Just to make it easier for me I will use the Brit wording to describe how to harden �high carbon� steel to the correct state for use. So just this once please and for this exercise only can we meet half way across the pond with the language?

We bloody Brits use the term �hardening and tempering� to describe the simple heat treatment of high carbon steel.

The first part of the statement hardening!!!!! This means that the steel is brought to cherry red in colour in subdued lighting and kept there �soaking� depending on the steel for thirty seconds to about two minutes. Subdued lighting is necessary so you can see the steel colour correctly because if you overheat the metal you can what we say �burn it� this just means that by overheating the metal you can change its characteristics permanently.

After being kept at red heat for the correct time period it is then immersed into either water or oil this can depend on the steel used but what you call �drill rod� and we call �silver steel� you can use either. Now this rapid cooling hardens the steel to what we say is �dead hard� condition, and in this state it is next to useless in fact if you were to give it a heavy blow it would shatter like glass.

Now comes the tempering (Explanation we Brits say �drawing the temper� which translated to modern speak is �moving the temper� from dead hard to a more useful level of hardness.

Ken things are getting a little busy here I have to do a sort of tutorial on how to do a Vintage London stock oil finish that is on the Baikal I have just finished I do sometimes think I should keep quiet!!

WITH ME SO FAR???

GOOD!!

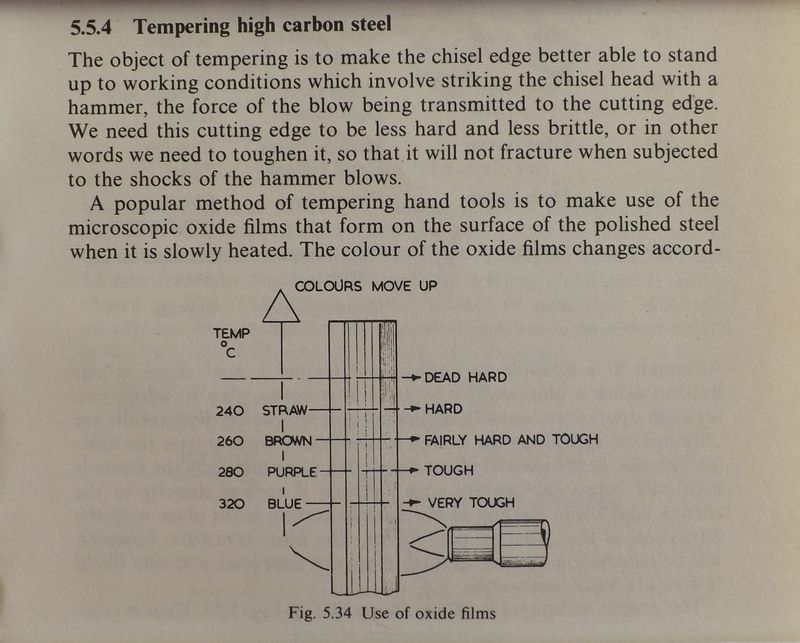

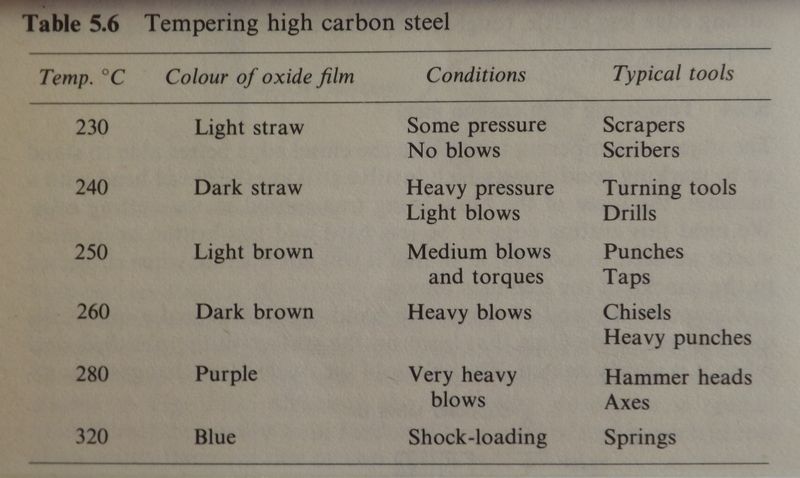

Now To draw the temper we use the surface oxide colours that are formed at different temperatures on the steel as you heat is slowly for the second time that is why you need to polish the surface of the metal you want to adjust the temper of. Now just to throw a spanner in the works this part of the process is also known annealing and after the process of annealing the metal is then annealed. That bloody Brit speak makes things sound so dam complicated.

When you have drawn the temper of the hard steel to let�s say �blue� to make the steel springy ( �good colour for �firing pins� ) the process I rapidly brought to a halt by immersing the steel in water or oil.

Ken Jack Rowe�s method of drawing the temper works on the principal that the Oil flash point at a set temperature. So what he does is heat the steel to cherry red lets it cool give it a polish then immerses it in oil or lard then heats it until it reaches the flashpoint of the animal oil which is roughly about 300oC which is as you can see from the colour chart blue for spring and then quenches it in water. It does work for small springs and single leaf springs but large springs it will not work very well at all.

The sand tray method does not need any oil Ken it just relies on the slow rise in temperature of the sand from the heat source which can be a gas burner or electrical heat source. The idea of the sand is that it is a poor conductor of heat (and Silver sand does not behave like popcorn snapping and banging when heated that is why it is used) so the oxide colours are formed slower and in consequence thicker making them far easier to see, when the colour you are aiming for is reached you stop any further heating by quenching in water.

Now as silly as this may sound it is practically impossible to photograph the colours steel changes to when heated ken they are so subtle. I can only suggest that you obtain some 1/8 inch drill rod and try and make some springs your self.