Jim,

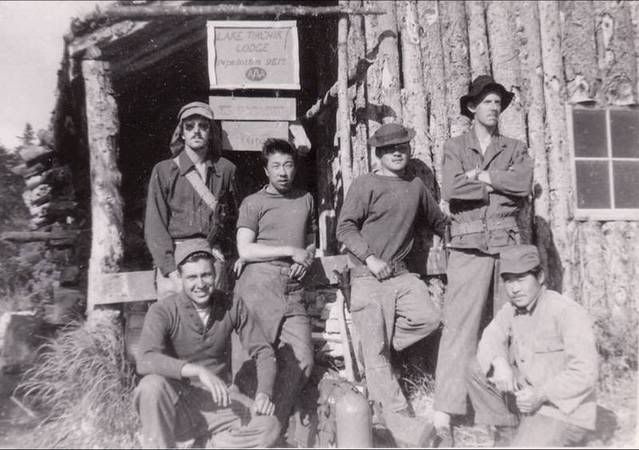

Lake Tikchik, Alaska, 1953ish, US Army Engineering Battalion Survey team

Dad enlisted in 1952 after graduating Univ of Missouri with a Mech E degree, hoping to be an infantryman and hero like the hometown guys in WWII. Big Green had different plans for him, instead he'd lead survey teams in Alaska that culminated in the 1954 USGS Maps. The US didn't have maps good enough for warfighting in Alaska, which was very close the bad guys. That hand painted sign says Lake Tikchik Lodge, population: 9 EM. The asians in the picture were nissei japanese.

They'd spend 5 months a year in the boonies surveying, with darn little contact with the outside besides the resupply drops. Dress code went out the window quickly, notice the white bucks below.

I believe it was one of the greatest times of Dad's life. He was in two helo crashes, one after a giant condor attacked the little Bell they were in, and another in the fog. Encounters with all kinds of wildlife and amusing stories about typical Army SNAFUs; They needed toilet paper, and instead got a pallet: half .22 ammo and half dried prunes. Dad had just bought Mr. Ruger's neat little .22 pistol and could make alcohol from just about anything. They wiped with whatever.

Dad was a great engineer, a dedicated milsurp gun collector, and a decent home gunsmith for the time. He traveled the world designing drill rigs for Ingersoll Rand, Sullair and Tamrock. He was an excellent story teller and had some fine tales to tell. I think you'd have liked him.

Looks like a Colt to me.