I have all of the barrels polished but after the Scotchbrite I found some streaks that have to come out. Additionally, there is some 400 stone work around the scope bases that is needed. Diemaker's stones have been a boon to me for this work. They break down readily but will aggressively remove metal as contours emerge as the machine marks disappear.

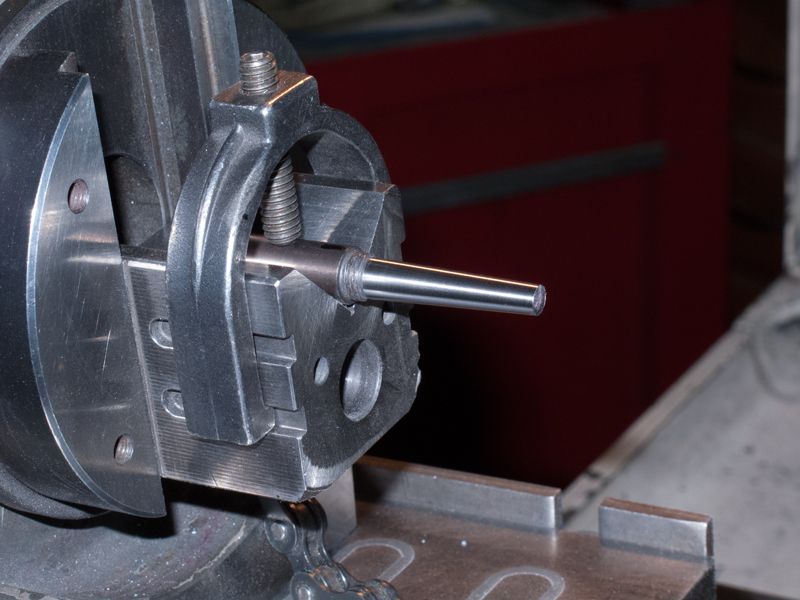

Progress has continued with other parts of the project too. The takedown pin has been ground and it indexes to the same point of rotation with each of the four barrels installed. A lever will need to be designed and welded on and then this part of the project will be done. A spare pin has been ground and fitted and a lever will be welded to it also.

Morris milled the forearm escutcheons today. They mirror the profile of the front scope base, are .200" thick and are set up for a #10 screw diameter using a 5/16" head. The have a 2 1/2 degree draft to ease tight inletting. I need four but as you can see now have some spares. I used a profile like this on another Martini project and liked the look. They are big enough to support an engraved border and some small scroll both front and back of the screw.

I'll start inletting forearms this week. Because of the close tolerances of the barrels a small stock duplicator would be the cat's meow as I would only have to do one and scrape the others in. Oh, well.

Dennis