|

S |

M |

T |

W |

T |

F |

S |

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

8

|

9

|

10

|

11

|

12

|

13

|

14

|

|

15

|

16

|

17

|

18

|

19

|

20

|

21

|

|

22

|

23

|

24

|

25

|

26

|

27

|

28

|

|

29

|

30

|

31

|

|

|

|

|

|

|

Forums10

Topics39,857

Posts567,705

Members14,635

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

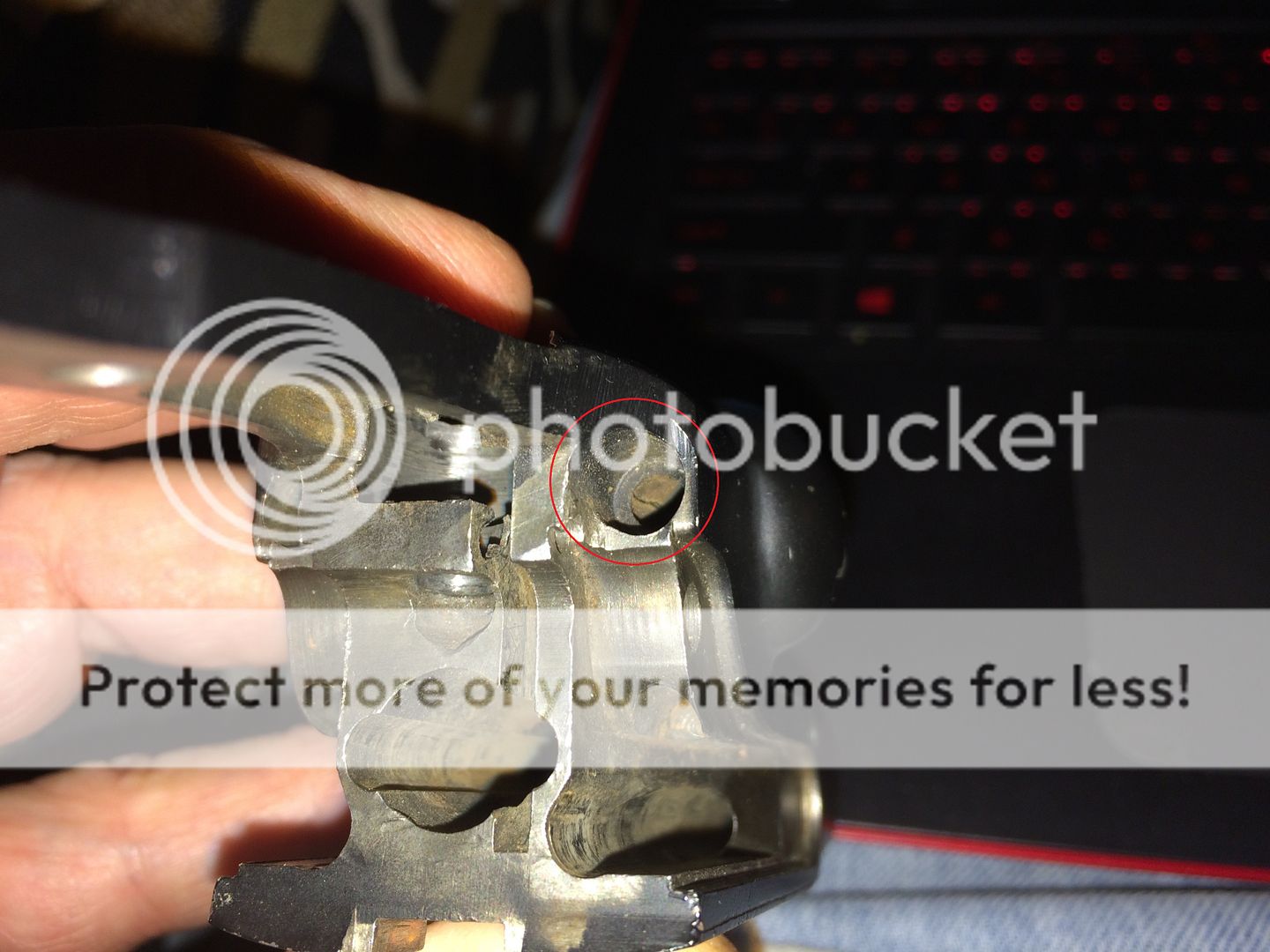

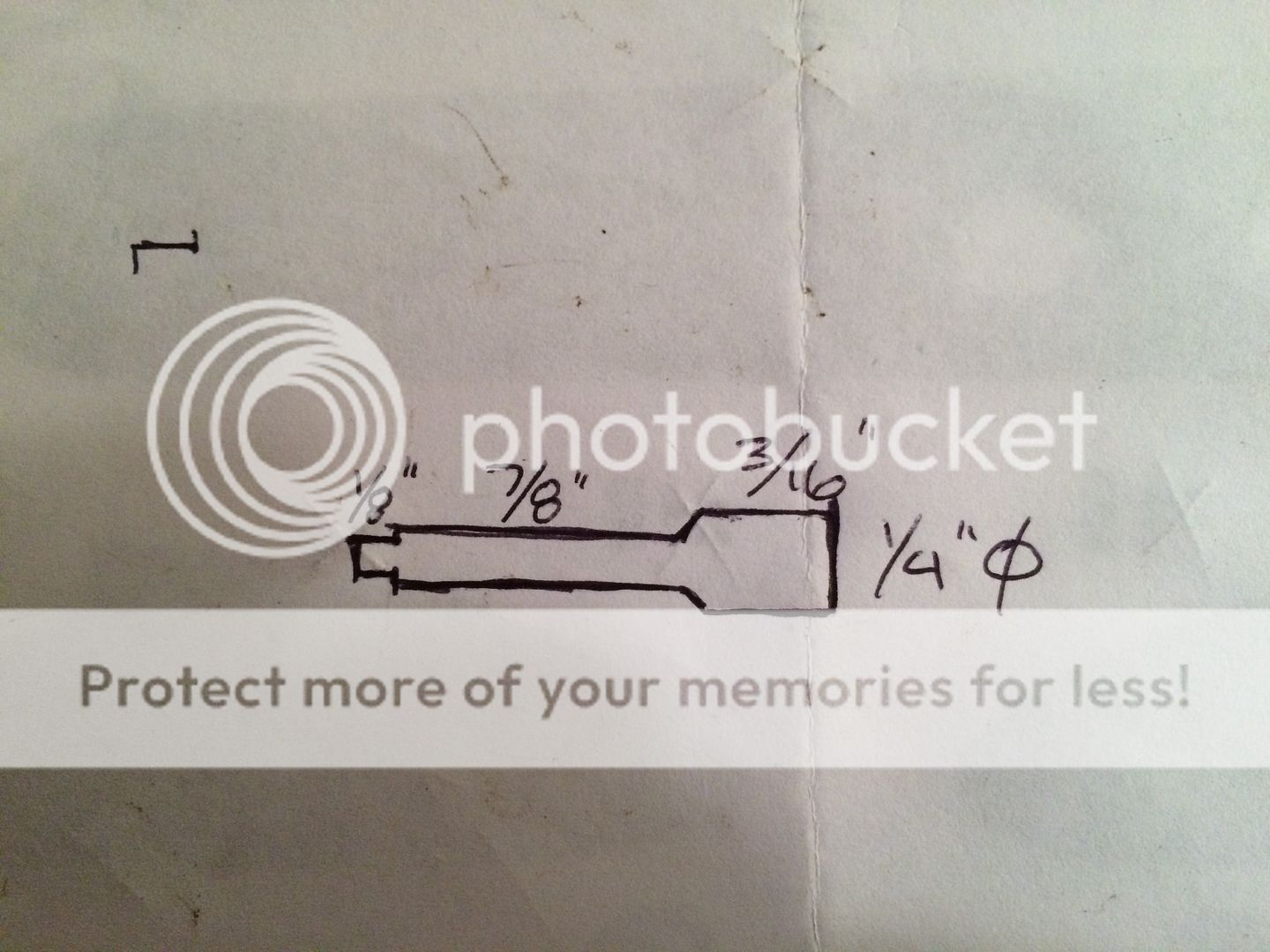

Evening all. I have a post in the gunsmithing section regarding my Meriden 20 ga SxS that I've been working on. The biggest obstacle I have has to do with the firing pins. I'm hoping that someone here has some thoughts or info they can provide. The gun was made around 1917 and it seems there's not a lot of information out on the web and virtually none for a 20 ga. I'm trying to see if I can get this to a point where I can use it but it needs some help. Who knows, maybe it will end up being a wall hanger. There are several parts that are missing besides the firing pins but I'll start my questions there. I was on the Numrich site looking at the schematic for a Meriden gun to see what they showed for firing pins. I bought some parts off Ebay for a 12 ga gun and the firing pins I bought matched what was on their site. Well, it is now evident that not all parts interchange with the 20 ga. Here's what I bought (missing the spring) with the firing pin seat at the top of the picture.  Here's a shot of the receiver with the firing pin hole circled. Note that there are no internal threads for the firing pin seat (retainer) to screw into.  My best attempt at measuring the firing pin recess came up with this:  Wondering if anyone has seen anything like this? How is the firing pin retained? I appreciate any help that anyone can give. Kirk

|

|

|

|

|

Joined: Feb 2002

Posts: 1,935 Likes: 244

Sidelock

|

Sidelock

Joined: Feb 2002

Posts: 1,935 Likes: 244 |

The assembled lock I'd guess.

|

|

|

|

|

Joined: Feb 2004

Posts: 13,883 Likes: 21

Sidelock

|

Sidelock

Joined: Feb 2004

Posts: 13,883 Likes: 21 |

Looks to me like the side plate retains it.

Btw, not all firing pins have springs to retract them.

Last edited by Chuck H; 01/11/16 06:53 AM.

|

|

|

|

|

Joined: Oct 2007

Posts: 534 Likes: 23

Sidelock

|

Sidelock

Joined: Oct 2007

Posts: 534 Likes: 23 |

Kirk,

GPC(Numrich) is notorious for sending "something close" to what you ordered. Ebay, is a crap shoot as items are often mislabeled. The firing pin you received looks like it is for their Hammer model. GPC are good about working from drawings or pictures to find the correct part. I would contact them by email an try to identify your pin from the drawings or pictures.

Can you give us a measurements: Frame width across the flats. Side plate length and height.

If these match 12ga dimensions I will remove the firing pins from one of my Meridens and send you the specs.

John

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Kutter/Chuck, I was more wondering what it was that kept the pin from coming out of the recess. I just assumed that the pin had to be retained. When the side plate is on and uncocked, the hammer is right up against the face of the pin recess. When cocked the face of the hammer is back from the recess about 1/4". Looking at the shape of the recess with the large diameter section only being 3/16", I wouldn't think you'd want that coming out of the recess.

Chuck, just thought there was always a spring. However I was on the LC Smith forum and I read about pushing the pin in before closing the barrels or pointing the gun up and shaking it. Also read about the pins falling out during disassembly.

Thanks

Kirk

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

John, I didn't get the pins from Numrich. They were won off Ebay along with the complete sideplates, trigger, locking bolt, etc for a 12 ga for a hammerless gun. The serial number of this gun is 50460 which puts it at a 1912 vintage. I feel that I have enough 12 ga components that I'm pretty certain they built a specific receiver for the 20 ga. By across the faces I assume you mean through the centerline of the pins? If so, that is 2.02" and the pins are 1" on center. The side plate measures 1.13" x 4.5". Here's a picture compared to the 12 ga I bought which is .17" taller (or wider in this pic).  Here's a picture of the receiver with a mock up of the cocking rod. Looks like the rod for the 12 is .1" taller.  Not sure what I'll do. One thing it seems is that there were very few 20s made. I'll probably also talk to some of the folk on the LC Smith forum to pick their brains how some of them are built. For that matter if anyone on this forum knows of any model that is of similar construction, I'd like to hear from you. Kirk

|

|

|

|

|

Joined: Nov 2005

Posts: 1,274 Likes: 1

Sidelock

|

Sidelock

Joined: Nov 2005

Posts: 1,274 Likes: 1 |

Kirk I am not sure when it happened but later L C Smith firing pins were simply inserted into the hole drilled from the rear, the lock plate retained them, there were no springs. If you were not careful the pins would drop out when the locks were removed. It appears to me that your Meriden used the same system.

I learn something every day, and a lot of times it's that what I learned the day before was wrong

|

|

|

|

|

Joined: May 2008

Posts: 8,158 Likes: 114

Sidelock

|

Sidelock

Joined: May 2008

Posts: 8,158 Likes: 114 |

Firing pin is stepped from main shank to tip- at a 90% angle- but what is the developed angle from the head down to the main shank?

"The field is the touchstone of the man"..

|

|

|

|

|

Joined: Jan 2011

Posts: 101

Sidelock

|

OP

Sidelock

Joined: Jan 2011

Posts: 101 |

Fox, I'm not 100% sure about the change at the tip. Using a flashlight it "looks" like there's a lip and it "feels" like it but exactly what/how is somewhat of a mystery. It looks like the angle is 45 degrees at the head.

I was trying to figure out some way to make a casting of the recess. Not sure what the best material to use would be. Epoxy might be the best but I'd sure hate to get it stuck in there. Thought about trying wax which could be easily removed with a little heat but I'd be concerned about the shaft separating.

Any ideas?

Kirk

|

|

|

|

|

Joined: Oct 2007

Posts: 534 Likes: 23

Sidelock

|

Sidelock

Joined: Oct 2007

Posts: 534 Likes: 23 |

Kirk, My earlier question on measurement was for the width across the frame/watertable flats. From your picture of the two sideplates it is apparent that the 20ga is reduced in height but I cannot determine if it is scaled down in all dimensions. Are the mounting screw and bridle pin locations positioned axactly as the 12ga plate? I took two of my 12ga., Meriden guns apart to take a look. The first, #3142, is marked "The A.J. AUBREY". It has straight cocking Rods vs. the dog legged cocking rods of later guns like yours. Gun #635xx is marked, "THE MERIDEN FIRE ARMS CO." Both have the two piece firing pins, with no spring and a threaded retaining nut(seat). This picture shows the early style(straight) cocking rod. Mid length is a retaining screw in the frame.  Both #3142 & #635xx have identical firing pin assy's retained by a threaded nut(seat).  I went back and looked at your picture above and it does appear that the side plates retain the firing pins in this frame. In the end you may be left to reverse engineering the parts from the frame dimensions. I have an idea on how to modify 12ga cocking rods to work, if the 12ga. "rod" section forward of the offset is the same diameter as your 20ga. frame. John

Last edited by John E; 01/12/16 11:22 AM.

|

|

|

|

|