cont. ...

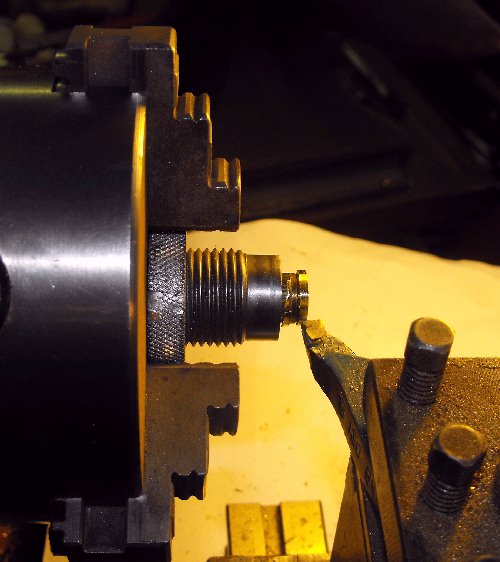

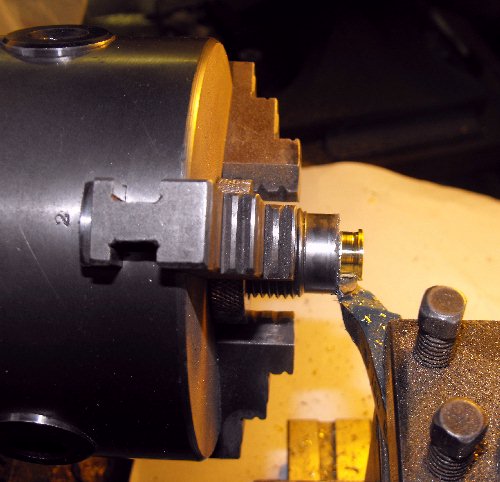

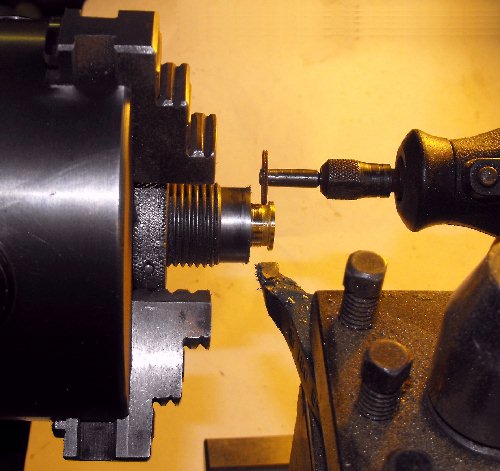

A cut-down 30-30 Win FL die is used for partial resizing of the case body. To fabricate and modify existing dies, I use a dremel tool with a cut-off disk to cut through the reloading dies. Sometimes it requires several cut-off disks to complete the job.

It took approx 5 hours to manufacture 37 cases. I started with 40, but had 3 losses along the way. Although there are a few minor cosmetic variations in the case heads and rims from case-to-case, I don't expect they will affect the function or accuracy when shooting the cartridges.

Later today, I plan to go to the range to test the loads and fire-form the cases for this new addition. Case volume and pressures are very close to that of the 35 Remington, so "starting" data for it was used in working up the loads for this cartridge. I'll keep you posted on the results.

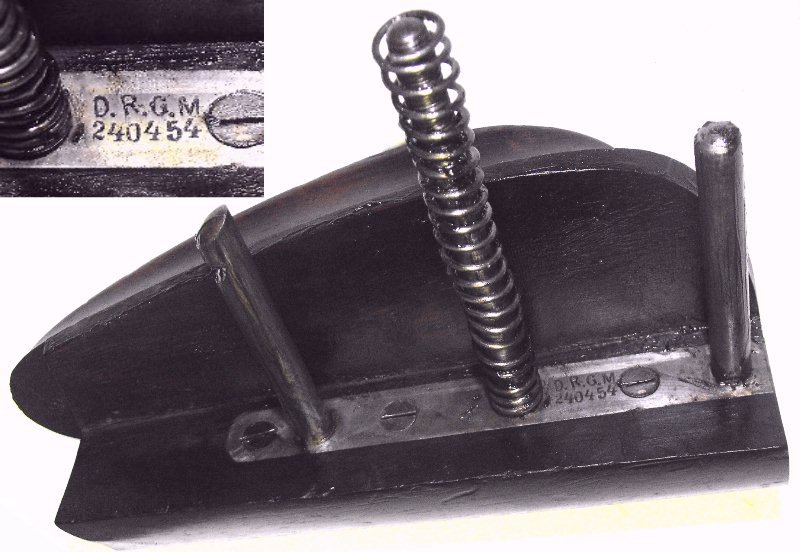

Here are some additional pictures of interest. This is the adjustable cheek-piece removed. You can see the patent number stamped.

On the bottom of the stock, just forward of the cheek-piece height adjusting screw, there is a strange stamp. Looks like a "crown" over a "butterfly". ? ?

If you have enough different loading dies, you can mix-and-match to load just about everything.