|

|

|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

1

|

2

|

3

|

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

11

|

12

|

13

|

14

|

15

|

16

|

17

|

|

18

|

19

|

20

|

21

|

22

|

23

|

24

|

|

25

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

2 members (Ted Schefelbein, 1 invisible),

521

guests, and

6

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics39,805

Posts565,891

Members14,620

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Oct 2006

Posts: 236

Sidelock

|

Sidelock

Joined: Oct 2006

Posts: 236 |

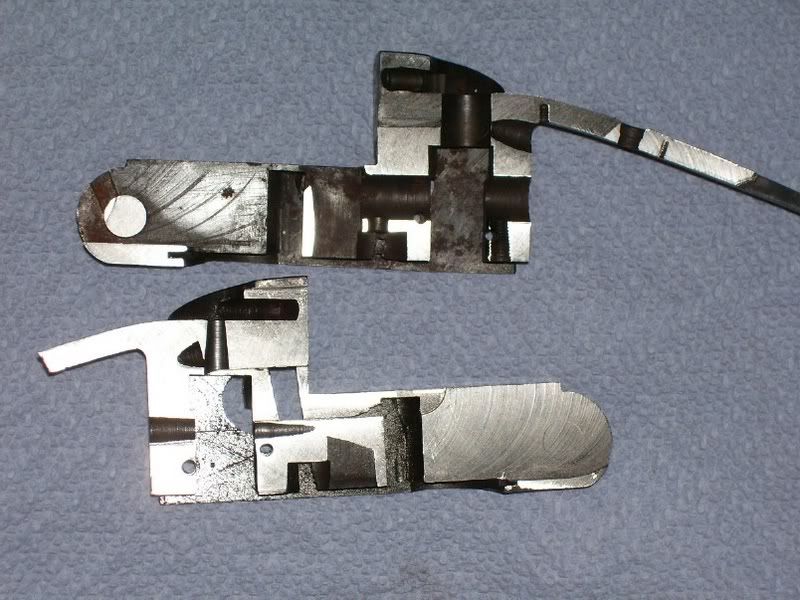

A fellow brought this to me about 15 years ago. He had taken it to work and tried to weld it. It was a 16 gauge. Found another frame and rebuilt it. [img]  [/img] [img]  [/img] [img]  [/img]

|

|

|

|

|

Joined: Oct 2006

Posts: 236

Sidelock

|

Sidelock

Joined: Oct 2006

Posts: 236 |

For those interested the sr# on the 16 gauge was 352618 with the s

16 on the water table.

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Rabbit;

Burrard discusses this in Vol II under the heading; Pressure/Length of Cartridge, beginning on page 152 & ending page 155, much too long for quoting here. In essence as I said he discusses the two different situations of a "True 2 3/4" cartridge & a 2½" load put up in a 2 3/4" case as entirely seperate entites. Thoms did not make this distiction when quoting him but treated his statements on the True 2 3/4" load as applying across the board.

Whether this was intentional or merely lack of complete research, is really immaterial as far as I'm concerned, it simply fails to inspire confidence in a man of his supposed position who either doesn't know whereof he "Quotes" or intentionally misquotes.

Fact is it was sttled in GB about 1938 & re-affirmed around 1946 (After the War) that if the regular 2½" load was put up in a paper case of 2 3/4" length & closed with a fold crimp, giving a "loaded" cartridge of normal length for the 2½" chamber both pressure, ballistics & pattern were essentially normal. there really was little left for Garwood to investigate in the matter, he simply needed to "Study Burrard". His findings did of course confirm what had already been Confirmed as well as did Bell's all these years later, except I believe he got the same results using plastic cases.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Apr 2002

Posts: 6,812

Sidelock

|

OP

Sidelock

Joined: Apr 2002

Posts: 6,812 |

Don't have VOl II TMS but I've heard this explanation before and it seems reasonable to me. My personal hero is so frequently found to be siren-songed and clay-footed. Maybe something to do with the monthly pressures of the rag-trade?

jack

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Rabbit;

Since you do not have Vol II will give this excerpt from pg 154;

"" In 1938 I tested some of the first lot of british fully crimped paper-tubed cartridges which were issued. These, as has already been explained, were loaded in 2 9/16" cases. I fired a series of ten shots for pressure & obtained very even & perfectly normal results. Two months later I tested another lot which were loaded in 2 3/4" paper-tube cases. The shot charge in both lots was 1 1/16oz & the powder charges were similar. I fired 25 shots for pressure & again obtained a very even series with no higher pressure than those given by the first lot. Since 1946 I have tested many more lots & these results have proved quite definitely that for all practical purposes any increase in pressure due to the longer cartridge case really does not exist provided the correct powder & shot charges for a nominal 2½" cartridge are used. ""

This is quoted directly from Burrards writings. If Thomas ever acknowledged this & if in fact he gave Burrard credit for anything on the subject other than a ""Flat condemnation of "All" use of a 2 3/4" case in a 2½" chambered gun"" I would like to have a quote on it. Given that quote I will retract my statements & appoligize for them. In the meantime I have stated my opinion.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Apr 2002

Posts: 6,812

Sidelock

|

OP

Sidelock

Joined: Apr 2002

Posts: 6,812 |

Miller, the material in the first Gun Book makes no qualifications or fine reasonings about Burrard's "position" as represented by Garwood. To repeat, this material is probably from a monthly article in 1964. I'm wondering if Burrard is at variance with himself between Vols. I and II of The Modern Shotgun. I think I'll read whatever seems pertinent in VOl I. just to see if Vol I is all that Garwood had seen, or remembered, or chose to remember. I really hate to think that you and JL may be right about Garwood playing fast and loose with the truth of some shotgun issues and phenomena but let the chips fall where they may. They always say "steal from the best" but credit where credit's due.

jack

later: Nothing there Vol I. All mechanics; no ballistics. I've probably confused this book with the encyclopedic work of Greener. Need to get Vol. II.

Last edited by rabbit; 06/04/07 10:35 PM.

|

|

|

|

|

Joined: Oct 2006

Posts: 236

Sidelock

|

Sidelock

Joined: Oct 2006

Posts: 236 |

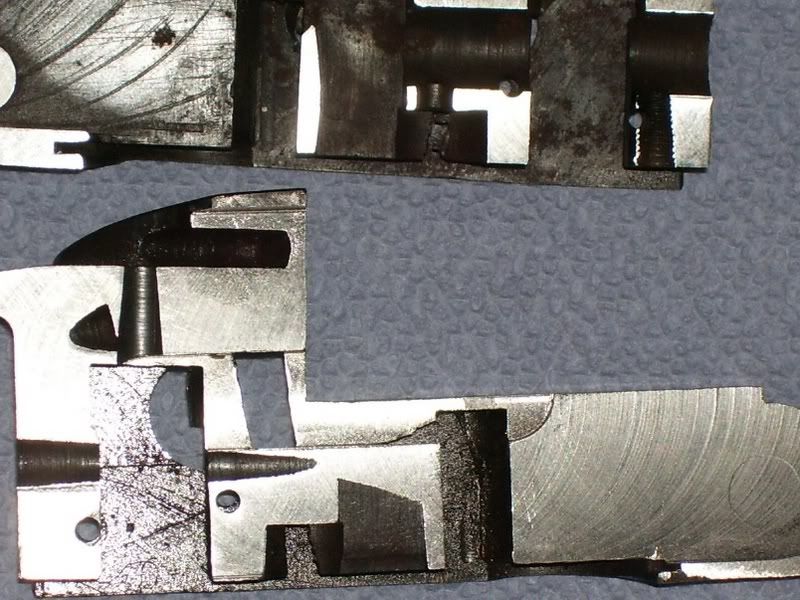

I sectioned the action some more on the 16 gauge. While slitting and milling it became evident that the action was very hard where the water table meets the standing breech. I believe its due to the metal being thinner in this location than anywhere else. If any one can use this sectioned action for a article or teaching purposes i will send it to them free of charge as long as it will be used for a good cause. If any one interested speak up. [img]  [/img]  http://i57.photobucket.com/albums/g211/rshow/sendoutpic1597.jpg" alt="" />[/img] [img]  [/img]

|

|

|

|

|

Joined: Sep 2003

Posts: 2,196 Likes: 20

Sidelock

|

Sidelock

Joined: Sep 2003

Posts: 2,196 Likes: 20 |

I'd think that perhaps our friend Greg T. might like to have that sectioned action, but I would not pretend to speak for him. He'll be along & can do that quite well his self;-)

As a side bar, what's the FFL transfer status on a sectioned action?

Meantime, do you have access to a Rockwell hardness tester? It would be interesting to verify your thots with a series of point tests. Please don't misconstrue my thots .. I do not question your machining observations. Rather, I think it would be interesting to know the actual hardness values on an R scale, that's all. I think it would translate better in that manner and more folks could relate to how much harder.

|

|

|

|

|

Joined: Oct 2006

Posts: 236

Sidelock

|

Sidelock

Joined: Oct 2006

Posts: 236 |

tw There is enough metal cut out to make it a dwatt. We had a Rockwell International plant in our town where i knew a foreman who tested metal for me ,it has since been taken over by Sensus Technologies. I will check with him tomorrow and see if he can still do it. Rich

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

Depending upon the depth of case the hardness could be greater than revealed by a Rockwell tester. Often the point of the diamond on a rockwell machine will break through the case & give a false reading, always softer than actual hardness of the case. There is I believe a D scale which is used on Case Hardened parts. It does require a different penertrator than the normal C scale.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

|

|