I hope I am not violating the rules by drawing attention to a particular auction. I have seen a number of questionable guns for sell by this same person but I am more interested in opinions of the gun instead of the man that did this to the gun. Should this "low heat and chemical process" be something of concern or is it potentially damaging to the receiver? Could it be easily undone? Overlooking the chopped and rebuilt stock is the torch to the receiver something that lowers the value or would it completely rule the gun out for you?

Ithaca 20 gauge NID

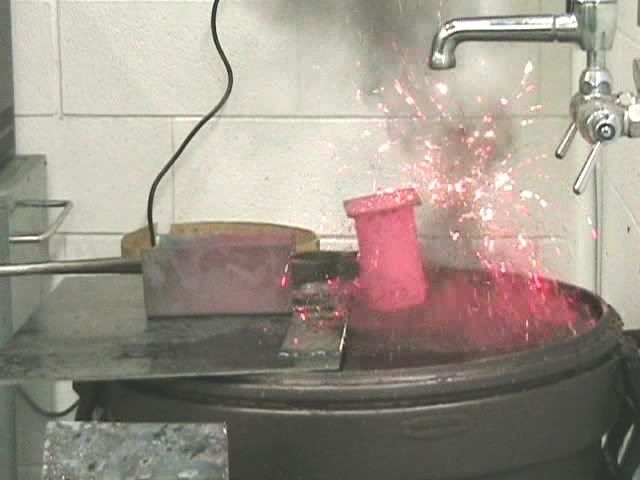

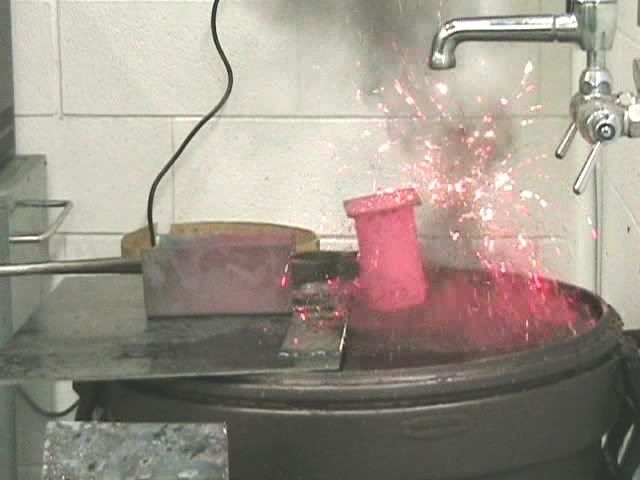

The torch man is at it again.

I don't know what he means by low heat, by the time he heated one spot and went to the others what temperature do you think the receiver was at then?

Dave, you're sick in a good way. "other then that mrs Lincoln how was the play?"

"Overlooking the chopped and rebuilt stock is the torch to the receiver something that lowers the value or would it completely rule the gun out for you?"

"other then that mrs Lincoln how was the play?"

I don't think that would create any change at all in the cyrstal structure of the steel. It looks like garbage and is done with the intent of looking like case hardening to deceive the unknowing buyer; it won't hold up at all, will be gone in a flash and receiver will be gray once more.

I would not buy a spare part from this faux alchemist!

I would not buy a spare part from this faux alchemist!

Nor would I. In fact, in buying a used gun the first thing I might want to know is whether or not Ed Good ever owned it.

Gil, that is what I wanted to know. I didn't know if it was just ugly and could be removed or if it would likely have an adverse affect on the temper of the receiver.

Skip

If the stock had not been cutoff and then spliced, with all the care of his fine metal finishing, that gun would have been a decent buy. He wants $1,200.00 for the gun. If you did not need to replace the stock, then the proper case coloring expense would have been very cost effective. As it is you can not justify several hundred for the recoloring and then several hundred more for a new stock. You would end with over two grand in the gun and never get that much back out of it.

As a shooter is would have been a better buy before the torch. Big Ed1 strikes again.

"Temper" isn't the correct term there. Temper is what you might do to a hardened piece of steel, to remove some hardness, brittleness, as if to a knife blade. The heat from a torch would introduce some carburization; that is strictly on the surface, probably less than .001. Color case hardening is deeper--I think maybe 3-5 thou. But there are others much more knowledgable than I on this subject; I hope they chime in. But the point is that torching the receiver would be less than skin deep and would have no effect (IMO) on the metallurgy; the steel would be fully normalized after the procedure--the crystal stucture would be unchanged. Color case hardening (to which you would assume the receiver was doubtless subjected) only affects the very outside of the case, that portion where the carbon molocules can attach; the interior remains soft

Gil what you are saying is correct, providing the innards were taken out and the heat couldn't reach them.

The one side with the slight reddish tint, that temperature was close to 1100F, not what I call low temperature.

If the stock had not been cutoff and then spliced, with all the care of his fine metal finishing, that gun would have been a decent buy. He wants $1,200.00 for the gun. If you did not need to replace the stock, then the proper case coloring expense would have been very cost effective. As it is you can not justify several hundred for the recoloring and then several hundred more for a new stock. You would end with over two grand in the gun and never get that much back out of it.

As a shooter is would have been a better buy before the torch. Big Ed1 strikes again.

Thanks Jon. I agree that this particular gun has too many problems. That is why I wanted to take the stock and any other issues out of the equation. I was only interested in what the torch could or would do to alter the metal and that particular gun gave a good visual example of one that had been torched.

Gil, I wasn't sure if "temper" was correct and apparently it isn't. I thought tempering hardened and made steel potentially more brittle. I thought what you described was annealing. I should have paid more attention in school.

Skip

Note in the ad the statement "Low Heat & Chemical". There is a process I have described here on this board on several occasions, taken directly from an Ithaca service manual, which they recommended for use on the Perazzis they once sold. These were I believe made from an alloy steel not suitable to regular case hardening but given a "Case Color" finish. The process consisted of heating to a temp hot enough to "Sizzle Water" (about 165°F) & then daubing &/or streaking with touch-up bluing on a Q-tip. This temp is less than boiling water & does absolutely no harm to the metal. The finish produced is actually rather well wearing & can be simply polished off if it doesn't suit. The question here is exactly what process did he use. If the colors were in fact produced my heating hot enough to produce "Temper" colors then they Do affect the original case. Yes Temper is the correct term. In heat treating the part is hardened to it's max hardness & then "Tempered (Drawn) back to desired hardness. In the old days, prior to a lot of sophisticated equipment this tempering was quite often done by "Color". The color is produced by oxidation at that temp, not by it's carburization, thus any "Temper" color produced has done so at the expense of hardness. Colors produced by "Spot" heating of a gun frame should in my opinion be avoided like the plague. The case of a case hardened/colored gun frame will normally be left at max hardness. Loss of color does not mean loss of hardness only that the oxidized layer has worn away.

Thus "Hardening" is the term which puts in the hardness & is done by heating a part above it's critical temp & quenching;

Tempering is a drawing of the max hardness back to a desired lower hardness & is done by re-heating a part to a predetermined temp which will obtain the desired hardness, but will always be less than that required for hardening.

Annealing is a process where the metal is heated to a high enough temp to remove all traces of the hardening & it will be allowed to cool slowly so no "Quenching" effect can occur to create a hardening effect.

There is no way one could, with a torch, heat an area hot enough to produce temper color without the case at that point being heated completely through, thus it will indeed affect the metallurgy of the case & it is being done non-uniformally. The original case was "Hardened" in a uniform manner, the random colors come from non-uniform oxidation, not from non-uniform hardening.

2-Piper has got it. No way would I consider buying a "recolored" gun like this unless it was going to be reharden by the proper methods. Bill

Thanks to all of you gentlemen, very much! I had heard many references here to the "torch master", but I never knew whom was being referenced. At the same time, in my quest for the perfect grouse-getter, Mr. Ed's ads caught my attention many times. Now I know...

Anyone wanting to know how to Colour Case Harden steel should read the following Forum:-

http://www.marlin-collectors.com/forum/viewtopic.php?f=21&t=3732This runs to fifteen pages and details one mans experiments on CC Hardening. I have found no better source of information on this subject anywhere.(I've been looking for several decades).

He details the ratio's of the charcoal and bone charcoal, the methodology and the temperatures and equipment used. It's well worth a read even if you never intend to CC harden yourself. It also removes a lot of the mystique and bulls**t of CC Hardening that abounds on other boards.

It's worth viewing, if for nothing more than just the pictures.

Harry

Harry,

Hi, Michael Petrov here, The late Oscar Gaddy wrote several articles in Double Gun Journal about case coloring. I don't remember the issues they are in but I suspect that some here will know.

Harry,

Fascinating reading. Where is the film available from?

Pete

Articles by Dr Gaddy: 'The Double Gun Journal' Vol 7, Issue 4 Winter 1996 and Vol 8, Issue 1 Spring 1997

Also "Color Case Hardening by Mr. John Hackley"

http://www.acgg.org/pub.html

Harry,

Hi, Michael Petrov here, The late Oscar Gaddy wrote several articles in Double Gun Journal about case coloring. I don't remember the issues they are in but I suspect that some here will know.

Hello Michael,

I have both of Oscar Gaddy's articles, but like most people who do/did, CC Hardening he doesn't give much away. The first part is available as a free download from the www. The second part is available on purchasing the magazine in which the article appeared. Both parts are subject to copywrite and although one part is freely available, the second part isn't, unless you shell out a few bucks to buy the magazine it appeared in.

Harry

Harry,

Fascinating reading. Where is the film available from?

Pete

Hello Pete,

All I know is what is quoted in the CC Hardening article. The DVD or VHS tape is available from the Secretary of the Marlin Collectors Club. Price about $25.00. Sorry I haven't the address of this gent.

Harry

Thanks Harry, I found it. If any one is interested, Harvey Frakes MFCA 217-585-3454 between 6pm & 10pm CST

Pete

A note of caution/interest: The marlin video is good, but many of us believe that it is not an accurate representation of how Marlin actually color cased their firearms. Jim (on the marlin board) tried to duplicate their process exactly as they showed it in the film, and after failure and experimentation, he also came to this conclusion. Its possible that the color case section was meant to leave Marlins competitors wondering how the hell they get such good colors. Gaddy's articles pretty much explain the entire process, in quite good detail, but its all about finding what works for you.

Channing,

Thanks for the heads up. I am more interested in other aspects of the film. Without getting into great deal, I feel that documentary film making was in it's infancy in the 1920's. In this I have a point of reference. I also have come to believe that company sponsored films of that era never revealed the full process.

I remember when Brownell's introduced their case color hardening kit. Oscar spent a great deal of time looking it over. I remember he pronounced it flawed. Stating something to the effect that the schedule was wrong.

Pete

Pete,

I agree very much with you that most of the films at that time never revealed any real factory secrets. How I wish they produced the show "How its made" back then. I agree very much with what Oscar said about Brownells "schedule" for case hardening. Give yourself a kick one time and call one of the reps at Brownells to see how much they know about color case hardening, and ask how many actions they have run

From experience, you can recolor an action at the Brownells prescribed 1450F, but you run a much higher risk of warpage, and I mean much higher!

So for those of you with more of a clue than I, if you were presented with an obviously torched gun at the right price:

1) Would you feel comfortable buying it if the price/gun justified a total annealing and re-case hardening? Any pitfalls in this that would be different from re-doing any other gun?

2) Assuming the seller would let you, could you easily test if the colors were the "low-heat/chemical" method with a bit of blue-remover? i.e. rub a q-tip with blue remover on colors--if they rub off it's blue; if they stay it's torched, or something to this effect?

Thanks,

Dave

Dave,

To answer your 1st question. I would not touch a torch job. Simply no way to tell if or how much damage was done.

About your second question. I have been playing with this method. I have learned that you can not apply several "chemicals" at once. They have to be applied in stages. The most difficult color to achieve is the bright blue that true case color can have. At least the cold blues I have tried so far are unable to achieve to that bright blue.

Pete

you can recolor an action at the Brownells prescribed 1450F, but you run a much higher risk of warpage, and I mean much higher!

To what temp do you recommend heating? If one goes much below this 1450°F they will drop out of the critical temperature range of the steel & hardening will not take place. This would of course reduce the possibility of warpage, but would also leave the action in a near annealed state. I personally would not want to give up that hard skin on one of my guns, even for perfect colors. When steel is quenched "Suddenly" from a point above it's critical temp, there will "Always" be a risk of warpage. So far I have not been willing to take that risk, so my guns remain un-re-colored.

I think the "right price" for a torched gun would be whatever it's worth to you as a wall hanger.

I would be interested in knowing for certain what this guy's chemical is, and just how much heat he applies.

To get the heat colors with a torch, you are getting into pretty high heats, and you don't need any chemicals, just a clean surface.

On the other hand, a guy I know has done some pretty reasonable looking faux color case, using IIRC clove oil, and light heat, just enough to heat up the oil on the surface.

I'll have to consult and see what his process is.

I've used the hot part/cold blue solution on some model engine parts that were to look case hardened, and it won't come out looking anything like that shotgun.

Cheers

Trev

I've been using the Brownells kit for the last couple years now at the University where I work. I have my students do bone and color case hardening on various parts of the steam engines that they build. We do use a modified crucible that reduces the exposure of air during the quench and the temperature we shoot for is about 1450. I have found over the course of hundreds of these parts that you do get better colors when you fall below the 1400 range, but much below that you won't get any appreciable hardening. Parts will warp during the quench unless they are blocked and I think this is critical to success when dealing with any firearm parts. If anyone wants to see the process I have a video that I shot of the process last semester and can posts samples of the parts that we do. It's not difficult to get good colors, but you do have to have a safe place to do this in.

Alex,

By all means, please do post the pictures. Have you uploaded the video to youtube

Pete

you can recolor an action at the Brownells prescribed 1450F, but you run a much higher risk of warpage, and I mean much higher!

To what temp do you recommend heating? If one goes much below this 1450°F they will drop out of the critical temperature range of the steel & hardening will not take place. This would of course reduce the possibility of warpage, but would also leave the action in a near annealed state. I personally would not want to give up that hard skin on one of my guns, even for perfect colors. When steel is quenched "Suddenly" from a point above it's critical temp, there will "Always" be a risk of warpage. So far I have not been willing to take that risk, so my guns remain un-re-colored.

Gaddy's temps seem to work quite well, and produce a good hard "skin" that passes the so called file test. 1350 max, quench at a stabilized 1250 or even 1100. Even the L. C. Smith engineers letter says 1600F, but a lot of those old timers did everything by eye. For example, the Parker letter between a retired Parker employee and a Remington guy who was having troubles recreating Parker like colors says that the retired Parker employee believed that his temps were too high at 1550, but he said that the coloring at Parker was all done by eye!

CM:

Let me pose a question & see if you have any input on this aspect. First it has been my understanding for the absorption of carbon & for hardening at the quench the steel has to be above it's critical temp. Since we are speaking here of re-hardening a steel previously carburized it is in efect already a high carbon steel on the surface, to the depth of the original case. However once the steel has been carburized the hardening effects are essentially those of any other carbon steel.

Quenching temps from an old (we are speaking of old techniques here) are as follows for various carbon steels;

.65-.80% C = 1450-1550°F

.80-.95% C = 1410-1460°F

.95-1.10% C = 1390-1430°F

1.10%+ C = 1380-1420°F

To obtain a "File Hardness" with a quench of 1250°F or lower certainly seems surprising to me. As the parts are already carburized & likely to a rather high % working in the extreme low end of the above ranges would seem plausible, but temps of 1350°F & down would seem questionable as to hardening.

Here's a few photos of test parts of 1018 mild steel that were polished to 320 in most cases.

Here are a couple photos of the loaded crucible and the system I have my students use when doing the quench. We have pretty much settled on a mix of 50/50 wood to bone charcoal though we have used other ratios in testing. Our temperature is around 1400-1450 in the furnace and probably around 1375-1400 at quench time.

Lastly here is the video showing the whole operation. We were using the smaller furnace that Brownells sells, but we also have the larger one as well. I personally don't like the crucible that Brownells sells as it doesn't offer a really convenient way to dump the parts without exposing them to air (though others mileage could and probably does vary in this respect). The system that I use that is shown in the video involves minimal contact with the outside air as the crucible is only about 1/8" above the surface of the water when it is slid off the cover plate.

[img]

http://smg.photobucket.com/albums/v733/44-henry/?action=view¤t=ColorCaseVideo.flv[/img]

Wonderful Alex! The best way to learn about color case hardening is through experimentation (not with customers guns tho, hehe

).

Miller, Carburization is a diffusion controlled process. The longer the action sits in the crucible, the greater the carbon penetration will be and the higher the carbon content. This was taken from one of the machinist manuals out there(mind you it is describing a molten salt bath)

Carbonnitriding starting with low carbon steel (SAE 1008):

1 hour @ 1425 to 1450°F results in a case .004" deep.

2 hours @ 1425 to 1450°F results in a case .006" deep.

3 hours @ 1425 to 1450°F results in a case .009" deep.

4 hours @ 1425 to 1450°F results in a case .011" deep.

1 hour @ 1600 to 1625°F results in a case .015" deep.

2 hours @ 1600 to 1625°F results in a case .021" deep.

3 hours @ 1600 to 1625°F results in a case .026" deep.

4 hours @ 1600 to 1625°F results in a case .030" deep.

For example, compare 1 hour at 1425 to 1 hour at 1600 and youll notice that your steel will absorb much more carbon than if you had run for an hour at 1425. The old low carbon steels that many, if not all manufacturers used to make their actions are essentially non-hardenable. They simply absorb carbon on the surface, leaving a thin "case" to protect the outside, and a soft inner core that allows shock absorption and stresses. A longer "soak" in a carbon-rich environment will yield just as good of hardness (and colors as) if you ran it for a shorter period of time at a higher temp.

CM;

Yes I understand that. I have been around case hardening, just not Color Hardening. In the machine shop where I worked we often actually did the carburization & the hardening in seperate operations. Other times all in one, depending upon circumstances. After that "Soak" though the "case" is no longer a Low Carbon Steel, but is now a High Carbon one. It now will respond to heat treating & this is what is done in the heating & quenching process. The core remains low carbon & does not respond to the quench to much extent & remains soft & ductile. Just the addition of carbon will of itself increase the hardness of the steel to some extent, but certainly not to that file hardness test unless heated & quenched. To obtain this result it must be above the critical temp for that steel & this would seem to drop but very little below 1400°F.

As you noted a 1hr soak at 1600° gives more penertration than a 4hr soak at 1425°. Drop much below that & my understanding is penertration will virtually halt. This too must be above that critical temp for effective penertration. From all data I have it would seem about 1350° would be about absolute bottom temp at the quench for effective hardening to take place.

In re-doing an action I am not certain it is necessary for any significant amount of penertration to take place. It would seem the carbon rich case is still there from the original carburization. Just enough surface penertrtion to provide the layer needed for the coloring, thus the higher temps (Or Long Times) necessary for deeper penertration would not be needed. As the part will have been annealed it will be necessary to re-harden & I can simply not see this taking place below 1350° bottom.

Alex,

Thank you. Very nicely done.

Pete

Miller,

Just say we are square here, Im not trying to say you dont know anything about heat treatment or color case hardening. I dont want to offend anyone here, but rather share what I can and hope that somebody might have a use for it. Secondly, Im not a metallurgist and dont play one on tv. What Im sharing is from trial and error, experimentation, and mostly from reading everything I can on color case hardening. I understand why youre not a fan of re coloring guns. Many folks dont like it because its so risky (but much less if your not shooting for 1450), and Im a firm believer that it shouldnt be done unless completely necessary (at least on doubles, I could care less about those guns with levers and one barrel ;)) Either way, if you ever get a chance, get together a group of guns and compare how hard they are. Ive noticed that all guns have different levels of hardness, which leads me to believe that reaching that critical temp is not necessary for re coloring. I think you will find that many of the trades leading case coloring providers will do the same (although they wont tell you). Ive owned guns that were sent to Turnbull, Menk, Classic Guns, and a new screw slot file cut through the thin case and right into the soft metal of the under-tangs on all of them. Another example, I had two L. C. Smiths that I was experimenting with. Prior to annealing, the one was rock hard. I couldnt even touch it with a course file on the back end of the tang! (this might explain the engineers letter stating 1600F for Smiths, but I still cant believe that). The other smith was much softer, and I could cut into with emery cloth after a few strokes. They were less than 1000 numbers apart, both in similar shootable condition. That is what leads me to believe that the hardness that is achieved by carburizing at or above critical temp is not necessary for re coloring.

Alex, I have some stripped, scrap actions I can send you to experiment with if youd like. They are old hammer gun actions and wont require an ffl, but I can even send you some that arent as old and we can go through an ffl. Give me a PM if you, or anyone else is interested.

CM,

I believe you are right that coloring can be done at low temps. After all, dark blue is reached at about 600°F and all the others are reached at lesser temps.

How else could Turnbull and others color a modern receiver made from 4140 or similar through hardening alloys? Most of them run around RC 30 or therabouts which corresponds to a tempering temp of about 1000°F. The heat treating procedure for 4140 is completely incompatible with conventional color case hardening of low carbon steel. Since all the colors can be produced well below that tempering temp., there is no problem heating and quenching as long as one does not exceed that temp. I think this is how the pros do it on a modern steel gun.

OB

I am by no means an expert in this area, but I do have a fair amount of experience with the bone and charcoal process. Some observations that I have made are that it is quite possible to get very good colors without actually getting the surface substantially hard. I did this last semester with a piece of 1095 that went in the quench at around 1250 and came out with beautiful colors, but it was soft enough to cut easily with a file. The problem is that if you are not hardening the surface you really aren't performing color case hardening. My research suggests that many older firearms had fairly superficial hardening, but they were still hardened. I have seen the site dealing with the Marlin restorer and find it very interesting, but I don't totally buy into his thoughts that these guns were quenched at these very low temperatures. I have found you can get very vivid colors at a temperature range that still hardens the surface, namely something over the critical temperature. At higher temperatures (over 1500 degrees) the colors start to diminish rapidly. I have never had a problem with warpage on the parts we have done, but if they are critical I make sure to block them appropriately. I cannot really imagine sending a rifle or shotgun action into the quench tank without some thought given to this possibility.

I am also a big fan of tempering the finished parts at 400 degrees for at least one hour following the quench. I think this helps in two ways, one it enhances the colors, and two, if by chance the part was a high carbon alloy it should help to prevent it breaking from excessive brittleness.

Will,

Thank you for your generous offer, but since I do most of my casehardening in a university lab with students I would not be able to work on firearms parts. Hopefully the information that I gather can be used by others in this area however.

Regards,

Alex Johnson

Im not exactly sure how much tempering the parts @ 400F for an hour does, for the most part it seems like all it really helps with is completely drying the action out. Id be hard pressed to believe that it actually reduced any residual stresses in the action(but maybe the small parts), simply because its not that hot. A good test would be to harden two parts, temper one at 400F, then see if there is a difference in hardness, breaking, flexing, etc. The L. C. Smith engineers letter says that they used to put the freshly quenched actions on top of the flipped over empty crucible to completely dry them out. Maybe this also serves as somewhat of a tempering process? Ive run test actions as hot as 1450 for two hours and quenched (exact same setup as Dr. Gaddy, sliding shutter system and all), and experienced minimal on-face warpage and minimal tang warpage, but, and heres the kicker, 2 out of ten had horrible (1/16" off face on one barrel) and horrible tang twisting and bending (down I believe). I highly doubt that any shop would be able to stay in business if their success rates were this poor.

Anyways, as for properly blocking, this is extremely difficult to do and very time consuming (most specifically for doubles). Its sounds easy, but here is what goes on, and this is prior to shielding!

On all double guns, you have a number of "areas" of concern when re coloring. The frame has two parts of concern, the "front" and "rear". The "font" area (water table and breech face) are rather large, making up the majority of any double guns action. (this is just box locks we're taking too, dont even get me started on sideplated guns). The "rear" of the action is the upper and lower tangs (very thin, and only attached to the frame in essentially one place each, and only attached to each by two screws usually).

Step one is assemble the stripped and polished gun, blocking the hammer slots, etc with perfectly fit steel blocks, as well as perfectly fit screw braces (steel tubing) to prevent any of the tang screws from bending, and it also helps to keep the tangs in proper alignment. This does not however prevent the tangs from bending down (or up) simultaneously (or twisting left or right! which is not good when trying to put an action back in the stock and all of a sudden you have 3" of drop, are now cast off, and have a rather large gap at either the top or bottom of the stocks head depending which way the action was quenched). So, you can try to brace the tangs all you want, but your still risking a lot of warpage, and that is true at any temperature.

Second is the "front" or actual frame. You have a large lug recess, which you can shape a piece of steel to nicely fit in. That does not however solve the issue of completely twisting the action at the breech, essentially destroying the gun because it is so off face. You can make up a jig, similar to the one Gaddy used (which can be noticed in his DGJ article. Its a massive block that sits in the lug, drilled and tapped for two screws to sit firmly against the face of the action), but this still does not necessarily put you in the clear because the breech can still twist in a number of ways away from the brace. That and you will lose colors where the brace touches the frame, something that you wont see on any of the "pros" jobs.

You could even go "overboard" (there is no such thing when it comes to color case hardening) and custom machine something to integrate the locking mechanism of the gun or the rib extension, but no one in the trade could afford to spend this much time on every gun that needs to be color cased. That can also be proven by examining for example, a Turnbull, Menk, or Classic Guns recolor, and you will see colors surrounding every part of the action (most interestingly the breech face and water table, ie, no jigs or braces used there). Now I could be wrong and maybe they do spend hours making and modifying jigs for all of the different types of actions just so they can run at critical temp and hopefully prevent warping, but I doubt it simply because they would lose their asses on every job. So, one is left wondering how they achieve those results without sacrificing colors on those areas, and the answer is exactly that of which we all mentioned, lower temps. Just as you said Alex, many of the old frames out there that many of us shoot hundreds, if not thousands of rounds through a year were probably superficially "hardened".

Here is a Sterlingworth I experiment with. Not exactly the right colors for a sterlingworth yet, so Ill re run it. Three runs so far (not counting the initial run it had at the factory) and NO warping, acceptable hardness, and the only thing Im not satisfied with is the colors yet.

400 degrees should be sufficient to temper the steel, 01 is commonly drawn to temperatures between 350-450 degrees and acheives a Rockwell hardness of around 60-63 at this range. I should clarify the time frame we use though. Since we typically are working with relatively small parts an hour at 400 is usually sufficient. Rule of thumb states that you should go one hour for each inch of maximum thickness of the part, I suppose a shotgun action would require 2-3 hours at that temp if you wanted to acheive the same effect. We have a Rockwell hardness testing machine in the lab, but casehardened surfaces are not that easy to check since the diamond just wants to break through the case into the softer section underneath. Comparison testing with a file definitely shows that the tempering operation softens the outer surface however. I still contend that its primary importance is for appearances though, it tends to bring out the colors and they always look better, in my opinion, after this operation.

You got nice colors on your action. I would suspect the plates you have help to contain the charcoal around the action during the quench, you get pretty much the same results with blocking. I've noticed, when using blocking, that the colors are generally better towards the side that the blocking plates are on. We use simliar methods for the parts we do in our lab, we have also had very good luck building fixtures that project out the bottom of the pack and enter the water first, I think this has the tendency to cause the water to be displaced and than it suddenly rushes in on the parts and creates very dramatic colors. Lots of possiblities with this process and it is always neat to see other peoples results.

I have absolutely no doubt whatsoever that the steel can be Colored at these lower tempertures. My only unresolved question at this time is "Is it desirable to re-color at the expense of the hardness". It has been pointed out & correctly so as far as I know, that at least most doubles which underwent proof did so "In the White". This would indicate they withstood proof without the benefit of the hardening. There are other considerations of course. Most seem to believe that from the beginning the primary purpose was for the Hardening & the coloring developed as a welcome, but secondary, factor. Consider for instance a 100+ yr old gun with ejectors which are set by being pushed in by rubbing down the breech face in closing. These 100 yrs & several thousands of times having been fired & closed would that breech face be in near so great condition had it not been "Glass Hard". I am not trying to belittle anyone elses choice or even sway opinion but trying to mull things over in my on mind & just perhaps throw out a little food for thought. As it stands right now though there are two things I don't want to happen. I don't want to send off one of my doubles & have

#1-Come back warped & with a poor fit

OR

#2-Have it come back significantly softer at the surface than it went off.

So far the risk of one or the other of these happening has just seemed to me to be too great, so I have decided to live with mine as they are.

Here is a Sterlingworth I experiment with. Not exactly the right colors for a sterlingworth yet, so Ill re run it. Three runs so far (not counting the initial run it had at the factory) and NO warping, acceptable hardness, and the only thing Im not satisfied with is the colors yet.

Will,

You should avoid having the wire touch the frame like aruond the lever and tang,..will spot your work and mess up your coverage

Your colours are good but better suited to English guns or an LC

very close to my picture below.

last two pictures are my Fox/Parker colours which I believe to be very close to original

CJ

Mr. Will, don't know if those colors are "right" for a Sterlingworth or not, but the colors look very nice. Hope you get your procedures worked out.

These are some stills captured from the Marlin DVD. Interesting bits of information.

Receivers are loaded by layers

Charcoal is spread between each layer

They take the crucible to the line of furnaces.

Notice the uncovered crucible on the floor

After heating it is removed from the furnace

And dumped directly into the barrel of running water

Steam from the dump.

The receivers are captured in a basket

They are taken out

The water is turned off

Pete

My thoughts are that if air touches the parts before the quench it will spoil the colors and this line of thinking is not supported by the process that they show here. I personally believe that this video was more for show more and did not represent the true process that Marlin used to color case there actions.

Alex,

I agree. They spend more time on the company executives and making the stocks than on anything else. I also found it interesting that they say, "One of the methods used" and that the parts are in the furnace for "3 to 4 hours".

I think that is true in general for these early documentaries. They never reveal their entire process. Still the glimpses they do provide are educational.

I encourage any one interested to purchase this DVD from the source mentioned above. I found the images of forging the actions very interesting.

Pete

If any air comes into contact with the metal you will get an ugly grey scale. PeteM is right (thank you much for posting the photos by the way). Many older films and probably many of todays modern documentaries do not reveal the entire process simply because it wouldnt benefit them. I havent seen the film, but from the looks of the pictures he has that crucible right over top of the (flowing?) water. Then it looks like he practically plunges it in the water while simultaneously turning over? This would surely prevent any air from contacting the steel during the quench, as there appears to be no drop distance between the crucible and the water like many of us are doing, but Im not certain it would produce optimum colors. There is also the possibility that he placed a flat lid on top of everything and then re-covered it with charcoal, but who knows.

Theres just something about that sh*t eatin grin on his face and how his bare hand is so close to the freshly remove 1000F+ crucible that still makes me wonder?

It doesn't look like there is any cover on that crucible at all, just the color of burning charcoal. There was a guy on the Marlin forum that tried to reproduce this stunt and had his receivers come out scaled and grey (exactly what you would expect).

If any air comes into contact with the metal you will get an ugly grey scale. PeteM is right (thank you much for posting the photos by the way). Many older films and probably many of todays modern documentaries do not reveal the entire process simply because it wouldnt benefit them. I havent seen the film, but from the looks of the pictures he has that crucible right over top of the (flowing?) water. Then it looks like he practically plunges it in the water while simultaneously turning over? This would surely prevent any air from contacting the steel during the quench, as there appears to be no drop distance between the crucible and the water like many of us are doing, but Im not certain it would produce optimum colors. There is also the possibility that he placed a flat lid on top of everything and then re-covered it with charcoal, but who knows.

Theres just something about that sh*t eatin grin on his face and how his bare hand is so close to the freshly remove 1000F+ crucible that still makes me wonder?

I have the software to "step frame by frame" through the film, which I did. He places an uncovered crucible in the furnace and you can see the black charcoal. He removes and carries it to the barrel with running water. He seemingly tips it directly into the water. As he does this, the internal of the crucible is not black, but a lighter grey tone than crucible. Is the charcoal glowing at this point?? Or did they switch crucibles during the filming and in fact there is a cover that fits internally.

From the film you get the impression that he immediately pulls the strainer from the water and handles the receivers. Movie magic? Perhaps. I have images of the damascus makers handling very hot metal bare handed, so I can not be sure.

What bothers me is they "fudge" the schedule by stating it as "three to four hours". I just don't buy that. I think they are hiding the particulars of the process.

On the whole, I should state that the original film must have been in very bad condition. I am pretty sure they taped the original playing on a screen. This tape was eventually converted to DVD. So it is a third generation image product by my guess. Definition and framing are degraded.

However, it is still worth watching. As it is the only historical record we have of an American gun making factory during this time period. I got a kick out of watching the workers going home at the end of the day.

Pete

It doesn't look like there is any cover on that crucible at all, just the color of burning charcoal. There was a guy on the Marlin forum that tried to reproduce this stunt and had his receivers come out scaled and grey (exactly what you would expect).

Ive spoken with Jim on the Marlin forum a number of times. What could be a possibility from the film is that there is indeed a cover sitting inside of the crucible, and that it is than covered with charcoal so we dont see it (why, I dont know, but it could be). I dont think that Jim plunged his crucible into the quench tank like the Marlin film photos show, and from seeing Jims pictures it looks like he loses the majority of his charcoal when he turns his crucible over (as his is rotating on a parallel plane with the quench tank), which is why his first parts showed zero color. Had he used an internal cap, much like the one he developed later to hold three actions at a time, then covered it with charcoal, there most likely would have been colors. An internal lid would prevent the charcoal from washing away as quickly, and especially if they practically dipped the crucible in the water.

3 to 4 hours is also believable, but obviously not very specific because Marlin doesnt want to give away all of their secrets. For example, Jim on the Marlin forum runs his actions for at least 2 hours at a specific temp, then drops to a lower temp for an additional hour. The total time the action sits in the furnace could be at least 3 hours simply becuase it takes time for the furnace to reduce in heat and then stabilize for an additional hour.

As for grabbing the actions out of the water as soon as they are quenched, that you can do because they cool instantly when quenched. As for the difference in color in crucibles, could it be possible to determine whether or not the frames were cut or edited through modern technology? Keep it coming boys, the board needs more topics like this!

I think as long as you get the parts to the quench as quickly as possible things will generally work out fine. I used several different techniques before settling on my present setup, others no doubt work as well, but I really doubt that any are more effective. I'm currently building a more elaborate quench tank that will allow me to monitor temperature and oxygen levels at the time of the quench and hopefully this will yield some more information on this subject.