|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

31

|

|

|

|

|

|

Forums10

Topics39,714

Posts564,519

Members14,613

| |

Most Online9,918

Jul 28th, 2025

|

|

|

|

Joined: Dec 2001

Posts: 3,604 Likes: 12

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 3,604 Likes: 12 |

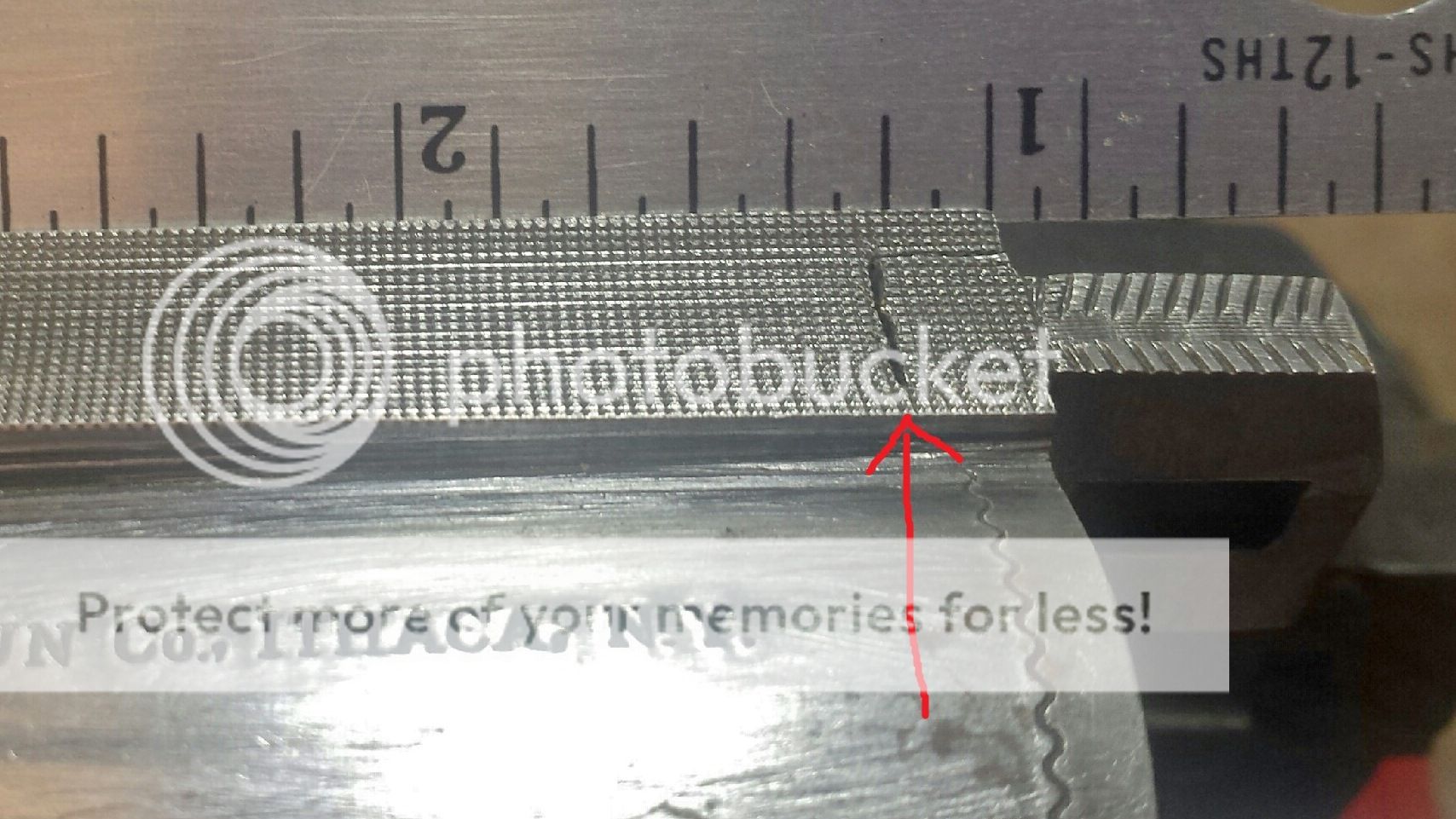

Is this the correct length for an NID extension? Would it have been brazed or soldered?

Mike

|

|

|

|

|

Joined: Feb 2008

Posts: 11,837 Likes: 698

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,837 Likes: 698 |

I have a set of 20 gauge Ithaca Flues barrels that had the rib extension come off. As I recall, it isn't any longer than what you have there on your NID. It has a small alignment pin that goes into a small hole. It looks like it was joined with solder, but a lot of silver brazing solder has the same coloration as regular tin-lead solder. There is a considerable difference in tensile strength in silver solder versus regular tin-lead solders.

Voting for anti-gun Democrats is dumber than giving treats to a dog that shits on a Persian Rug

|

|

|

|

|

Joined: Oct 2004

Posts: 1,826 Likes: 12

Sidelock

|

Sidelock

Joined: Oct 2004

Posts: 1,826 Likes: 12 |

Where as Remington stamped the shot count for each barrel on the bottom of the barrel lugs.

|

|

|

|

|

Joined: Dec 2001

Posts: 3,604 Likes: 12

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 3,604 Likes: 12 |

It looks like it was joined with solder, but a lot of silver brazing solder has the same coloration as regular tin-lead solder. There is a considerable difference in tensile strength in silver solder versus regular tin-lead solders. Yep. That is why I am asking. I have have the needed tools and experience from relaying ribs to repair this........IF it was tin-lead solder. If brazed, then, sadly, this shotgun will get parted out.

Mike

|

|

|

|

|

Joined: May 2008

Posts: 8,158 Likes: 114

Sidelock

|

Sidelock

Joined: May 2008

Posts: 8,158 Likes: 114 |

Thanks for the clarification- but my NID 2E was 2E stamped on the water table, also on one barrel flat-- and 2 on the right side flat, 3 on the left side flat. My Galazan choke gauge confirms this choking as well-- BUT-- if your Ithaca grade 4 has ejectors, as shown by the "split luggers", why didn't Ithaca then mark it as a 4E Grade. Just wondering, as I am too cheap to but a copy of Walter Snyder's book on the Ithaca double guns.. RWTF.

Last edited by Run With The Fox; 05/30/19 06:08 PM.

"The field is the touchstone of the man"..

|

|

|

|

|

Joined: May 2008

Posts: 8,158 Likes: 114

Sidelock

|

Sidelock

Joined: May 2008

Posts: 8,158 Likes: 114 |

Brazing vs. soldering- in the welding trade- silver soldering is done at a lower temperature than either tin alloyed soldering, or brazing-- All these processes do NOT bring the parent metal to its critical temperate range, as does SMAW, MIG and TIG processes. RWTF

"The field is the touchstone of the man"..

|

|

|

|

|

Joined: Feb 2008

Posts: 11,837 Likes: 698

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,837 Likes: 698 |

If that's the case, it would be a shame to just part it out without attempting a repair. I hope someone can answer your question about what was used to braze or solder this rib extension, but I've never seen that specific info anywhere.

I have read that it doesn't take much to hold a shotgun breech closed. Considering the construction of the rib extension of my Flues, I tend to believe that. If you cannot find the specific braze or solder used, I think I might just try some lower temp silver solder, or even Brownells Hi-Force 44. The regular Hi-Force 44 has a tensile strength of 28,000 psi and flows at 475 degrees F. while their Hi-Temp Hi-Force 44 has a tensile strength of 38,000 psi and flows at around 640 degrees F. I'd wire and nail the breech area together to make sure the joints that are sound remain that way. Maybe fill the barrels with water up to the midpoint of the chambers while held vertically to keep the rib joints well below a dangerous temperature. Braze the rib extension back on, and test fire it with the gun tied to an old tire and a long string on the triggers. If it works out... great. If it comes apart, try again with another silver solder... or go with plan B and then part it out.

Voting for anti-gun Democrats is dumber than giving treats to a dog that shits on a Persian Rug

|

|

|

|

|

Joined: Dec 2001

Posts: 3,604 Likes: 12

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 3,604 Likes: 12 |

Hi-Force 44 would be my first choice.

Wouldn't attempt without wire and nails. It is quick to do, so would wire the entire barrel set to be safe.

No worry about the blacking, as it was while stripping the existing that this was discovered.

Probably wouldn't even use the tire. Even if it didn't hold the breech popping open would probably be the worst that happened.

Need to remove the extension(only loose between at top between barrels) to be able to clean the joint properly. And then rinse after acid fluxing.

Mike

|

|

|

|

|

Joined: Dec 2001

Posts: 12,743

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 12,743 |

There is a class of solder which in the machinist trade we always referred to as Silver Solder. These had a melting temp lower than Brazing but well above that of soft solder. One example of these & was a very popular one where I worked was Eazy-Flo 40 if recall correctly. It had a flowing tamp of around 1145° F. It had a much higher tensile than even Force 44 or the Eutectic solder we used. I forget the actual number but it was lead-free & had been designed specifically for the Dairy industry for soldering stainless tubing. Its flow temp was very close to that of Force 44. By being Eutectic that meant that all of its components melted together so you did not go through a "Pastre Phase". Eutectic solders are the easiest type to work with due to this feature.

I am not certain that this category of solder had been developed when that NID was built. Sure looks like a mighty short contact area to me for a soft solder joint to hold up well. I measured a couple of my guns, a J P Clabrough & a Lefever & both had that rib section between 1˝" & 1 5/8". Both are Brazed. These Should Hold till the Cows Come Home.

Miller/TN

I Didn't Say Everything I Said, Yogi Berra

|

|

|

|

|

Joined: Jan 2002

Posts: 5,955 Likes: 154

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 5,955 Likes: 154 |

With J. Stevens using chopper lump barrels from about 1907 onwards --  it seems amazing that our other manufacturers continued to braze bits and pieces together.

|

|

|

|

|