I finally finished my stock bending fixture last week.

Another member here needed a Parker stock bent up and I needed to bend the Parker Repro 28g/.410 down.

So we got together for a little stock bending party today.

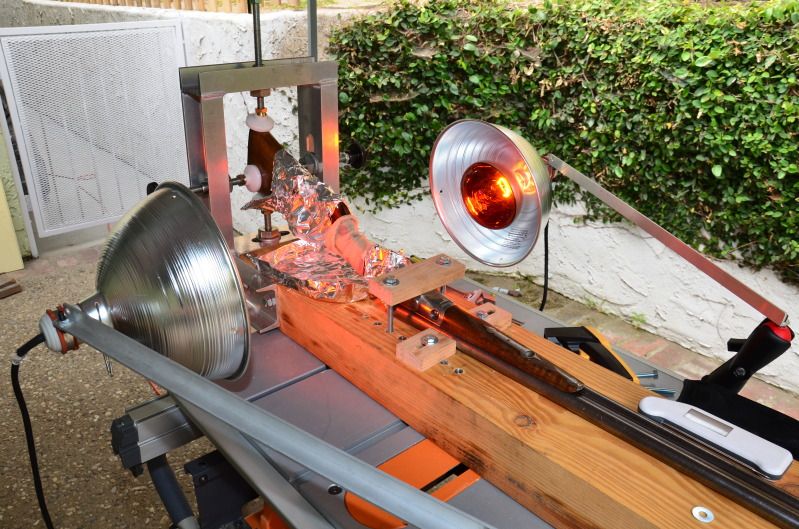

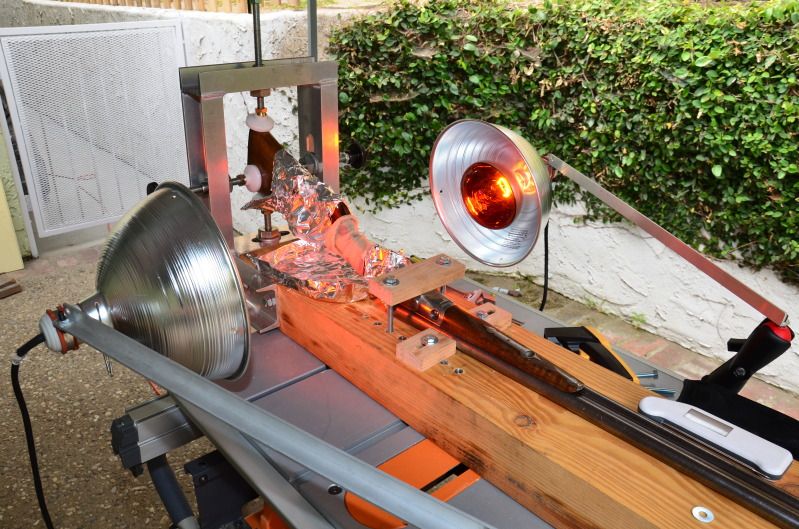

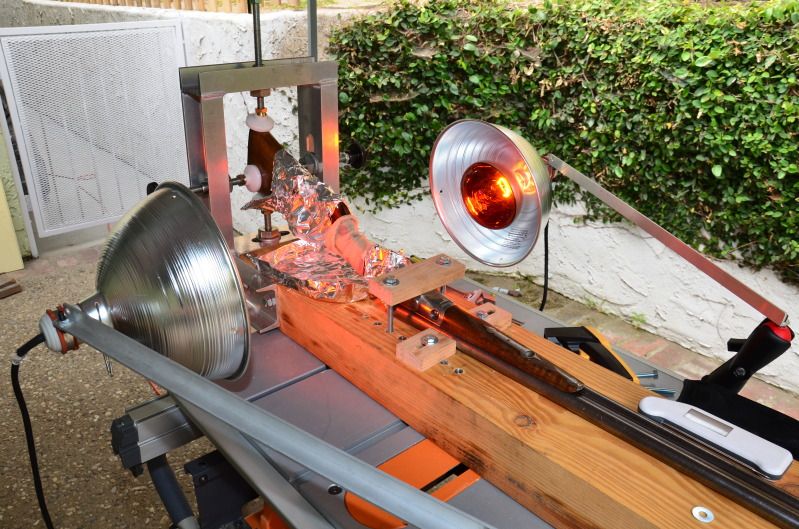

Here's the basic setup. We did the original Parker first. Triggerguard was removed. The gun had 3 1/4" of drop at the heel!

Once the gun was delicately clamped in the fixture, the wrist was wrapped with cotton rags and soaked in oil. It was continuously dowsed in oil at the wrist and foil protected what was not covered by the rags.

The first bend was fully a 1/2" after cooling and released. Very little springback. The gun had 2 3/4" drop at the heel now. We were so thrilled we didn't break the stock. The upper tang did look like it was digging into the stock a bit and we disassembled the gun and cleared the wood a bit to relieve the pressure. We then decided another 1/4" was necessary.

So, back in the fixture the gun went and we did another round on it. We also took out any cast and brought it to zero cast. Once cooled and released we were at 2 1/2" exactly. Fully 3/4" of bend in two bends! No cracks.

Next, my Repro was up. It's a straight grip stock.

In the fixture, clamped up.

I bent the stock 1/4" at the heel, down.

A friend had bent it down about 3/8" a year ago, but it came back to about 1/4" bend. It was still too high for me and I had shot it for over a year and still missed high consistantly unless I buried my cheek unnaturally. With the new drop, it feels very much like guns I shoot well. I might shoot it tomorrow to verify.

I'm pretty thrilled to have bent these two guns successfully.

Congrats! Some day I want to give it a try as well.

Amazing! It would scare the socks off me to try that..great job..

Impressive! Going in, I would think that very few would believe that you could bend a pistol gripped stock 3/4" up. Did the pitch change much?

Greg

We took enough drop out that pitch had to change. But it mounted to the shoulder well. Shooting it is the only proof in the puddin'. Im just amped about not breaking either stock.

Chuck, great post. Well done. If I may ask, when you bend up or down, do you get the impression that most of the bend takes place behind the tang, or did you notice? It would seem the upper and lower tangs would provide some stability to the wood between them and serve to hinder bending, or even promote "springing back".

What kind of oil did you use?

SRH

Stan

I think all the bend is behind the tangs.

Nice work indeed, well done, guys! How did the tangs turn out after a lot of adjustment?

A friend who is left handed bought a new Beretta 686. Why he did not put it up to his shoulder in the store, I do not know.

He can' shoot it as it is too "cast on" (?)

I can't shoot it either, I'm a lefty too.

How do you bend a shotgun stock with a bolt in it?

Very nice set up! Thanks for sharing.

Adam

curious - how long was the first one in the jig?

and how old is the wood

Mike,

Have faith! I'm a lefty and had my 686 bent to fit me by Reven's Restorations in Houston, TX some years ago. Everything moved as we wanted, and it has not sprung back. Aesthetics of the gun were not changed at all.

Jeff

curious - how long was the first one in the jig?

and how old is the wood

The heat was on for a total of 50 mins. After 10 mins we tried to move it. We added some pressure/displacement and let it set with the heat on for another 5-10 mins. It seemed to take a set of about half the amount we moved it. We added more pressure/displacement. Let is go 10 mins, checked the pressure by backing off the jacksrew, pushed by hand, set the jackscrew, etc. . Basically, all the amount of displacement was done by hand pressure, then held by the jackscrews, wait 10 mins, do it again. Then let the heat stay on after the last displacment for 10-15 mins, checked to see the springback was minimal, shut off the lamps, leave it wrapped in the oil soaked rags for at least 15 mins more, remove the rags, let it air cool to ambient, then remove clamps.

That first Parker is a damascus GH. I didn't ask the year of mfr, but if I were to guess, I'd say 1900-1910. So basically, 100 yr old stock, with another 50-100 yrs of growth as a tree.

Chuck:

Your set-up resembles mine in most every way, though yours is a bit more industrial in scale. I got my plans from Mike Orlen.

I have bent many of my stocks and those of my friends, and so far, no problems, knock on wood. I would not want to work on a gun that has had any repairs in the wrist, however.

I've bent both through-bolt and conventional box locks and side-locks.

I use common mineral oil, which doesn't smell as it heats.

Like you, I mask off the areas of wood with foil that I don't want to heat. This concentrates the heat on the wrist.

I keep my lamps about 10-11 inches away from the wood. I wrap the wrist with a long cotton strip about 2" wide. Every 5-10 minutes, I brush on enough oil to saturate the wrap.

I have an aluminum drip pan underneath the wrist to keep my work area as clean as possible.

Unfortunately I find that the oil will migrate into the action, so I strip each gun after I bend it to remove this excess. I haven't found a way to prevent this and don't know of a material that would block the flow of oil and not be affected by the heat.

This process really works for me, and I like the ability to custom fit my stocks.

Chuck did bending the stock crack the poly finish on your Reproduction?

Nice job and thanks for taking the time and trouble to photograph the process and post it here.

Best,

Mike

Mike,

No, but it did get tacky enough to leave the imprint of the rag on the small areas that aren't checkered in the wrist. I think a little rubbing with some compound will make it disappear.

Impressive.

I'd like to find someone in Maine both reliable and accurate (and not arm-and-a-leg expensive) to measure me, first, before I get stocks bent. I shoot lefty and my guns are set up for righties. Of course, that does make me concentrate extra hard on getting down on the stock and lined up properly.

Chuck:

Your set-up resembles mine in most every way, though yours is a bit more industrial in scale. I got my plans from Mike Orlen.

I have bent many of my stocks and those of my friends, and so far, no problems, knock on wood. I would not want to work on a gun that has had any repairs in the wrist, however.

I've bent both through-bolt and conventional box locks and side-locks.

I use common mineral oil, which doesn't smell as it heats.

Like you, I mask off the areas of wood with foil that I don't want to heat. This concentrates the heat on the wrist.

I keep my lamps about 10-11 inches away from the wood. I wrap the wrist with a long cotton strip about 2" wide. Every 5-10 minutes, I brush on enough oil to saturate the wrap.

I have an aluminum drip pan underneath the wrist to keep my work area as clean as possible.

Unfortunately I find that the oil will migrate into the action, so I strip each gun after I bend it to remove this excess. I haven't found a way to prevent this and don't know of a material that would block the flow of oil and not be affected by the heat.

This process really works for me, and I like the ability to custom fit my stocks.

M,

I'm using Phillips red 250w R40 bulbs. I put them 6" from the stock, but it was taking a long time to heat compared to what a friend showed me. So, I moved them to 5" and used that for all the work except the last 10-15 mins, I moved them to 6", where I had pushed the stock to the desired displacement and was holding it there under heat.

I also inserted a thermapen in the triggerguard tang screwhole, which was full of oil. I did this to get an idea of the temp inside. I got around 175F in the hole at the highest.

Jeff, we Canadians cannot ship our guns into the USA for gunsmith/stock work unless we have a Form 6 ATF and then we have to bring them in personally.

We have a British gunsmith in Ontario and he is backed up for over a year. My lefty friend with the new 686 will send his gun there when the season is over. We do have LH 680 series stocks for $900.00 each from the Vancouver Beretta importer.

I was looking for a used 682 12 ga sporter on Ellwood Epps (Ontario) website and I noticed one which looked like it had a left hand palm swell, on a pic of the top lever.I bought the gun, fantastic, a custom LH skeet stock, a beautiful piece of walnut.

Had to remove 1" from the 15" LOP, fits like a glove!

Mike

Great job Chuck.Seems to me if you bend a straight grip stock up,say 1/2 inch it would change the bottom line of the stock and cause a hump in it? Bobby

Bobby,

The old Parker was a pistol grip. My Reproduction was the straight stock and it got bent down.

Impressive there Chuck. You bending apparatus looks very similar to those I have seen in high priced gunsmith shops. I wish I knew how to do it....seems I'm constantly having stocks bent one way or the other. The guns I have had bent are all French walnut which apparently bends easily. I would like to know how your bending goes with American Black walnut. I have 2 Model 21 Win's with original stocks I would like to bend but have been too 'chicken' due to fear of breakage.

Buzz,

My Repro appears to be black or Claro. It's been bent twice, counting the 1/4" I bent it Satuday.

If I understand it correctly, wood has the fiberous material bonded by resins. The heat softens the resins, allowing the long fiberous material to slip during a bend. One side of the stock is in compression and the other side is in tension during a bend. Beyond that, I dunno what else might be going on in the wood during a bend. It stands to reason that various wood species would have different resin and fiber properties. Possibly one type of wood has different "melting" temperature vs another species of wood.

Chuck,I understand about bending your straight grip down ,but has anyone bent straight grip stock up,say 1/2 inch or more? Would the up bend mess up the bottom line of the stock? Bobby

Bobby,

Yes, the grip will look funny. It'll have a belly in the grip. I had a straight grip stocked AYA that had a 2 7/8" ish drop that I had a smith bend up to about 2 1/2". It looked a little funny if you looked at the side profile. I often thought about reshaping the bottom line and re-inletting the guard tang. But I sold it after I out grew it.

Chuck; welcome to the BRIGHT side of the moon! Started bending stocks in 1995. Your jig is impressive. Keep up the good work.

Dennis

Good work. I've bent about 30 stocks - a couple didn't work out so great. He's what I've found. Always check the flow of the grain through the wrist. The two times I've cracked a stock is because the grain came out the top and I was bending down. Think I would have learned after the first time but nooo. Also once a guy wanted some cast off on a stock that had some cast on. Once again I didn't notice the grain going out the SIDE of the stock. Good thing I'm fairly good at putting pins in the stock and glueing em back togeather. Bachelder steams the stocks - claims it works better. Wish I knew how to steam a stock. Like most things, just when you think you know what you're doing it'll reach up and bite you. Paul

Paul,

Thanks for the tips on the grain flow.

On whether or not steam or the lamp/oil method is better, I think it's all about getting the wood to the proper temp. Both ways will do it, IMO.

I recall bending some wood strips with steam. It worked well and quickly. There's steam and then there's STEAM. Steam can be anywhere from barely 200F to superheated. I dunno how to do superheated, but I would think it would need to be from boiling under pressure.

Mr. Chuck do you suppose I could borrow that jig,my daughter has her first date this weekend. I think I need to ask the boy a few questions.

I would think playing with a cigar cutter and your guns would be enough.

First date with my wife, a long, long time ago, when I picked her up I had to meet the parents. Her Dad just happened to be cleaning his guns when I arrived and we talked guns and hunting for about a half hour before she pried me away. He was surprised that a high school kid knew anything about guns, and she was pissed that I seemed to like him more than I liked her. No cigar cutter, though.

Shortly after meeting my future father-in-law, he invited me to go with him to Little John's Auction to buy guns. My girlfriend (now wife) was about half pissed. She said I was supposed to be polite, and that didn't involve going off on the weekend with him.

That weekend, I saw my future father-in-law buy guns by just setting there and not doing anything.

What a fantastic looking bending jig - simple and effective!

I had the stock on my Merkel 1620 bent by Griffin & Howe. In addition to returning the gun to me with a new crack in the stock, they also scorched the finish so that the wrist area is now much darker than the rest of the stock.

Since then, I have had many guns bent by Mike Orlen. He does a fantastic job, and the finish on the Orlen-bent guns looks to be completly unaffected by whatever heating process he uses.

Anyone know how G&H heats the wood for bending; anyone know what heating process Mike Orlen uses? Heated oil? Steam? Infra red? Heating tape? Hot air? Any others?

--shinbone

Mike apparently uses lamps and oil.

http://www.picturetrail.com/sfx/album/view/16314697I dunno about G&H.

Great examples of other bending jigs at the link. Thanks!

It looks like heat lamps and mineral oil soaked into a cotton wrap at the bend site are the way to go.

Just my opinion, but the big knobs on my fixture are unnecessary. Frankly, no knobs are needed. I just pushed the stock by hand as much as I was comfortable with, then turned the jackscrew to hold in place, repeat after some heat dwell time.

Smaller (than my 2") knobs would give a better feel if you elect to push the stock over by turning knobs instead of pushing by hand. Maybe some small plastic ball/knobs?

I heat mine quite a bit longer before bending. I like to let the stock heat all the way through before trying to bend. Usually wait from 30 to 45 minutes. It's probably from making damascus - with 6 to 9 layers of steel at start if only the outside layers are at welding temp and it's beat togeather the billet looks good but the inner layers aren't welded. You end up with a pile of sh**. So I like the inner wood also hot enough to bend so all the stress of bending is applied through out the wrist area. Good luck to all - Paul

Hello Chuck,

What a fantastic jig and corresponding result! Congratulations.

Here is a photo of a jig sent by Mr. Moe/Mike Orlen:

He uses canola oil; (more details in the Picturetrail posted above).

JC

Never tried bending myself but watching Jack Rowe do it years ago he said he always bent the wood by hand so he could "feel" the wood. Thought there was way too much risk of breakage if done mechanically. So he did it very similar to you, Chuck. He only used hot oil constantly poured over the stock--sorta messy and risked a fire (not nice).

Smaller (than my 2") knobs would give a better feel if you elect to push the stock over by turning knobs instead of pushing by hand. Maybe some small plastic ball/knobs?

Seems like bigger knobs would give you finer control because rotation at the perimeter would translate to less movement at the stock.

Personally, I am a fan of big knobs.

Paul,

When I was doing these, I was learning along the way. I would agree that trying to bend prior to heating thru is risky. I think that's why I simply pushed some deflection in the stock and then let it heat until it wouldn't springback when the pressure was released. That little test indicated that it had sufficiently heated thru. Of course that took another 10-15 mins beyond my initial 10-15 mins., which matches up with your experience of waiting 30 mins or so.

JC,

That's a nice clean, simple fixture. It's approximately the thickness of a friend's base for his fixture. Mine is overkill on the thickness. But I wanted to ensure I wasn't flexing the base, just the wrist of the stock.

Joe,

Thanks for the insight about how Jack Rowe did it. Comforting to get a hint that I have some instincts, even if Mike doesn't think I have shooting and hunting instincts.

Rp,

I think fine control is not needed. If it were, I'd use a finer thread pitch on the jackscrews. The "feel" of how much pressure is being applied is more important, IMO.

Before the terminology police catch you guys, I thought I should warn you that these things are not "jigs", they are "fixtures". I swear on my monoblocked gun.

I have been looking at bending fixtures over the years and have seen many different designs running the gamut from lightly-built (as exemplified by Mike Orlen's bending fixture shown in JayCee's post ) to heavier-built (as exemplified by Chuck H's fine looking bending fixure). All of these designs apparently work quite well. The simplicity of Chuck H's fixture has finally inspired me to make my own.

Since the stock bending process requires the wood to be softened to the point that it is easily moved (i.e., requiring much force beyond finger pressure to move the wood indicates that either it has not been sufficiently heated or you are at the limits of the wood's bending potential), I am wondering if a heavy duty fixture is functionally necessary? My thought is that if finger pressure or slightly more is sufficient to bend the wood, then as long as the fixture is straight, stable, and reasonably well constructed, a lightly-built fixture should work fine for stock bending purposes . . . ?

I ask because I don't have much in the way of wood or metal working tools, and making a heavy duty bending fixture similar to some that I have seen, as impressive as they are, is beyond my meager capabilties. However, a carefuly constructed, lightly-built stock bending fixture is something I can pull off, but if it won't reliably make good bends, I won't bother.

What do the stock benders say: is not much force required to bend a properly heated stock and thus a lightly-built fixture will function perfectly fine for stock bending?

TIA

--shinbone

I have a fixture that I built some years ago to Mike Orlen's pattern. The base is made of two pieces of 3/4" plywood glued together to give a nominal 1 1/2" thickness. The end piece that creates the bending force is made of 2x4 lumber. I use common bar clamps to provide the force. So far (about 10 years)it has held up very well for my hobby use. I use good quality cooking oil to soak the cotton cloth around the wrist, and heat it until it begins to smoke before trying to bend the stock. After bending, I leave the stock clamped in place until the cloth is cool to the touch before removing the clamp(s). I always get some spring back after the clamps are removed, but have never had any later change.European wood seems to bend with less force than American walnut.

Tom Martin - Thanks for the input. Chuck H's fixture looks really good to me, but Mike Orlen's fixture is more within my capabilties (it is the welded aluminum that I can't do).

A 2x4 jackscrew frame would be plenty sufficient, IMO.

I would still use a thick base since you don't want to flex the base at the same time you add pressure. How thick is thick enough to prevent flex? I dunno, but wood is cheap and I don't have to haul this around and up and down hills. I was trying to minimize the parts count and assembly tasks and still have the fundamental functions of the more complex fixtures out there.

Chuck H - makes sense to me. A 4x8 beam for the base is indeed super simple and super effective. And, a 4x8 wood beam is inexpensive for the rigidity you get.

BTW, how are the threaded inserts in the 4x8 held in place? Screwed into a predrilled hole? Epoxy?

They're just screwed into a drilled hole. I bought them at a woodworking supply house, Rockler. But I think I found some more at a hardware store. I layed out a hole pattern that I thought would cover a wide range of gun lengths and gauges.

Chuck, great post and excellent fixture. Great idea that the heat lamps are on a flexable fixture for adjusting the heat.

So, back in the fixture the gun went and we did another round on it. We also took out any cast and brought it to zero cast. Once cooled and released we were at 2 1/2" exactly. Fully 3/4" of bend in two bends! No cracks.

So, back in the fixture the gun went and we did another round on it. We also took out any cast and brought it to zero cast. Once cooled and released we were at 2 1/2" exactly. Fully 3/4" of bend in two bends! No cracks.