|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

2 members (SKB, 1 invisible),

742

guests, and

18

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,806

Posts565,922

Members14,620

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Dec 2001

Posts: 3,553

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,553 |

Very interesting Steve...I wish you the best of luck (Skill, really  thanks franc

|

|

|

|

|

Joined: Feb 2008

Posts: 11,888 Likes: 738

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,888 Likes: 738 |

Steve, this is really amazing stuff. Thanks a million for sharing it with us, and thanks again to Drew and Pete and all of the other researchers who have done so much to salvage the secrets of an almost lost technology. Does anyone have any idea how many man hours it took on average, for LLH or any of the accomplished makers, to make a pair of unfinished Damascus barrels for a shotgun in the late 1800's?

It's pretty sobering to think of how many times I turned my nose up and walked away from very nice shotguns in the past just because they had those nasty unshootable Damascus barrels. In fact, It was only a few weeks before I stumbled upon the Sherman Bell articles in back issues of DGJ that I passed on a very nice star Damascus Lefever in at least B grade at a gun show for a ridiculously low price.

Voting for anti-gun Democrats is dumber than giving treats to a dog that shits on a Persian Rug

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

Keith, There are all sorts of time estimates around. Some consider them written in stone. I think the question needs to more focused, eg 1890 Birmingham, 1900 Liege, etc. Barrel makers were paid by piece work.  So,if you take the above list and figure that the manufacturer had a 100% mark up over his cost. There was the cost of the ribbon from the rolling mill, the 1st barrel makers forge (2 men), the 2nd barrel makers forge (2 men), the grinder, the boring, the inspector, the joiner, the cost of proofing, etc. The barrel makers were making something like 10 cents a barrel. They could turn out maybe 4 barrels in a 10 hour day. How many man hours went into a single set? Steve would be able to make a more educated guess than any one I know. Pete

|

|

|

|

|

Joined: Sep 2012

Posts: 129

Sidelock

|

Sidelock

Joined: Sep 2012

Posts: 129 |

Steve would be able to make a more educated guess than any one I know. Thanks for your vote of confidence, Pete.  Before I would be willing to throw out an estimate of time required to make a barrel, I would want to put a pencil to some calculations. I would be amazed to find that the barrel makers could produce 4 barrels in a day. Off the cuff, I think two barrels a day would be a challenge. One thing that must be considered, is the time required to bring the material to heat in the forge. Nothing happens on the anvil until the steel is at the proper forging temperature. A lot of shop time is used up, just waiting for the metal to come to heat. I can use the movie of the old barrel welders to do some estimates on the number of forging cycles required. Then, use my knowledge of how long it might take to heat a given section of metal to forging temperature. Adding heating time to time on the anvil for each forging cycle should give some reasonable estimates. I've seen some figures published on the number of barrel smiths in a given area, plus the number of barrels produced in a year's time. If these figures can be trusted, it might be possible to back into the time required to make a barrel, by calculating the number of man hours available in that year and dividing by the number of barrels produced. This might be used to verify any calculations that I come up with. Not that is has any relevance to what experienced barrel makers could do; but, I spent six hours at the forge making the small barrel that I produced. I should be considered to be inexperienced, working by myself, using different tools and entirely different forges than the old barrel makers. I was being very slow and methodical with my work. I'm sure an experienced workman could accomplish the same in a lesser amount of time. I also believe that the iron and steel materials used back then were much easier to work with. I'll work on some calculations and post the results here. Probably will take several days, at least.

|

|

|

|

|

Joined: Feb 2008

Posts: 11,888 Likes: 738

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,888 Likes: 738 |

Thanks Pete and Steve. I think a large part of the appreciation I have for vintage doubles is the amount of hand work and craftsmanship that went into making them. As I learn more about the process of producing Damascus barrels, I come to realize just how unaffordable these guns would be to the average guy if built today.

That really never hit home when I was bombarded all my life with so much misinformation by various gun writers about how Damascus was made, and how and why it was so inferior to fluid steel. How many of us spent decades reading that Damascus was just a bunch of (rusty)iron and steel wire wrapped around a mandrel, and heated and hammer welded? That stuff is still being printed in gun magazines today.

I did read somewhere recently that U.S. gun makers were paying around 6-7 times as much for unfinished Damascus tubes vs. fluid steel tubes from European sources. I think the figures were something like $3.50 for Damascus tubes and $.50 for a pair of fluid steel tubes before WWI. I suppose if we knew wage rates and subtracted materials cost and manufacturer profit margins, we could get a rough idea of the total man-hours that went into a pair of Damascus barrels. Supposedly, this large cost difference was part of the motivation for gunmakers to begin the propaganda that Damascus was inferior and even dangerous to shoot with modern ammunition.

Voting for anti-gun Democrats is dumber than giving treats to a dog that shits on a Persian Rug

|

|

|

|

|

Joined: Jan 2006

Posts: 9,844 Likes: 500

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,844 Likes: 500 |

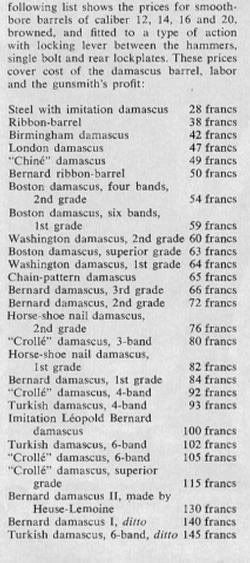

Please note that Pete's Ferdinand Drissen 1897-1898 price list is for finished barrels, but certainly reflects the price differential for the various patterns. The conversion of Belgian francs to U.S. dollars in 1900 was about 5 francs to 1 dollar. The complete charge for the barrels and gunsmithing for '3 band Crolle' was 80 francs or about $16. In 1900, Jean Lejeune of Nessonvaux listed the following prices for damascus barrels alone: 'Oxford'-16f 50 'Boston'-10f (about $2) 'Birmingham'- 8f In 1914, Arthur Delvaux-Heuve of Nessonvaux offered both '3 Band Boston' and 'Starred' for 12 francs 50 and Birmingham (Twist) for 7f 65. The 1902 Sears, Roebuck & Co. catalog lists the Remington 1894 A grade with “two stripe Damascus” for $35. It would would have been much more economical at that time for Remington to source their tubes from Belgium. Steel barrels were introduced on the 1894 Remington Hammerless in the Remington Arms Co. April 1897 catalogue. "Remington Steel" sold for the same price as the ordinary Damascus barrels on A-grade guns. "Ordnance Steel" barrels were offered at the same price as the fancier Damascus barrels on grades C and above, but cost a $10 premium on A- and B-Grades when introduced in 1897, and climbed to $15 by the 1899 catalogue and remained so through the 1909 catalogue. From http://www.la84foundation.org/SportsLibrary/SportingLife/1895/VOL_26_NO_10/SL2610011.pdf we know that the rough forged tubes were paired, wired together, and 40-50 shipped together, but I've never seen what U.S. makers were paying. Most were matching nicer (more attractive or complex patterns, not necessarily stronger) damascus barrels with higher grade guns. The A.J. Aubrey price lists are here http://www.picturetrail.com/sfx/album/view/17474742 and the cheapest had Twist or "Armory Steel". Certainly after WWI the price of damascus tubes increased but I suspect most U.S. makers were using up stock on hand ie. purchased at the c. early 1900s price.

Last edited by Drew Hause; 10/21/12 09:36 AM.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,844 Likes: 500

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,844 Likes: 500 |

Duties on Metals and Manufactures of Metals By United States. Congress. Senate. Committee on Finance 1912 Testimony http://books.google.com/books?id=QDkvAAAAMAAJ&pg=PA893&dq STATEMENT OF MR. W. A. KING, OF MERIDEN, CONN., REPRESENTING THE PARKER BROS. GUN CO. The Chairman. Mr. King, you are the superintendent of the works of the Parker Bros. Gun Co., are you not? Mr. King. Yes, sir. The Chairman. I am informed that you are familiar with the wage question here and abroad. Mr. Kino. Yes, sir; to a very limited extent abroad. The Chairman. I think the committee would like to be enlightened on that point. Mr. King. I can speak only for our own company in so far as wages go. For instance, on the question of barrels, Mr. Hunter informed your committee that some years ago some of the manufacturers of this country attempted to make barrels. We made some barrels: we built an addition to the factory, put in some up-to-date machinery, and brought some men from Belgium to show our blacksmiths how to do it. Wo had to pay our blacksmiths not less than 32 cents an hour, up to 40 cents, and we gave it up, because the highest wages paid the Belgian blacksmiths for exactly the same grade of barrel are 11 cents per hour. That is what is paid to the highest-priced man employed. Senator Smoot. In Belgium? Mr. King, In Belgium: yes, sir. That is where all of our barrels are imported from, with the exception of our very high-grade Whipple (likely a typo for Whitworth) steel barrels. Senator Lodge. Those are rough-bored barrels? Mr. King. Rough-bored only. The Chairman. Do you make any barrels at all? Mr. King. We make no barrels whatever. King may be referring to a late 1870s attempt by Parker to produce laminated steel and twist in house https://docs.google.com/document/edit?id=12y9006Ur7mMCqdeeye89c7L4DQrc2iXR8p4S6OIN1bA

Last edited by Drew Hause; 10/21/12 10:36 AM.

|

|

|

|

|

Joined: Nov 2005

Posts: 4,598

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 4,598 |

I get a big chuckle out of those congressional hearings when I read them. They are talking 11 cents USD. Not sure the exchange rate back then. They also fail to mention the high number of women and children working in their own factories in the USA. None of whom were being paid the rate of a male worker. In Belgium the children were mostly apprentices. They were the children of guild members. Steve, I understand what you are saying. At least by 1924 they had 2 sets of barrel makers at the forge. From the stills I have, there are multiple tubes standing against the wall. However, I am willing to acknowledge the high likelyhood that was the photographer dressing up the scene.  E Heuse-Lemoine in "Manufacture of Damascus Gun Barrels" 1890 claimed that some barrels had to under go 300 heatings, that would be for a single tube. He also states that only master barrel makers ran the forge. Pete

|

|

|

|

|

Joined: Jan 2006

Posts: 9,844 Likes: 500

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,844 Likes: 500 |

Average hourly wage in the U.S. for all industrial workers was $.21 in 1900; but 52% of the total workforce earned less than $.16 hourly. Thomas and Léonard Dombret pounding out a barrel

Last edited by Drew Hause; 10/21/12 03:16 PM.

|

|

|

|

|

Joined: Sep 2012

Posts: 129

Sidelock

|

Sidelock

Joined: Sep 2012

Posts: 129 |

I have realized that I made a misleading statement in my previous post. The six hours that I stated that I spent at the forge making my barrel, was ONLY the time spent welding the riband coil into a solid barrel tube. The six hours does not include the time spent making the damascus billets, drawing the billets into rods, twisting the rods, welding the twisted rods into a riband and winding the riband around a mandrel to form the coil.

300 heats to weld a barrel might be slightly on the high side; but perhaps not exceedingly so. There are many variables that determine how many heats will be necessary. Blacksmithing isn't an exact science and the smith rarely keeps track of the number of heats he needed to complete a forging. It takes what it takes, depending on how the work is progressing.

How long it takes to bring a given section of material to heat is also quite variable. Temperature of the material when placed into the fire, efficiency of the fire and how well it is managed, mass of the material, whether it is a welding heat or a lower temperature shaping heat, etc. Along the length of a barrel tube, the heats may be as short as two minutes near the muzzle and as long as 15 minutes or more at the breech end. Picking a very short average of 3 minutes per heat, times 300 heats, calculates to 15 hours that the barrel was just setting in the fire.

All of these variables are what causes me to hesitate to put into print a statement of how long it took to make a damascus gun barrel. The best I can do, is to calculate the minimum number of heats that I believe the work could be accomplished in and multiply that by a calculated average of time to heat.

The barrel tubes standing against the wall were quite possibly staged. I wouldn't be surprised if many of them were taken off of the scrap heap of useless forgings. I am certain that not all barrel forgings were completed successfully. Things go wrong and some pieces are lost. Even in modern manufacturing, some percentage of product defects and wastage are expected.

|

|

|

|

|