|

S |

M |

T |

W |

T |

F |

S |

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

|

8

|

9

|

10

|

11

|

12

|

13

|

14

|

|

15

|

16

|

17

|

18

|

19

|

20

|

21

|

|

22

|

23

|

24

|

25

|

26

|

27

|

28

|

|

|

Forums10

Topics39,850

Posts566,570

Members14,627

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

That comes out to be around 2.3 tubes per worker, per day. Twice that if you consider it took two workers to perform the process. This doesn't include Sundays or holidays. Could two men produce five or six tubes per day?

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Feb 2008

Posts: 521 Likes: 4

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 521 Likes: 4 |

DD/N. Please break this down for me. I understand that Nessonveux was a city of barrel making. What stumps me is the distinction between Cannons Delcour (barrels by Delcour?) and Delcours Dupont.

In advance, thanks.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,867 Likes: 507

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,867 Likes: 507 |

Here they are  Jean-Baptiste Delcour-Dupont of Nessonvaux http://www.littlegun.be/arme%20belge/artisans%20identifies%20d/a%20delcour%20dupont%20gb.htmJean-Baptiste was the father of Lucien & Oscar Delcour and had been a manager for Pieper & Cie before opening his own shop specializing in Damascus barrels. He received a patent for SxS barrels in 1910. August 7, 1914 Liege fell to the invading German army. Damascus production soon ceased. Canons Delcour S.A. was registered in 1921, and remained in business until about 1968 when they were acquired by Fabrique National de Herstal. In 1924 Delcour-Dupont attempted to revive Damascus production in Nessonvaux. According to Puraye, the last barrels were made in 1930.

|

|

|

|

|

Joined: Dec 2001

Posts: 2,403 Likes: 17

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 2,403 Likes: 17 |

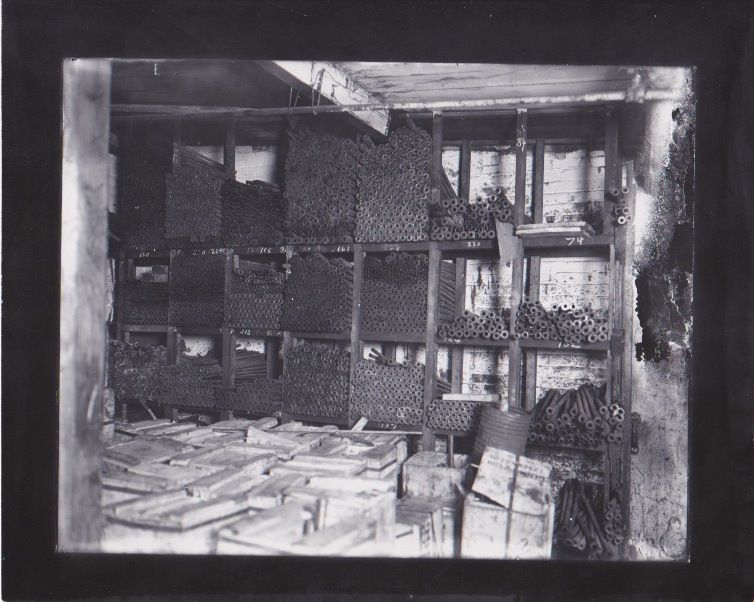

Speaking of imported tubes and boxes of tubes, here is a early photo of the Ithaca Gun Compan'ys barrel store room. I was in this area and the racks were still there but the tubes were long gone.

Last edited by Walter C. Snyder; 12/07/16 08:29 PM.

Walter c. Snyder

|

|

|

|

|

Joined: Mar 2005

Posts: 5,021

Sidelock

|

Sidelock

Joined: Mar 2005

Posts: 5,021 |

OK, we have roughed out round tubes that the American gun manufacturer will finish into shotgun barrels, meaning no Belgium 'Proof' mark, correct?

But, I have an 'LLH' stamp on the bottom of my barrel lump on my Ithaca. Was it stamped in Belgium? And if it was why wouldn't there be a 'Proof' mark on a finished part?

|

|

|

|

|

Joined: Jan 2006

Posts: 9,867 Likes: 507

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,867 Likes: 507 |

ALL "rough forged tubes" passed through Banc D'Epreuves Des Armes a Feu De Liege (Proof House for Firearms of Liege) and were tested with the First Obligatory Proof Load for 12g breech plugged tubes intended for “Double-Barreled Breech-Loading Sporting Guns” with 21 grams = 324 grains = 11.8 Drams black powder and 32 grams = 1.12 oz. shot. They were then (I suspect lightly) stamped with the script EL, and the mark rarely survived barrel grinding/finishing by the U.S. maker This is a Lefever  The 'LLH' was the maker's mark. Hunter Arms frequently just overstamped the mark with the barrel steel. The 'C' is Crucible, but no record exist to know their role as middleman/importer?

|

|

|

|

|

Joined: Jan 2006

Posts: 9,867 Likes: 507

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,867 Likes: 507 |

Thanks Walt. We should probably make the point that, in regard to pattern welded tubes, the U.S. makers were dependent on the Liege tube makers to properly pair tubes for pattern. It is very difficult to discern the pattern of "rough forged tubes"  and even harder if "in the white" so it's easy to understand if barrel patterns don't quite match...or maybe the barrel finisher/joiner grabbed the wrong tube out of the bin on Monday morning after a long weekend  1922 Lefever Arms Co. Nitro Special (introduced in 1921) with fluid steel right and 3 Iron "Oxford" left tube stamped IHR, likely Heuse-Riga Fils known to supply damascus tubes on Flues models. Barrels originally blued. Courtesy of Brad Bachelder.  Remington CEO

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Something to consider about pattern pairing. At the end of the manufacturing process the tubes were coated with sulfuric acid. This does two things. One, it creates a "skin" on the tubes, essentially a protective coating that appears to prevent rusting. If the tubes were then oiled before shipping I doubt any corrosion would occur during shipping. Two, the pattern is very visible, aiding in matching tube patterns. Due to these two points I suspect American makers would be able to make decisions about tube pairings, as the patterns would be visible to them when they made their selections from their stock of rough tubes, even though the tubes were paired in Belgium when they were shipped.

There must have been some percentage of tubes damaged due to shipping, resulting in some guns ending up with mismatched tubes.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,867 Likes: 507

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 9,867 Likes: 507 |

Parker D4 maybe done March 18

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Excellent example of a set that drives the restorer crazy. The differences in crolle size and pattern cause the patterns to "fill" at different rates, the smaller pattern filling much more slowly. Attention to detail of the tiny spiral crolle lines is necessary, to insure the pattern is completely filled.

The Parker D sets I've done all have closely matched patterns, but G grades are a crap shoot. It makes them more challenging, and also more interesting due to pattern variety.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|