It drives Bro. Steve nuts when I talk about "scrolls",

LOL!! Yep! All of us modern damascus smiths are entirely focused on the four pointed “stars” in the pattern. My little brain just doesn’t understand counting scrolls.

To the original question regarding the inconsistent coloring, I would agree with Steve (usually a good idea ) that the mill mixed steel of different origin, and not purposefully.

Hmmm, I'm afraid I'm still in disagreement. My point all along has been that this coloring feature is anything but "inconsistent". In fact, that's been my major contention, that the coloring feature is consistent through all ribband sections. What is also not easily seen (due to lighting) is that the feature is present on the other tube as well. For me, it has never been an issue of intentionality.

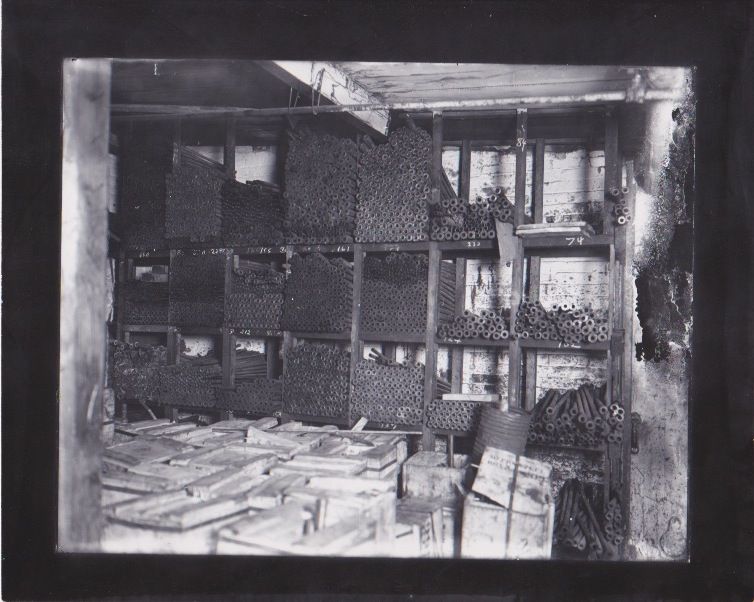

My reply about the coloring difference being a mix of different steels, was more intended to provide a reason for the colors, rather than an opinion on whether the difference was purposeful or not. I doubt that we can be assured of knowing the answer to the question of purposeful or accidental, unless contemporary writings about it can be found. That it is accidental is highly plausible though, I believe. I expect that the rolling mills had bins full of patterned rods. That a few rods may have remained in inventory for extended periods of time is possible. Then when finally sent to a barrel welder, it was delivered along with rods that were made later with steel of different alloy content. Too, I can envision stacks of rods in the corner of the barrel welder’s shop; with the same mixing of rods possible.

I can not conceive how damascus barrels with predictable designs including names could be done.

I am currently working on a post for this forum, which will explain how patterns with names in them are created. This post will be in answer to another thread on this forum, where I promised to provide this information. It’s taking me a while to pull the post together. I’m creating a bunch of illustrations and the accompanying text to describe the process. I’ve found that illustrating and describing what is happening inside a damascus rod as it is being twisted, to be similar in difficulty to describing what is going on inside a bowl of soup when you stir it. Putting all of this together is going quite well. Will post as soon as I have it completed.

What I'd like to know is if modern methods could produce damascus barrels as safe as steel why doesn't someone do it???...Geo

I am certain that damascus barrels can be made of modern steels! I have done it! The question for a manufacturer is; “is there a sufficient market for it?” Greener has been offering guns with sets of damascus barrel tubes. These barrels are made from old barrel tube forgings, supplied by Peter Dyson. So apparently, there is at least a small market for damascus barrels. Whether it is worth the expense of tooling up for an entirely new process to make these barrels, is uncertain. I met Ugo Beretta at the 2014 NRA Annual Convention. He asked me for my contact information so that he could have his people contact me. But as of yet, they have not. I would really like to sit down with a barrel manufacturer to discuss this possibility!

But the monotonous uniformity of a highly mechanized process would not be able to produce the unique works of art we admire today.

Honestly, I see no reason why a mechanized process would be destined to create monotonous uniformity. Knowing that it should be avoided, would only require steps in the process that were designed to create irregularity. Could be done.

I was able to catch a video of a seminar sponsored by a large blacksmith organization where a knife maker now passed on, Bill Fiorini, explains how he was approached by Holland and Holland to do a match pair of damascus shotgun tubes with the H&H name woven in along the entire length.

Maybe just talk but he made a few damascus barrels for the Bowen revolver folks that could contain their higher power magnum chamberings. He explain the H&H commission never went through because they wanted to make him jump through too many hoops. Too bad, could've been a great legacy gun for both parties.

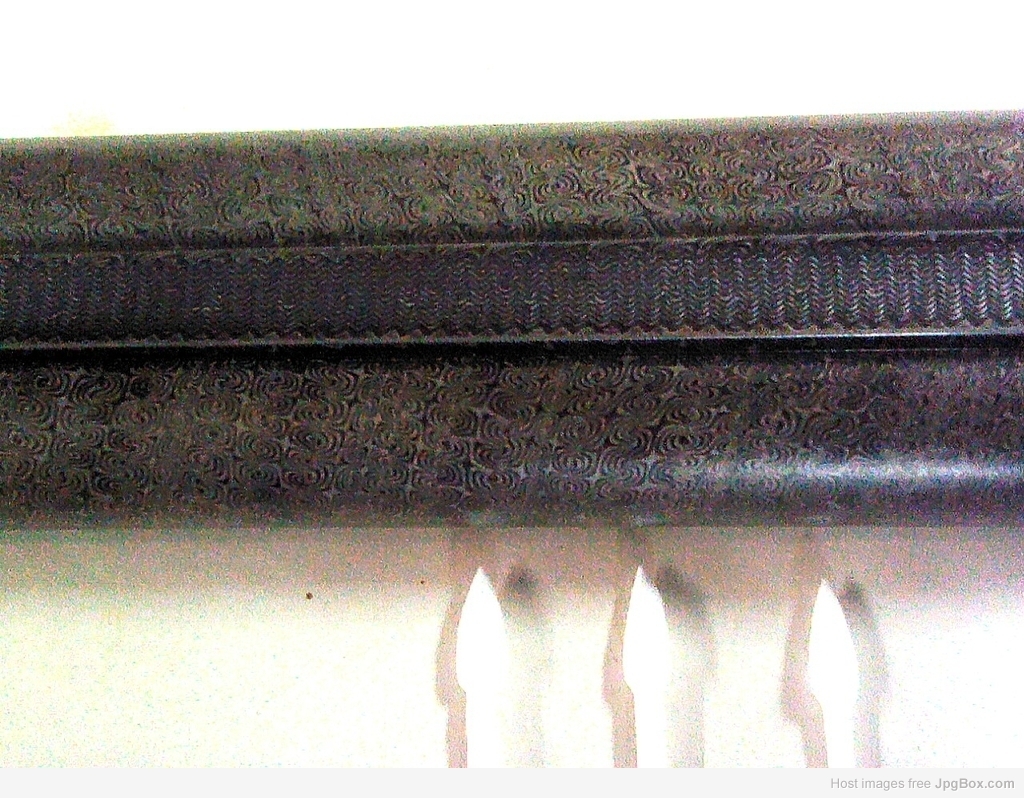

I knew Bill Fiorini. We discussed the making of damascus barrels quite a lot. I have some photos from one if his demonstrations. As far as I know, Fiorini never created Damascus barrels by the process of wrapping ribands around a mandrel to create a coil and then forge welding the coil into a solid tube. Bill made damascus barrels, by wrapping a damascus steel strip around a solid steel rod and then forge welding the entire mass together. The edges of the damascus strip were overlapped and scarf welded together, as the damascus material was at the same time being welded to the solid rod. The barrel’s bore is then drilled through the solid rod in the center of the welded assembly. There is absolutely no issue with this process, as it creates a very sound barrel tube. But, it is impossible to accurately recreate the old damascus barrel patterns by this method. My sole intention with making damascus barrels, was to recreate the patterns found in old barrels. Thus, I wrapped the damascus on a mandrel, as was done by the old barrel smiths. Below is a photo of Fiorini, doing one of his barrel welding demonstrations.

[img:left]

IMG_1969_1

IMG_1969_1 by

Steve Culver, on Flickr[/img]

I have a pictures of a couple of Fiorini’s barrels. Below is one of Bill's barrels. I heard about the H&H and Bowen dealings, but not from Fiorini. Bill and I never discussed it, so I don’t know much about what happened there. I’ve never seen photos of any completed functioning weapons built with Fiorini damascus barrels. Would love to see pics, if any exist.

[img:left]

3656981147_b233fddeed_o

3656981147_b233fddeed_o by

Steve Culver, on Flickr[/img]

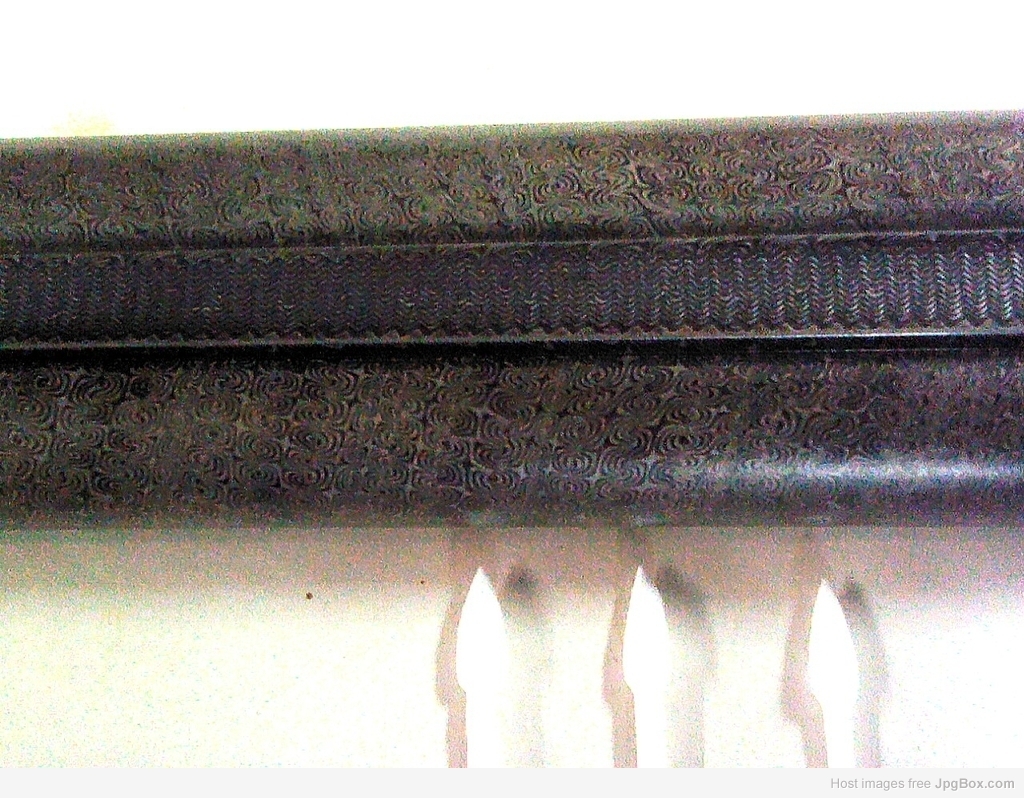

I am aware of at least one other blacksmith who utilized the same process as Fiorini. His name is Heinz Denig. Below are Denig pistol barrels. Something that I find objectionable about the damascus wrap over solid rod barrels, is the ring seen at the muzzle, created by the solid rod being exposed. Just my opinion……

[img:left]

Heinz Denig Barrels

Heinz Denig Barrels by

Steve Culver, on Flickr[/img]

Damasteel doesn't look like damascus and I don't think it is made the same way damascus was.

Damasteel is a powdered metal technology. I don’t know their exact process, but do understand a bit about how it is made. Essentially; two different steels, each in powdered form, are poured in layers. The powdered steels are then heated and put under pressure to forge weld them into a solid bar. Creating patterns in Damasteel can be done by many of the same manipulation processes that we use on pattern welded Damascus steel. I think some of the patterns available from Damasteel are created by disturbing the layers of powdered metals, before they are heated to fuse into a solid form. Kind of like sand painting in a jar.

Craig, I know that Steve Culver who posts here, has made a 2 inch damascus barrel for a pistol he built.

I’ve actually made two Damascus barrels. My first barrel was 3 ½ inches long, in two iron Crolle pattern. My second barrel was 4 ½ inches long, in Bernard pattern. Both of these barrels were built into functioning weapons.

[img:left]

Laffite's Revenge

Laffite's Revenge by

Steve Culver, on Flickr[/img]

[img:left]

Small Montage

Small Montage by

Steve Culver, on Flickr[/img]

Bro. Steve figured out the "Damascus Twist" lopin of the Batavia barrel

Ummm… Actually; I have realized that this billet arrangement isn’t quite correct. SORRY!! It’s very close, but not quite. I need to fix it and send you the proper stacking.