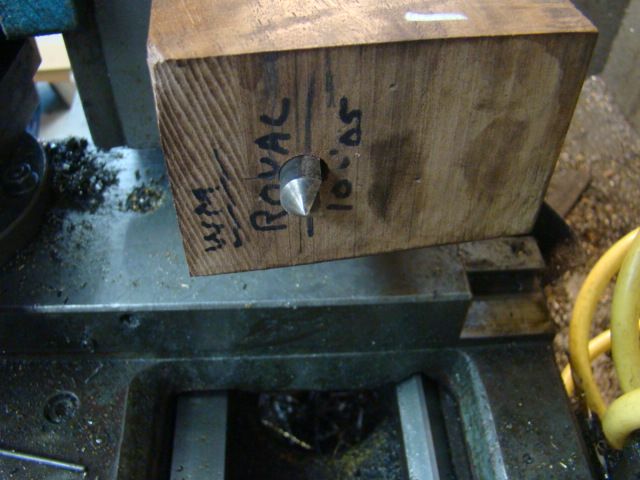

This topic comes up from time to time so I thought I would post my method. Slow feeds and speeds, continually checking alignment are key to getting things to come out properly.The stock blank is clamped in a milling vise attachment, lined up using the tail stock center on one end and the tip of the gun drill bit on the other. You can not rush this operation as heat will build up and if you are not careful you can twist the blank in the milling vise. Patience is your friend on these type of holes.

You can see the bit has now emerged from the blank in exactly where I had planned it. Bushing are now made for both the stock blank and the pattern stock with the through bolt hole being the center for both.

Steve