|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

3 members (SKB, ithaca1, 1 invisible),

736

guests, and

4

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,817

Posts566,011

Members14,620

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Feb 2012

Posts: 70

Sidelock

|

Sidelock

Joined: Feb 2012

Posts: 70 |

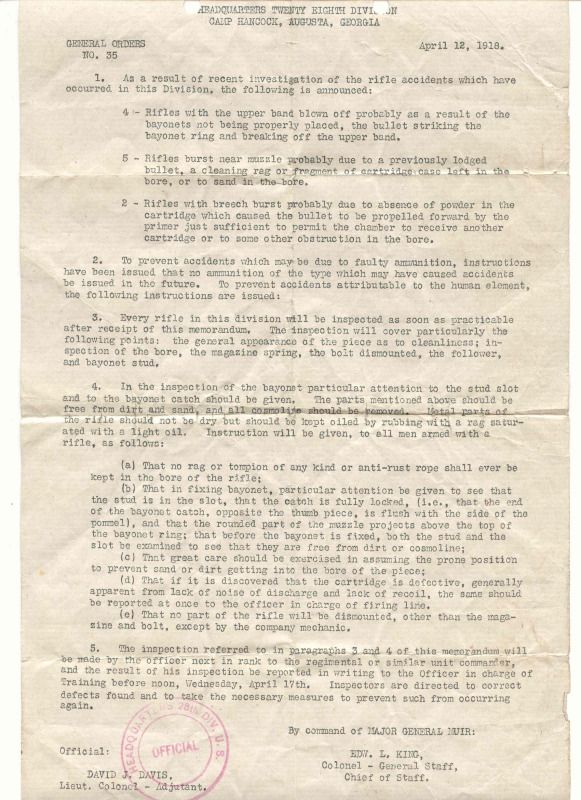

OPERATION 91 CASEHARDENING

Description of Operation--Packed in new,whole bone, heated to 750 deg. c. (1,382 deg. F.) and heated for 2 12 to 3 hr. Apparatus and Equipment: Used--Brown & Sharpe furnaces for crude oil 10 to 14 lb. air pressue: firebox 30 x 45 in.: cast-steel boxes hold 42 receivers: quenched in oil." page 80

This heat treatment process is called "Pack Carburizing", and is normally carried out at much greater temperatures, typically 1700 F and above. Carburizing is a time-temperature dependent process; the conditions stated above are just barely adequate to impart a few thousandths of case depth. It is hard to see how steel could be "burned" in such conditions. First of all, there is no oxidizing atmosphere present. Second, the temperature, 1385 F, is too low to cause excess oxidation if an oxidizing atmosphere were present. It is interesting that the original HT process did not include a tempering operation. That means that the very thin carburized case consists mostly of untempered martensite, and probably, ferrite and retained austenite. This thin layer would be quite hard and brittle. More importantly, the bulk of the steel underlying the case would have low ductility as well. There is a phenomenon called Temper Embrittlement which may account for some of the problems encountered. Typically, the work piece will exhibit lower notch toughness (increased brittleness) when heat treated at a low temperature. This can be avoided by increasing the case hardening temperature, and increasing the cooling rate. The oil quench used in the above HT process is relatively mild, and does not cool the interior of the work piece very rapidly. Subsequent re-heat treatment can alleviate the two problems stated above. "The '03 Springfields" by Clark Campbell, p. 18, outlines the double heat treatment procedure: "The fully machined receiver was then surface carbuerized (sic)in bone at 1500 F and oil quenched. Quenching from this temperature (just above the 'critical') hardened the receiver all the way through - but served to 'freeze' the structure of the steel when its grain size was at a minimum. A second heating, this time to only 1300 F, softened the metal throughout but did not affect the grain size. Because a high carbon steel hardens at a slightly lower temperature than a low-carbon steel, quenching in oil from this particular temperature left the low-carbon core soft and tough while hardening the high-carbon 'skin'. A final 'draw' at 350 F took away a bit of the brittleness from the skin." However, if the steel is truly burned, no heat treatment will suffice to render the material non brittle. This condition would most likely occur in the forging process where the material is over heated and over worked. If the steel forging blank is at maximum heat (it would forge easier), and is subjected to high deformation rates (to maximize production, perhaps), the mechanical thermal spike could actually cause melting at the grain boundaries. This is called "incipient melting" and it imparts extreme brittleness to the steel. When this happens, nothing can be done to correct the problem and the steel must be scrapped. According to Hatcher's Notebook, embrittlement was not confined to receivers, but also to barrels. One incident, maybe more, of a barrel burst was attributed to steel "burnt" in the forging process.

Last edited by Carpetsahib; 09/20/12 08:41 AM.

|

|

|

|

|

Joined: Sep 2008

Posts: 1,153

Sidelock

|

Sidelock

Joined: Sep 2008

Posts: 1,153 |

With regard to the '03,,if it's low carbon steel to start with,,and they 'burned' it in the process (burned the carbon out of it),,,wouldn't the end result seem to be a soft, non hardened receiver when quenched? Not the brittle over hardened problem pointed to?

Again just trying to understand. Probably the crystaline molecular structure of the steel actually breaking down. My metallurgy knowledge is sketchy at best but I know that there are several different crystaline forms that the steel assumes according to the carbon content and the temperature treatment. My smithing instructor said that a white sparkling heat would burn the steel so that it had no strength, and I found that statement to be true when I began to fab and temper my own chisels and punches. But, in blacksmith forge-welding, the iron or steel is first heated to a white sparkling heat and then heated still further by the hammer's pounding. So what keeps the resulting wagon wheel tire or whatever from failing? Maybe the much lower load? Regards, Joe

You can lead a man to logic but you can't make him think. NRA Life since 1976. God bless America!

|

|

|

|

|

Joined: Dec 2001

Posts: 6,881

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,881 |

If there were truly burnt receivers it's hard to understand how they got out of Springfield Armory and Rock Island Arsenal.

I have never read a report of any failures on the battlefield WWI or WWII. The Ross had problems in WWI and it was wildly reported.

“Ordnance Went Up Front” by Roy F. Dunlap Samworth 1948 (speaking of low-number rifles) “I saw hundreds of these in the war, used with all types of issue ammunition including armor piercers with a rather high chamber pressures. These low number actions are safe with practically all government and commercial ammunition in .30-06 caliber, with the possible exception of very high-pressured target loads or heavy-bullet hunting cartridges.”

MP Sadly Deceased as of 2/17/2014

|

|

|

|

|

Joined: Feb 2002

Posts: 1,926 Likes: 230

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,926 Likes: 230 |

Thanks to all for the great info.

Maybe the forging (drop forging) rough receiver was 'burned' in a few instances in that early faze of mfg'r.

Can't blame the final HT Dep't. for that problem.

But if I understand what's been posted already, the forging would have been brittle/hard from the 'burn'. Seems like the machine operations to follow would have rejected it for that condition.

This story surely will never go away.

Kind of like 'Is it safe to shoot my damascus barreled shotgun'.

|

|

|

|

|

Joined: Dec 2001

Posts: 6,881

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,881 |

There was a lot of press during WWI about the USA sending men to fight with a rifle not designed for the pressure of the modern 1906 cartridge. One of the New York papers did a big story about it and many articles were published in A&TM by famous folks telling how safe the rifles were. The problem was many recruits saw rifles blowup, actions and barrels turned into junk. These men wrote home about it and firestorm started. May I suggest you read “The Price of Carelessness” by S. Trask Arms and the Man May 4, 1918. “Down in the Small Arms Section, Engineering Bureau, the Ordnance Department in Washington there is a pile of worthless junk that was but lately nearly a score of finely finished, strongly built United States rifles.” “With receivers demolished, ruptured barrels, split stocks, and damaged bolts, they are eloquent evidence of the price the United States Government has to pay, in addition to all the other cost of waging modern war, because the soldiers to whom these rifles were issued were either careless or ignorant.”

Now if you think this is about the low-number 1903 you are mistaken, this is about the Model 1917.

MP Sadly Deceased as of 2/17/2014

|

|

|

|

|

Joined: May 2008

Posts: 8,158 Likes: 114

Sidelock

|

OP

Sidelock

Joined: May 2008

Posts: 8,158 Likes: 114 |

The 1903 I am looking at is a Rock Island receiver sn is 320246 but the barrel is a Feb 1930 Springfield Armory replacement- uncut, in a semi-sporter stock- all mechanics check out well, usual military 2 stage trigger pull- 4 land barrel- vintage??

"The field is the touchstone of the man"..

|

|

|

|

|

Joined: Dec 2008

Posts: 678 Likes: 15

Sidelock

|

Sidelock

Joined: Dec 2008

Posts: 678 Likes: 15 |

RWTF- that isn't even a low number rifle. Rock Island receivers below- and I'm quoting from a suspect memory here- 285,000 were in that category. Those above that, including yours, were made of nickel steel- a different beast entirely, and devoid of any of the aspersions cast toward low numbered guns.

I must say that this has been one of the more civilized discussions of low numbered '03's that I have witnessed in a long time.

|

|

|

|

|

Joined: Dec 2001

Posts: 6,881

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,881 |

I think this unit had 1917's.

MP Sadly Deceased as of 2/17/2014

|

|

|

|

|

Joined: Feb 2002

Posts: 1,926 Likes: 230

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,926 Likes: 230 |

I must say that this has been one of the more civilized discussions of low numbered '03's that I have witnessed in a long time.

I think it's the only one I can ever remember. Not surprised at all it would occur here.

|

|

|

|

|

Joined: Dec 2001

Posts: 6,881

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,881 |

When the USA started drafting men by the hundreds of thousands the training system was just overwhelmed. There was both a shortage of cadre and experience officers with firearms training. The most common cause of action failures during these times was bore obstructions. Although there was a rash of model 1917 action failures at the same time these are now overlooked. All the 1917 action failures were attributed to bore obstructions. A.L. Woodworth (Not Hatcher) did the actual hands-on investigation at Springfield Armory of the 1903’s wrote a report for “Army Ordnance” “The Bursting of Rifles in Service” . Which was reprinted, later in The American Rifleman of December, 1929. In regard to the 1917’s blowing up I would suggest you read “The Price of Carelessness” by S. Trask Arms and the Man May 4, 1918.

I can supply both articles via-email if needed.

MP Sadly Deceased as of 2/17/2014

|

|

|

|

|