Illustrated Fox Disassembly (~260 kb) - 01/07/08 05:41 AM

This is my procedure for removing the stock from a Fox.

A magnetic parts tray is a convenient way to keep track of stuff. A screwdriver (I prefer a magnetic stubby for this work) with the proper size hollow gound bits is absolutely essential and Brownells is an excellent source. I use a 0.120” brass drift punch/alignment pin and mine came from Brownells.

1) I remove the forend and barrels and push the lever to the right to expose the top tang screw and select the proper size bit….usually a 340-2 (.340” wide and .020” thick), sometimes a 340-3. It’s important that the bit fit deeply but snugly and fill the slot from side to side.

2) Applying pressure on the lever to the right and pushing down with a screwdriver on the trip pin in the rib extension recess allows me to ease the lever back to the center position. Note the trip pin has 2 flat sides at right angles...upon reassembly, one flat faces to the rear and the other towards the right barrel.

3) Assuming the hammers were cocked before the barrels were removed, I now press a wooden block against the breech face and pull the triggers to decock the action.

4) I next flip the gun over and, with the proper size bit, remove the wood screw securing the triggerguard. The guard unscrews with 4-5 turns, exposing the rear tang screw, but I don’t remove it yet..

5) I like to remove the forward floorplate screw first, again with a 340-3 on my SW’s, a 340-2 on my early A grade.

6) I like to use a 1/16” drill bit, screwed in by hand to capture the little trip spring in the bottom of the hole. I find this is safer than turning the action over and letting it fall out…..and roll under the workbench.

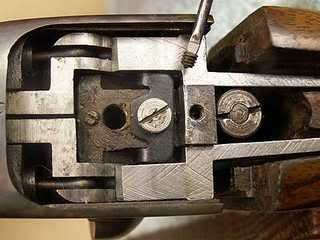

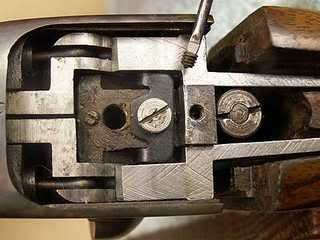

7) Now I turn the gun over, force the lever to the right to relieve pressure on the trip pin, and push it out the bottom with a small screwdriver (drift punch, etc). It could be left in, but that would mean the lever would have to stay to the right and there’s a risk of forgetting the pin and losing it accidentally. Best to have it safe and secure in the magnetic dish.

8) Now the rear tang screw can be removed and the floorplate lifted off, primary by wiggling and pulling up on the triggers. It may be necessary to tap around the action with a nylon or wooden mallet, but the stock will be loose at this time and great care must be taken not to chip the sharp edges of the inletting. From now until it’s off and clear of the action, the stock is very vulnerable to damage.

9) There are 2 tiny set screws locking the axles in place. We want to remove the rearmost, sear axle screw. It’s possible to just loosen it, but we’d only leave it engaged by a thread or two and there’s a risk of losing it…..best take it out and secure it. It’s very tiny and/or often buggered, so you may have to file a cheap jeweler’s driver to fit, as I did. For stock removal and action cleaning, only the rear sear axle needs to be removed. For a complete teardown, the forward screw and hammer axle would be removed later.

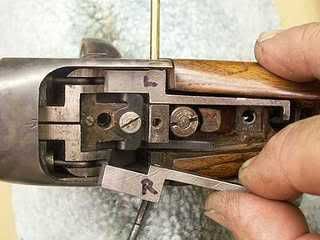

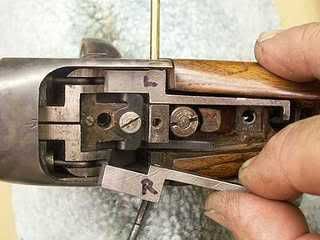

10) It’s not hard to figure out how to reinstall the sears, but for the first timer it’s helpful to letter them in their proper orientation. Here the .120” brass punch has drifted out the sear axle and been withdrawn halfway to release the right sear. It’s under very slight spring pressure…..nothing goes flying.

11) With both sears removed the stock can be tipped down and free. I find it a bit easier to go on and off if the safety is “ON” to the rear.

12) Lastly, the auto-safety rod, if present, is removed from it’s tunnel in the stock. I have a collection of them since I always remove them permanently, preferring a manual safety. One is headless, one has a very slight head and one has a head like a nail. They all measure 1.750 – 1.800” and I imagine that’s important, though I haven’t fiddled with them.

13) Assemble in reverse.

A magnetic parts tray is a convenient way to keep track of stuff. A screwdriver (I prefer a magnetic stubby for this work) with the proper size hollow gound bits is absolutely essential and Brownells is an excellent source. I use a 0.120” brass drift punch/alignment pin and mine came from Brownells.

1) I remove the forend and barrels and push the lever to the right to expose the top tang screw and select the proper size bit….usually a 340-2 (.340” wide and .020” thick), sometimes a 340-3. It’s important that the bit fit deeply but snugly and fill the slot from side to side.

2) Applying pressure on the lever to the right and pushing down with a screwdriver on the trip pin in the rib extension recess allows me to ease the lever back to the center position. Note the trip pin has 2 flat sides at right angles...upon reassembly, one flat faces to the rear and the other towards the right barrel.

3) Assuming the hammers were cocked before the barrels were removed, I now press a wooden block against the breech face and pull the triggers to decock the action.

4) I next flip the gun over and, with the proper size bit, remove the wood screw securing the triggerguard. The guard unscrews with 4-5 turns, exposing the rear tang screw, but I don’t remove it yet..

5) I like to remove the forward floorplate screw first, again with a 340-3 on my SW’s, a 340-2 on my early A grade.

6) I like to use a 1/16” drill bit, screwed in by hand to capture the little trip spring in the bottom of the hole. I find this is safer than turning the action over and letting it fall out…..and roll under the workbench.

7) Now I turn the gun over, force the lever to the right to relieve pressure on the trip pin, and push it out the bottom with a small screwdriver (drift punch, etc). It could be left in, but that would mean the lever would have to stay to the right and there’s a risk of forgetting the pin and losing it accidentally. Best to have it safe and secure in the magnetic dish.

8) Now the rear tang screw can be removed and the floorplate lifted off, primary by wiggling and pulling up on the triggers. It may be necessary to tap around the action with a nylon or wooden mallet, but the stock will be loose at this time and great care must be taken not to chip the sharp edges of the inletting. From now until it’s off and clear of the action, the stock is very vulnerable to damage.

9) There are 2 tiny set screws locking the axles in place. We want to remove the rearmost, sear axle screw. It’s possible to just loosen it, but we’d only leave it engaged by a thread or two and there’s a risk of losing it…..best take it out and secure it. It’s very tiny and/or often buggered, so you may have to file a cheap jeweler’s driver to fit, as I did. For stock removal and action cleaning, only the rear sear axle needs to be removed. For a complete teardown, the forward screw and hammer axle would be removed later.

10) It’s not hard to figure out how to reinstall the sears, but for the first timer it’s helpful to letter them in their proper orientation. Here the .120” brass punch has drifted out the sear axle and been withdrawn halfway to release the right sear. It’s under very slight spring pressure…..nothing goes flying.

11) With both sears removed the stock can be tipped down and free. I find it a bit easier to go on and off if the safety is “ON” to the rear.

12) Lastly, the auto-safety rod, if present, is removed from it’s tunnel in the stock. I have a collection of them since I always remove them permanently, preferring a manual safety. One is headless, one has a very slight head and one has a head like a nail. They all measure 1.750 – 1.800” and I imagine that’s important, though I haven’t fiddled with them.

13) Assemble in reverse.