OP

Sidelock

Joined: Jul 2010

Posts: 707 |

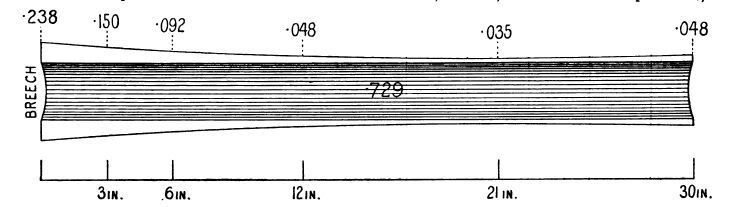

Greg, I've seen that photo before and I think it is of great help. Since it doesn't provide a measurement at 8", and since that is a common measurement area, would it be reasonable to estimate that it would be .070" at 9" from Breech? And .081 at 7.5" from the Breech? Thus, at 8.25" from Breech it would be

.075"? I could extrapolate what 8" would be with a spreadsheet ASSUMING that loss of metal to the walls is consistent in the gaps on the drawing above.

I've heard before that you want to be at .045" to .050" at 8" from the breech but I could never identify the reference that drew that conclusion, I merely am repeating folklore.

Above all, I want to:

A.) Be safe

B.) Buy safe, usable guns that may be overlooked as having too thin of a minimal wall, provided that it truly is a safe gun where the metal really counts. (e.g. more metal further towards the breech, why would I care if it is .020" in a cylinder bore 2" from the muzzle?)

The other question I have for the group is, does math help tell the story? What I mean by that is that I've heard some guns (e.g. old Boss) were made very thin from the onset. I have a Boss hammer gun with .025" minimum walls and the bore diameter is pretty close to .729, and it's marked as a 12 bore on its original proof. Wouldn't the math involved say that if it left the factory as a marginal bore diameter of .729 and therefore it is likely it was born fairly close to a .025 minimal wall thickness?

What is the most common bore diameter for a vintage English 12 bore (actual bore) that was proofed as .729/12 ? Would they have been likely to be about .725 on average at factory new? .720? Or .728"?

The reason I suppose this is important to know is in order to determine just how much of the bore has been removed from honing over a century of use and what was the likely reduction in metal over that period of time. If someone could provide a reasonable estimate of how these .729" guns were really bored, we'd probably be able to estimate how the wall thicknesses probably were originally too, compared to where they measure now.

|

|

|

|

|

Joined: Feb 2006

Posts: 3,859 Likes: 121

Sidelock

|

Sidelock

Joined: Feb 2006

Posts: 3,859 Likes: 121 |

Diggory, "As a responsible dealer, I would always provide all the data required and advise ignorant customers of the shortcomings of the guns in question, as reflected in their pricing, and try to fit the needs of each customer to the hardware available according to their means or willingness to pay. Not all dealers or private sellers can or will do this."

Well spoken. Also, some people that do not have the knowledge, depend on dealers or sellers to give me the correct information about a particular gun they might be interested in. This is especially true with Internet sales.

I would buy from you in a heartbeat, even before this posting, as you always have given very sound advice. But lately I have heard some nasty stories about some of the "big time" dealers that are well known on this site as not doing the same etiquette thing. If they puchased gun at a good price and knew about problems of barrel wall thickness, and now try to pass gun off at a far greater value, that is wrong.

Just a rant, and I guess it will always be so.

David

|

|

|

|

|

Joined: Oct 2003

Posts: 638 Likes: 2

Sidelock

|

Sidelock

Joined: Oct 2003

Posts: 638 Likes: 2 |

As I understand it a bore proved and marked 12,as opposed to 12/1 or 13/1 would have taken a .729 plug and not a .740 plug when gauged.

Therefore actual bore diameter could be anything from .729 to .739 from new.

It seems very common for older black powder hammer guns to be proved as 13 or 13/1 bores.

I even had one that was a 14 bore .

As has been mentioned previously it is virtually impossible to burst a normal barrel much forward of the chamber from pressure alone.

In order to do that the pressure at the breech would have been such that it or the action would give way first.

However Burrard does point out that very thin barrels can give way from normal pressures but he was talking paper thin or heavily pitted in a concentrated area.

Interestingly he goes on to say such bursts are notable for their lack of violence,said barrels just peeling open.

Not that I would particularly want my hand there at the time,violent or not.

Personally I would quite happily shoot a sound barrel honed out of proof so long as the chamber was original and free from pitting and the wall thickness was fairly normal.

Besides this is all you can do with an American made gun is it not?

|

|

|

|

|