I saw a Perrazi o/u bbl with a bulge about a half inch past the chamber. The general opinion of the shooters standing around was that the bbls could not be repaired.

I am not so sure. What do you think?

danc

I saw a Perrazi o/u bbl with a bulge about a half inch past the chamber. The general opinion of the shooters standing around was that the bbls could not be repaired.

I am not so sure. What do you think?

danc

The shooters are right, once the metal is deformed the steel molecules are distorted and fractured......repairing that bulge is very dangerous that close to the chamber, a weak point will always exist.........it would be an accident waiting to happen........time for a new tube......

Doug:

This at least for me raises an interesting point. I know there are other factors besides distance from the chamber but at a certain point down the barrel can a bulge be safely repaired?

Jim

Totally agree with Doug. The metal has exceeded it's elastic limits and the molecules have stretched and can not be restored to their original position and strength. A slight bulge near the muzzle can often be repaired without too much future risk but even there it will always be the weak link.

I have tried it. Never again. You can't get to the part of the bulge that is under the ribs without removing them. Then you are getting into big money. If you decide to leave the part of the bulge under the ribs, you will still most likely pop the ribs loose while peening the bulge back into place, so you still have to relay them. There is always the chance there is a microscopic crack in the bulge that you can't see. Been there, seen that. Mine was discovered after removing the ribs.

It's a fool's game.

SRH

I have tried it. Never again. You can't get to the part of the bulge that is under the ribs without removing them. Then you are getting into big money. If you decide to leave the part of the bulge under the ribs, you will still most likely pop the ribs loose while peening the bulge back into place, so you still have to relay them. There is always the chance there is a microscopic crack in the bulge that you can't see. Been there, seen that. Mine was discovered after removing the ribs.

It's a fool's game.

SRH

I agree, junk. Should be thrown away.

Is it a mono block? I saw a K-80 have a new tube put in the mono block. NOT CHEAP but cheaper than a new barrel set.

bill

I hate to be a spoil sport here But I like to hear from someone who has direct information that a barrel failed due to a bulge

particularly if it was 12" or more ahead of the chamber.

Jim

I'd not advise repair, but am interested in the metallurgy of the question. As I understand stress-strain diagrams, after the metal yields, increased stress is required for further strain increases. That is, the metal is now stronger; often referred to as work hardening. I think, at least in theory, the bulged metal would be actually stronger than pre bulge. Anyone with a differing theory?

Again, I am most certainly not recommending repairing bulges near the chamber. Small bulges further down the tube and that don't extend under the ribs, different story.

DDa

I hate to be a spoil sport here But I like to hear from someone who has direct information that a barrel failed due to a bulge particularly if it was 12" or more ahead of the chamber. Lets see some proof that this actually happens.

Jim

I'd not advise repair, but am interested in the metallurgy of the question. As I understand stress-strain diagrams, after the metal yields, increased stress is required for further strain increases. That is, the metal is now stronger; often referred to as work hardening. I think, at least in theory....

I believe this has been brought up regularly. I wonder though, those stress strain charts fall off very rapidly. How can one determine if the bulge stopped on the safe side of the curve.

Maybe, if a bulged area survives the hammer back that's a bit of indication that it's okay? Seems like it's a technique that's regularly mentioned in the old literature. I'd think modern alloys may behave very differently.

The metal may be stronger from work hardening but now it's thinner as well. Would the two issues cancel each other out?

you all know how cheap some folks are...wont take a loss on anything.....makes you wonder how many bulges have bean repaired and the gun sold as if the barrel never was bulged....

Let me walk you through this, Jim. The particular barrel set I mentioned was a Philly 12 ga. Fox. There was a bad bulge in the right barrel about 10-12 inches back from the muzzle (30" barrels). After much time spent putting all the visible part of the bulge back in place, the top rib popped loose from the peening. Since the ribs had to be relaid now, I removed them, and decided to go ahead and remove the portion of the bulge between the barrels. That is when the crack was discovered.

Point here is, if the visible portion of the bulge had been successfully removed without the rib popping loose I would have never known the crack was hiding between the ribs. This could have had disastrous results with ribs flying off from the gas leakage through the crack. Microscopic bore inspection may have found the crack, but how many people have the equipment to do that?

Bulges can and do create stresses in the metal that exceeds the elastic limit. Maybe a very slight ring bulge could be repaired successfully. The trick is determining when the limit has been reached and when it hasn't.

SRH

In the warning Browning issues about not shooting steel in their classic Belgian-made guns (A-5, Superposed, Liege, Double Auto), they refer to the ring bulge that might result as a cosmetic issue. I've often wondered whether a ring bulge might pop the ribs, at which point it goes a good bit beyond "cosmetic". The only reference I can recall seeing about that possibility goes back to the early days of steel, when the wads didn't offer the same degree of protection as they do now. But I still wonder . . . Anyone ever hear of a ring bulge in the choke area popping the ribs??

The A5s had a bit of notoriety for ring bulges well before the days of steel, Larry. The tightly choked guns that were fed a steady diet of bigger pellets of lead shot often had bulged barrels.

I've never seen a rib pop on a bulged gun. That doesn't mean it couldn't happen. One of the regulars here (Don Moody?) astutely pointed out a few years past that pressure would be reduced as the load came to the bulge. Ahlman's Custom Gun has been saying the same thing as Browning for years, it is a cosmetic issue when the bulge is at the muzzle.

It would bug me if a good double had a bulge, however.

Best,

Ted

May and should are scary words when considering the close proximity to hands and eyes!

Anyone ever hear of a ring bulge in the choke area popping the ribs??

There was a KED-Grade Remington hammerless Double that my Father owned, and then passed on to his younger brother when he returned from WW-II. That gun survived decades of use with all manner of smokeless powder loads including plenty of Western Super-X and Federal Hi-Powers. In the early days of steel shot some of my cousins were shooting it goose hunting out in Western Minnesota, bulged the chokes and popped the ribs loose.

I've examined two of the quite rare Ithaca NID Magnum-Twelves with bulges at the start of the choke area, but neither had yet popped the ribs.

Stan:

You make an excellent point in your above post regarding hidden damage. After discovering this I would have strong reservations about continued use of this gun.

I also remember reading,and I believe it was here, regarding owners of damascus barreled guns finding minute holes right through their barrels due to inclusions that were present from the original forging process. I think they had been shooting these guns for years without ill effects.

I also have a friend who continued using a Winchester Model 12 after it was discovered to have a bulge in the barrel at about the halfway point. He used this gun that way for years and in fact may still be using it.

I know it's not a shotgun but I continued shooting a Colt OMM for quite some time with a barrel bulge until I finally located a replacement barrel.

As an aside: I suspect it would be interesting to run some strength tests with bulged barrels much as was done with damascus barrels.

Jim

I found this old thread about 'bulges.'

The subject gun I am considering purchasing has 3 bulges in the right barrel, according to seller. From the breech - 14", 15 1/2" and 17". The first two are just 'barely' noticeable acc. to seller. The 17" is more pronounced.

The subject gun is a graded gun not only with the barrel issue of bulges but needs wood work as well. Wood can be fixed. Dents can be raised. But will there always be an inherent problem in the bbls if the bulge is repaired?

He does not know bwt nor has the tools to measure. No inspection or return. As-is.

I don't want to waste $ but I do have another set of bbls that could possibly be fitted to subject gun.

Can bulges be fixed and barrels still be considered safe?

thanks for looking at above post.

Red, there are very skilled "smiths" who can usually repair dents to the point of "almost invisible." Metal science wise, dents of modest size and shape pose no particular issue; they are not going to grow or suddenly rupture. Yielded steel is "stronger" than the surrounding unyielded steel.

The bug in the ointment is the case of a bulge in the between-the-ribs area. Then, the barrels must be disassembled to repair - - - think $$$.

To a collector, once damaged always damaged. To a shooter, howz she shoot?

DDA

Part of my education is manufacturing engineering. Over the years I've been involved in countless metal forming operations and processes. One that seemed to jump into memory was explosive forming aft pressure bulkheads on commercial aircraft. We'd use a high explosive in water to squash and stretch a large piece of metal over a domed shaped form and flange it as well.

I could go on all night on examples of structural aircraft parts that are cold formed.

I'm with Don on this one. If the bulge is inspected and crack free, it is much stronger than before it was bulged. I say this because there is actual metallurgical industry standardized test data that can repeatedly substantiate this fact, not a gut feel. I can produce that test data, but my internet is down and I'm working from my cell iPad.

I also remember reading,and I believe it was here, regarding owners of damascus barreled guns finding minute holes right through their barrels due to inclusions that were present from the original forging process. I think they had been shooting these guns for years without ill effects.

Jim

Years ago, a friend and I were looking at a British 2" 12ga he was thinking about buying. Couldn't find any real issues other than some very small exterior pits (not holes) in the barrels, within 6" of the muzzle. We both thought the gun should be rejected on that basis. But after thinking about it a bit more . . . wait a minute! People shoot guns with REAL holes in the barrel out by the muzzle (ported barrels) all the time.

Major Sir Gerald Burrard in the second edition of

The Modern Shotgun (1948), Volume 3, The Gun and The Cartridge, “The Diagnosis of a Burst” discussed “Wave” Pressures and the etiology of multiple bulges pp. 364-375.

p. 365

When the explosive charge was placed entirely at one end of the closed vessel (discussing experiments by Paul Marie Eugène Vieille and published in

Etude des Pressions Ondulatoires in 1890) the gases given off naturally rushed forwards along the length of the vessel until the forward layer of gases was suddenly checked by the closed end. When this occurred the gases which were behind the extreme forward layer over-took this layer and began to pile up against it, with the result that the extreme forward layer was compressed with great violence. It was this compression of the extreme forward layer of gases which caused the high pressure…

p. 368

Since this wave pressure acts radially outwards the wall of the barrel is submitted to a very severe pressure all round its circumference, and if the pressure is sufficient to stress the barrel beyond the elastic limit of the steel a permanent bulge all round the bore is the result. Such a bulge is knows as a “Ring Bulge”...

p. 374

If the wave pressure was not sufficient to burst the barrel...the shot charge and obstruction will continue to travel along the bore under the influence of the expanding powder gases, but the wave pressure will be reflected backwards and will occur again at the extreme end of the cartridge-case. It will then rush forward once more (third wave) and may overtake the shot charge...in which case it will act again immediately behind the wads.

It is possible for the third wave pressure to be sufficiently violent to bulge the barrel some way ahead of the site of the first wave pressure, in which case one obstruction would be responsible for two ring bulges.

Radiograph of 2 bulges

I believe questions 1 through 9 should be

"What is the wall thickness at the area of the bulges?"

Red,

I am not sure about the barrel bulge, but I sure do not like the part about "No inspection or return. As-is."

That is always a red flag for me.

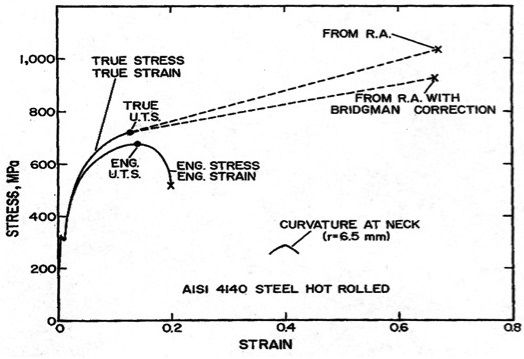

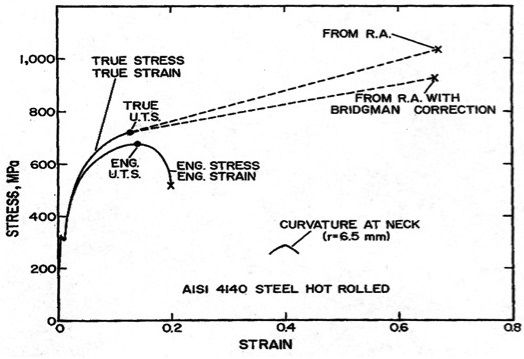

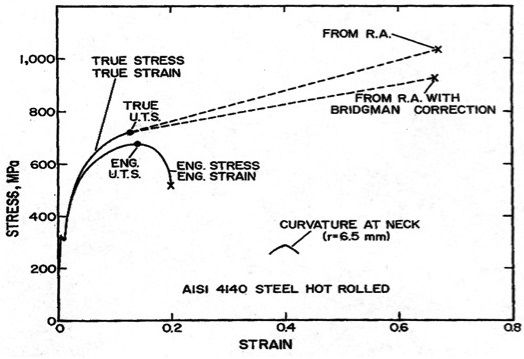

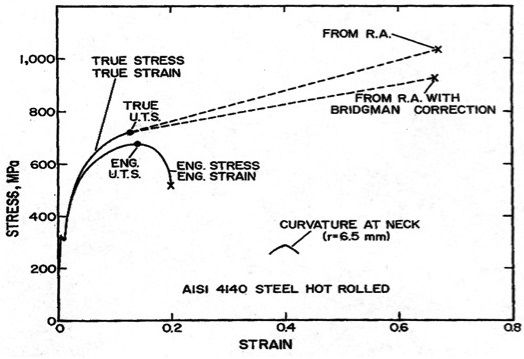

Here's a stress-strain curve with test vs corrected for section reduction true curve.

At around 310-330 MPa, there's a little whoop-de-do along the left side of the chart. That's where the elastic limit is reached and permanent deformation begins. As the test coupon stretches, it necks down in cross section. The lower curve simply shows the test data, without correction for necking. The upper curve is corrected for necking.

You can clearly see on both curves, once it (permanent deformation) begins, tensile strength increases and continues to increase until failure on the corrected curve.

There are are other effects to fatigue and fracture resistance, but the question on the table was strength.

So, as Drew pointed out, if you know the "new" wall thickness and the elongation, you can calculate the new strength of the tube.

....if you know the "new" wall thickness and the elongation, you can calculate the new strength of the tube.

Is there a good way to determine if the strain value of .2 is approached or exceeded? Also, once the maximum stress is achieved, would additional movement of the metal, bulge or dent repair, move that area farther to the right on the strain curve? Is it better to shoot a bulge as is?

....if you know the "new" wall thickness and the elongation, you can calculate the new strength of the tube.

Is there a good way to determine if the strain value of .2 is approached or exceeded? Also, once the maximum stress is achieved, would additional movement of the metal, bulge or dent repair, move that area farther to the right on the strain curve? Is it better to shoot a bulge as is?

Craig

The coupon fails at the UTS (ultimate tensile strength) point on the chart. To me, that appears to be in the area of 15-17% elongation.

Chuck - the engineering info you present is both spot on and quite correct. I would not, however, rely too much on it in the context we're talking about: a bulged barrel. The long and short of my reluctance (or objection) is that the information you're presenting is derived from carefully prepared laboratory tests run under controlled conditions. OTOH getting a gun to the stage of having a bulged barrel and now deciding whether to use it are not. They don't even rise to the level of a shadetree gunsmith tying a gun to a spare tire and firing it with a rope to see if it will blow up.

Other than illustrating ... something ... comparing a double with a bulged barrel to a Model 12 or other single-barrel is inapposite. There's a lot more going on with the double particularly, as noted above, under the ribs. Moreover, comparing this gun - with the bulge in the area of highest pressure 1/2 inch past the chamber - to any gun with a bulge near the muzzle - the low-pressure end - is likewise inapposite.

If the gun in question is to be used, it needs to be rebarrelled. Period. If that's too pricey, the guy intending to use it should price hand surgeons for comparison, then think again.

The subject gun I am considering purchasing has 3 bulges in the right barrel, according to seller. From the breech - 14", 15 1/2" and 17". The first two are just 'barely' noticeable acc. to seller. The 17" is more pronounced.

When I read this last addition to the thread my first thoughts were the wave pressures Drew Mentioned from Burrard. However in Burrard's notation each bulge was smaller as it got further down the barrel. In this case the l farthest (17") is the larger so it seems doubtful these all occurred with just one shot. I would doubt there is enough difference in wall thickness from 14" to 17" to allow a greater bulge at 17" with a lower pressure than at 14".

I found this old thread about 'bulges.'

The subject gun I am considering purchasing has 3 bulges in the right barrel, according to seller. From the breech - 14", 15 1/2" and 17". The first two are just 'barely' noticeable acc. to seller. The 17" is more pronounced.

The subject gun is a graded gun not only with the barrel issue of bulges but needs wood work as well. Wood can be fixed. Dents can be raised. But will there always be an inherent problem in the bbls if the bulge is repaired?

He does not know bwt nor has the tools to measure. No inspection or return. As-is.

I don't want to waste 2K but I do have another set of bbls that could possibly be fitted to subject gun.

Can bulges be fixed and barrels still be considered safe?

Don't drink the cool aid....

Chuck - the engineering info you present is both spot on and quite correct. I would not, however, rely too much on it in the context we're talking about: a bulged barrel. The long and short of my reluctance (or objection) is that the information you're presenting is derived from carefully prepared laboratory tests run under controlled conditions. OTOH getting a gun to the stage of having a bulged barrel and now deciding whether to use it are not. They don't even rise to the level of a shadetree gunsmith tying a gun to a spare tire and firing it with a rope to see if it will blow up.

Other than illustrating ... something ... comparing a double with a bulged barrel to a Model 12 or other single-barrel is inapposite. There's a lot more going on with the double particularly, as noted above, under the ribs. Moreover, comparing this gun - with the bulge in the area of highest pressure 1/2 inch past the chamber - to any gun with a bulge near the muzzle - the low-pressure end - is likewise inapposite.

If the gun in question is to be used, it needs to be rebarrelled. Period. If that's too pricey, the guy intending to use it should price hand surgeons for comparison, then think again.

Dave,

Engineering data is practical application data. There are qualifications for its use. I mentioned a principal qualification...being crack free. One I didn't mention was measurement for elongation. That data can provide good perspective on where the metal is on that stress-strain curve (how much strain has occurred). This is all factual data and people put their lives in the hands of this applied data when using engineered products every day.

However, if people don't have a good understanding of the data, it's qualifications, and confidence in applying such data, they shouldn't. In the case of a barrel bulge, a layperson may not have the knowledge to understand what is necessary to make the assessment of the actual condition of the metal or select and apply the appropriate data. , That's to be expected.

What surprises me, particularly on barrel bulges, is the perpetuation of heresy as fact, when actual engineering data is provided.

Subject shotgun is now in my possession. From sellers description and phone conversation, I was expecting B-U-L-G-E-S. Man was I glad to see what I would call pimples.

Seller was off on measurements. 1st - 13 1/2 from breech; 2nd - 15.25; 3rd - 18.5.

Measurement taken with my crude caliper:

Elongation - 1st - .159 ; 2nd - .185 ; 3rd - .195

Rise : 1st - .003 ; 2nd - .004 ; 3rd - .006

Location as if the bbl were on the receiver looking down the left tube: 1st - 7 o'clock ; 2nd - 7 o'clock ; 3rd - 5 o'clock.

These are not ring bulges, just pimples. Hopefully the ribs won't have to be stripped and relaid, but if they do, they do.

Anyone think the bbls are fixable?

If so, looking for smith recommendations.

Almost forgot. Barrels ring like the proverbial church bell.

If they are just pimples, I'd hammer them down with a plug underneath and shoot it.

Anyone who has read Greener's book about hammering down bulges until the gun passed proof would probably agree.

Of course, that's just me. I seem to be getting reckless as I age.

Oh no not me. I'm no smith and I don't pretend to be. I will leave this to the pros and gladly pay their fee.

Questions 1 through 9 remain "What is the wall thickness at the area of the bulges?" and without that information

no one can provide rational advice Red...but we are likely to do so anyway

This "pimple" on the outside

Looked like this on the inside

and may have been caused by the pilot while reaming the barrels.

Possibly your nearest barrel expert?

Kirk Merrington

Kerrville, TX

http://www.kirkmerrington.net/ 830-367-2937

Keith Hackleman (apprentice)

303-919-7376 cell

Dean Harris

Skeets Gun Shop

Tahlequah, OK

918- 456-4749

Thanks Dr. Drew. BWT forthcoming in a day or two. We recently moved, and it's still in storage. Mine is the type that you have to mount to a wall to get an accurate reading.

At the risk of opening a hornet's nest, in response to the OP's question those Perazzi bbls. might lend themselves to becoming a 'carrier barrel' for a set of tubes or even being chamber sleeved in the case of the affected barrel.

W/o seeing it and doing a bit of measuring one can't honestly evaluate it's 'salvageability' or 'repurposing' for either application/remedy. I do know of guns treated in both manners that continue to provide good service target shooting. Just saying its worth having a party who does such work evaluate it and go from there.

As to bulges removed from the chamber area, I have a 28ga. O/U that came back from a loan for someone to shoot dove w/in the late 60's that somehow got a bulge in it's lower bbl. roughly 6" back from the muzzle & in front of the forearm. The side ribs were not loosened. I have shot it that way since and still do and the gun has digested hundreds, if not a couple of thousand or more rounds since usually through that same bottom bbl. being fired first. Does it bother me? Of course, if I think about it and that it happened. It wasn't intentional, I know that. Am I concerned from a safety perspective? Not in the least. It's a 26" IM/F Charles Daly Superior grade Miroku and its still a delight to shoot dove with. Value was degraded, not the utility. 'Nuff said.

Very interesting discussion. I concur in that I would not want to mess with a bulge close to the chamber.

As to a bulge closer to the muzzle, after inspection with a knowledgeable person I would not be afraid. I had such a shotgun with twist barrels that had a bulge and a split about 5 inches from the muzzle on the bottom of the left barrel. With the concurrence of an individual with far more experience than I the the bulge was beaten down on a mandrel. I then took the barrelset to a local welder who told me to machine a piece of copper to fit snugly under the weld. He welded it and after dressing the weld I use the gun as my clays gun without a problem.

My point 1. The bulge was close to the muzzle and 2. I had a knowledgeable person look at it.