cont. ...

Since I didn't have the patience to wait for custom reloading dies, and since I already own over 300 different sets of dies, I figured I could "mix & match" different dies to reload the 9x58R cases. But first I needed the cases. Here again, I found custom cases would take 2 - 3 to get. I hate waiting.

So, I decided to more forward. There are a very few cartridges that are even close the this strange 9x58R caliber. (none of the several Sauer caliber cases are available) Of the readily available brass, the 303 Savage is close, with only rim thickness being an issue, but the 303 Savage case is .300" too short. Both the 303 British and the 30-40 Krag have rim thickness and rim diameter issues, and both are "oversize" and longer, but the 303 British is still .050" too short. The 30-40 Krag is therefor the "best" choice; but I didn't have any of those, -so I had to use the 303 British. The loaded cartridges near the end of this post, show the bullet's crimping groove in the correct position had the case been the required .050" longer.

Here are the 16+ steps required in making the brass for this caliber. I'll go through the steps for those that might want to make their own 9x58R brass someday, although I doubt many have rifles were made in this caliber.

1. Once fired 303 British case.

2. Resize in a 303 FL Die.

3. Expand neck with a 338 Win Mag die.

4. Expand neck with a 9.3x74R die.

5. Partial resize in an 8x58 FL die.

6. Use "shave die" (modified 303 Savage FL die) to reduce case head. (partial stroke)

7. Use "shave die" to reduce case head. (re-lube & partial stroke)

8. Use "shave die" to reduce case head. (re-lube & final stroke)

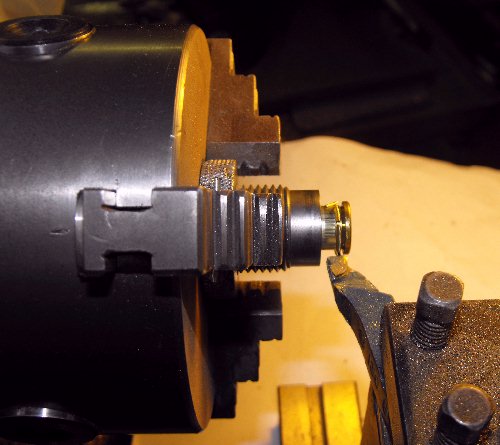

9. Remove curl with lathe.

10. Reduce rim dia with lathe.

11. Thin rim with lathe.

12. Partial resize (modified 30-30 Win FL die)

13. Use "shave die" to reduce case head. (bottom against rim)

14. Cut rim groove with dremel tool cut-off disk and uniform case head (if required) with file.

15. Full length polish case with 360g emery paper.

16. Resize neck & load using 35 Rem Dies.

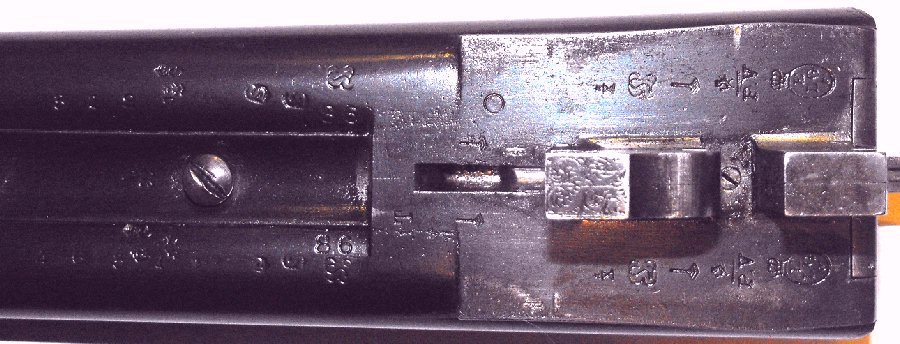

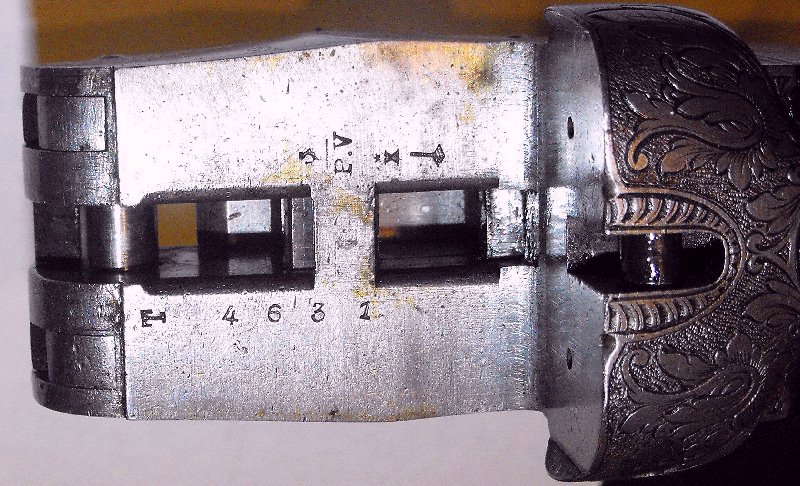

This is the "shave die". It is made from a "cut-off" 303 Savage FL die. The sharp edge of the die, shaves the excess material that is too hard to re-form by sizing. It takes several strokes of the press with re-lubing the case between each stroke. This requires a lot of force and a good press.

After the shave die and case are cleaned to remove the lube, the shave die is used to hold the case for the the several lathe operations to the case head and rim.

cont. ....