What is a source to buy claw mount rings to file for my DR?

I want to go go head and file my own claw mount scope rings. I have the time and believe I am more than up to the challenge.

[img]h[/img]

Old colonel,

See below: "First Try But I Cheated a Little..."

With kind regards,

Jani

Old Colonel: The rear spring loaded mount is in my opinion the easiest, but should be done last, matching it to the finished height of the front. When you have smoked it in vertically, smoke it again and let the spring loaded shim make a mark in the smoke. File (cut) the groove (slightly uphill) beginning above the mark and polish it to a final fit. Whatever you do, don't guess about what is going on in fitting things--let the smoke tell you the truth. Even clean out the carbon from the groove every time so that it doesn't give you a false sense of "tight."

The front one, to me is the stinker. There has to be somewhat of a fulcrum effect after the tilt-entry angle as the rear of the claw sits down in the groove. If there is not, the contact GOES AWAY. As the rear sits down, the top front of the claw has to elevate into firm contact with the angle at the inside top of the groove, at least that is how it was on mine. I suppose one could make it shorter than the opening of the groove and shove it forward, letting the rear mount hold it tight, but I wanted the rear of the claw (though rounded at the bottom corner) to brace against the rear of the groove, staying tight of its own accord. Don't be disappointed if you have to make one over. Get a good set of files (the ones used to make hardened dies are the best), down to the Swiss sizes, and good luck!

I think that Oscar nailed the source, if you want it all low, and do not desire an under tunnel for the iron sights.

Clearly, I had no tutor, and there may be vastly better methods to keep everything nice and squared up...I welcome all hind-sight over on the other thread... Steve

BTW, I like the metal checkering on your mounts, and am fascinated by the screw-on rear mount. I have not seen one exactly like it. Lovely...Steve

Actually, when fitting the rear, it is the "slider" that should be fitted to the hook(groove)which should be cut so that it stands "proud"of the bottom of the base.By filing the bottom of the"slider",it forces the base down.Filing the "groove",may leave movement in the assy.BTW, it can't be fitted hard against the rear of the base,since the feet swing in an arc when the scope is removed.The front base comes with the plate(when new)and they are forced together under great force by hydraulics, and they have the same radius on the plate and the hooks(they know what it is).If a hand made base is fitted to an old plate, the plate should be removed from the rifle,so it can be forced onto the hooks.If this is not done,handmade rings can give good service as long at they are used as fixed mounts and not removed often.

Mike

Mike: Thanks, and wow everyone, keep them coming. I want to get it right and if it saves some time, even better. I don't personally want to remove the bases as that would mean resoldering them back in and rebluing, but if that is what it takes, it explains the high cost from some quarters. JJ Perodeux at Champlin Arms charges $400 for just the top ones, I don't see him resoldering and bluing for that price, but don't know. I also did not see a radius inside the front hook base; it appeared to be a slope, a straight angle. I could stand corrected if the radius was too slight to be observed, I did not make a cast or such thing. I sure invite Oskar to chime in and tell us a bit about his methods. If I had remembered his post, I might have contacted him, but then he expressed a strong desire to stay in retirement concerning such work!

Concerning the slider, I purposely created the groove proud of the bottom of the slider, then carefully worked it down, polishing it down to a final tight fit. I think it accomplished the same thing, though if I had flubbed it, I would have had to start everything over. I have seen such sliders with a groove worn on the bottom as well, by rubbing the hooks over the years, and they could have used a refreshing. But you might be right in that the slider was thought to be the replaceable part, and expendable. One's idea of expendable being somewhat tempered by the fact that the slider was probably of non-standard custom size and might be a pain as well to replace. (or could be built back up by spray plasma procedure?) Still, if one thinned the slider too much, it would all be loose and have to be redone or replaced. I just worked it from the other direction...Steve

Old Colonel, I apologize if I should just keep my mouth shut and listen to others with lots of experience. I do want to learn! Didn't mean to redirect the thread...Steve

But you might be right in that the slider was thought to be the replaceable part, and expendable.

The main reason for the front sliding part is the lateral adjust for the reticle of older european rifle scope, the other adjusting was a screw in the rear upper part of mouts. So the skilled gunsmith could tap the sliding part temporary away and file these front upper parts hooks the way as

Der Ami described. And when ready just install the sliding part back to itīs place.

If the mounts have lateral or windage adjustment(mit support), it would be in the rear mount and above the hooks. This adjustment is done by opposing screws and is not filed at all. The "grooves' on the slider are not from wear at all, they are from filing to fit the rear mounts.If there has been too much filing on the slider( hooks too high,should be about the width of a scribe line "proud"),it can be easily replaced.BTY,the leading edge of the slider can have a small angle to get it started, but the fitting should be level, not as a wedge(recoil would wedge everything together too tightly).It is realitively easy to fit the slider to the hooks, but pretty hard to fit the hooks to the slider, and there is a good chance of getting the hooks too low.Working the hooks reguires "blind filing", but filing the slider doesn't.The way to do it is to remove it,and with a pick, remove the springs that act on it.Put the slider back in(leave the springs out and one "thumbpiece").Put the mount in and push the slider forward(a brass drift and small hammer is helpful).With whatever spotting agent you use on the hooks or slider, the area to be filed will be obvious when the slider is removed.Once it gets started,it shouldn't be necessary to use any spoting compound,bright wear spots should be enough.Using the drift and small hammer insures all the "slack" is taken up in fitting. In fitting the front hooks( this is not usually done for new mounts,as the plate comes already forcefit to the hooks)it is easier to drift the plate out of the base( out-left to right,in right to left)and fit it onto the hooks.Then you can see the underside and can get a better idea of the profile required.By locking the ring down in the vise,a drift can be used to force the plate onto the hooks. This will leave wear marks on the hooks,showing where filing is needed.Spotting agent can be used to start.Final fiting should be done with worn 320 grit cloth backed by a file.Final fit should take a fair amount of force to install the plate.It will feel easier with the scope is instaled, as it makes a pretty long lever. Do I have everyone confused yet?

Mike

Not confused on the front hooks--it would be great to have the front base out after all, and be able to "peen" or otherwise force the final tightness from below (but a little intimidating to unsolder it, as it is not just dovetailed in by a tight fit.) Thanks for taking the time!

As to the rear mount, am I visualing you removing only the narrow "groove" of metal which contacts each claw and not milling flat the center portion of the underside? Understand not filing the lateral adjustment! Wouldn't dream of it. Had one Sauer with a worm screw adjustment (no opposing screws) which turned much too easily for my tastes. Wished I knew how to tighten it up at the time. The adjustment was always moving mysteriously at the worst possible time. Once again, thanks for the input, Mike...Steve

Old Colonel: Have you looked at the offerings by Ziegler ZP mounts, Betewe, and Clawmounts.com? Steve

Steve,

I didn't understand you had that type base,most use the plate, dovetailed to a base.My advice wouldn't work in your case.

New England Custom Guns,has mount parts from Recknagle and maybe Ernst Apel Wuerzburg (EAW).EAW has a system to change from claw mounts to swing mounts, while keeping the ability to return to the original.This does away with the problem of having to select a scope with straight tube or very high mounts.These companys have websites.

Mike

If anything had to be resoldered, it would definitely also be a temptation to go swing mount for many reasons! As to the configuration in question yet another reason for me to learn to post pictures, and avoid confusion...Steve

I haven't learned how either."old Dog etc."

Mike

I am enjoying this thread on claw mounts as I have been working on adding some rings to a drilling with claw bases for awhile now. I purchased a front ring base and plate and rear blank base from NECG. I removed the original front plate (it was dove tailed into the plate) and installed the new plate and base. I wanted to use the original front plate but after talking to NECG installing a new plate and mount seemed like the reasonable way to go. My next task was to file out the new blank rear mount base to the original rear plate. I used small files and smoke and tried to be patient and take my time. I have it pretty well fitted now and I am almost to the point of fitting the slider to a notch in the rear claw. My rear plate is a little different as there is only one slot. Basically I have three legs or claws instead of four which may make this process easier? So, now that I am about to create the notch for the slider this discussion came about (good timing) and I have read it and reread it several times and I want to make sure I understand Mike's comments as I'd like to get this done right. But I am not sure I completely understand what Mike is saying. So, I have some questions and possibly some photos if I can get the photos to post.

1. my rear plate has screws to hold the plate on but some drillings have a rear plate with no screws. Were the rear plates with no screws soldered onto the barrels? Did they normally use a soft (low temp) solder to do this? Can the soldered on plate be removed without damaging the solder on the ribs? If so how would this be done?

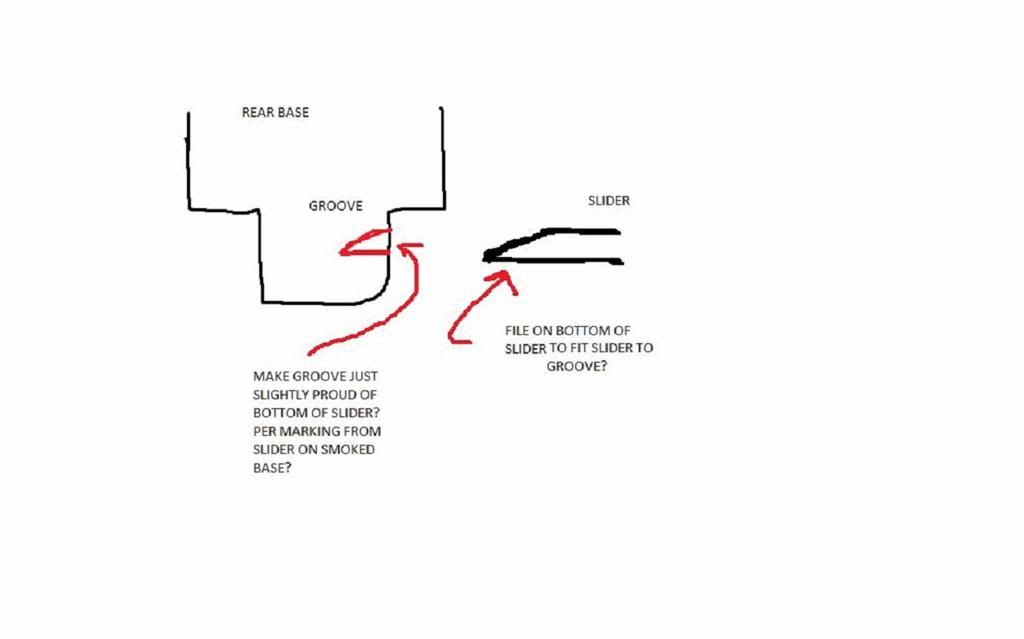

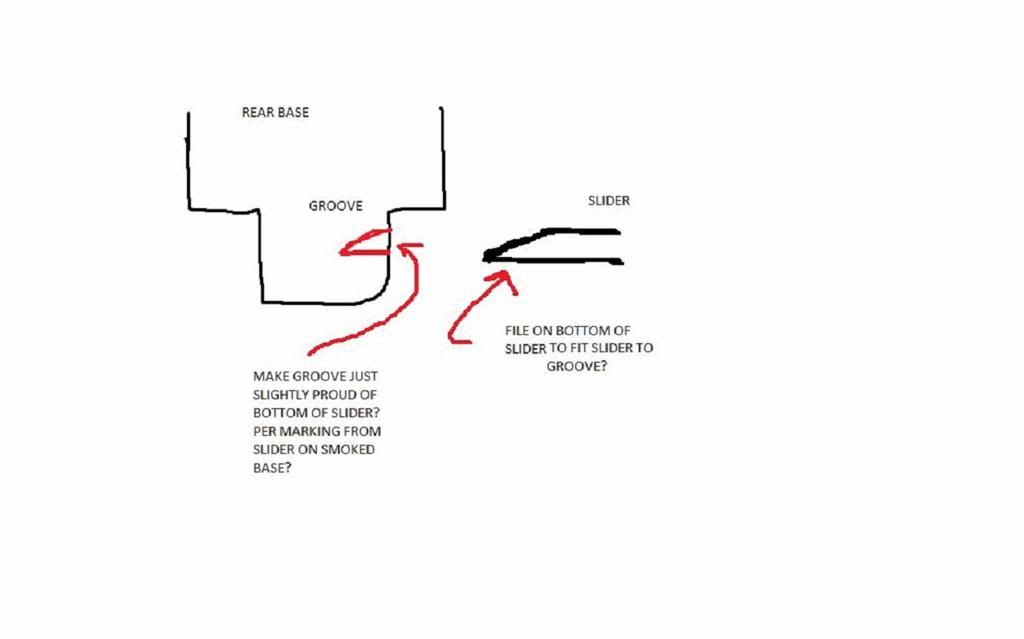

2. If I am understanding Mike correctly in his earlier post would the process for installing the new rear claw(s) be to first fit the new claws to the slot(s) in the original base using smoke and files. Then use the slider to mark where the notch or groove would be made in the rear claws? Make this notch very slightly proud or higher than the mark from the slider? Then file the bottom of the slider until it fits into the notch in the claws? I was just a little confused on this last step and wanted to make sure I understood the process. It seems like you have to use the slider to know or mark where to file the groove in the claw. Once the bottom of the groove is completed and left just slightly higher or proud of the slider do you then file the bottom of the slider to fit the groove?

Again, I appreciate the helpful information on this topic and it is great timing for me.

Thanks, Ron

Here are some photos of the claw mounts and bases on my Merkel drilling and the work in progress. Hope this works.

First a sketch of my understanding of the process.

A photo of a drilling with a rear base that I believe is soldered on?? No screws so I guess it was soldered?

Some photos of the claw mounts I am working on.

A photo of the rear claw mounted on a 1" diameter steel bar used for fitting in the claw to the rear slot in the plate.

I think the sketch came out small so let me try again.

Ron, your screw on mount looks similar in many ways to that on Old Colonel's DR, with the exception of one claw. The claw is wider. Make use of all the room below and to the sides to keep it as beefy as you can. The depression beneath the base is curved, ostensibly to allow the front of the claw to be beveled in order to snap down past the beveled front of the slider. I personally don't like that feature in that I like to keep the hook as stout as possible (having had one fail when shooting a slug--bending one hook to the breaking point), but that is just me. There is so often so precious little metal left beneath the slider in the first place! And some gunsmiths even want that to be specially hardened. I believe Kreighoff made the single hook rear mounts for a while. POLISH to final fit, or polishing at all may remove more metal than you want. Take as long as you need to get it perfect. Tight is everything. Good luck...Steve

rfrankhauser,

I stood shoulder to shoulder with Fred Schagelmilch(sp)in Walter Grass's shop and watched him mount many scopes, mounting a couple of my own with a really lot of help from him and Walter. We used new parts, but I will try to walk you through their process, but accounting for your parts as best I can.But first, I will answer your question about the rear base w/o screws.Yes,they are soldered on. Walter and Fred used soft solder paste(solder and flux mixed in paste form)and filled with wire solder if needed.The original rib had to be cut out,Fred used a small saw and a capeing chisel to reach the areas between the barrels.Once cut, the ribs were wired up with blocks to keep them from comming loose.Once the rib sections were removed(BTW don't forget to remove the rod that activates the rear sight)the bases were fitted by scraping and spotting( they used Prussian Blue mixed with common oil and a flux brush, but any spotting agent will work).The bases were soldered in(slider and springs removed from rear base),and "skim milled" on top surfaces, including dovetail,to make them parallel to the barrel flats.After this is where your work comes in.The plate is fitted to the hooks when it is delivered, but since they were forced together, sometimes a little bit of metal is rolled up on the side of the hooks, which is cleaned off with a scraper.The front ring is installed (to make it easier,assume split rings) and the scope is installed in the front ring(center and level the reticle) and boresighted with an adjustable block( a small steel block with a screw in the top)under the scope at the rear base, held together with a chord.Boresighting at a hundred yards or so, by adjusting the screw up or down will show the needed height of the rear ring, from the bottom of the scope to the top of the base.This height is transfered to the ring with a caliper or other convienent way, and the feet are are extended to this scribed line by milling(or fileing in your case).The needed length of the rear feet(foot, in your case)is found by measuring with a caliper, milled to length, and filed to fit the approximate contour of the barrels.Once it is fitted to the base,the feet are marked to locate the slot for the slider,by scribing a line through the slot in the base(at the bottom of the slot).The slot in the feet is milled with a specially shaped cutter(can be carefully done with saw and files), so that the scribe line remains(barely).Then the slider is fit to the feet as described before.Your drawing seems to show a wedge shape, unless you have already done it, don't file the slider to a wedge, make it more or less parallel, with a break on the leading edge to start it into the slot. It should be fit pretty"hard" to prevent "play".The rear of the feet are filed on an angle to provide a "cam" to move the slider backward when installing the scope.Then everything is polished,top of bases engraved, and blued. To make it simple, this description was for bases w/o windage, the differences for bases w/windage adjustment would be pretty much self evident. I know this is confusing, if you have a question, I or someone else will answer it.

Mike

Ron, I have used a magnifying glass and still can't read what is below you illustration, but I think I get your gist.

Another try of my original sketch. I think this one is readable.

Is this a better sketch of how the location of the groove in the rear foot is determined?

And a sketch of my understanding of how the height of the rear claw mount ring is determined. Reading the text and sketching out a drawing sometimes helps me grasp the process better.

Mike, I've reread your post several times and I believe I understand most of it. I really appreciate how much time you took to answer my questions. I still have a couple of questions though.

In your post you say the bases were skim milled to be parallel with the barrel flats. Just to make sure does this mean that the front base with dove tail installed is skim milled to be parallel with barrel flats? and the rear base is also installed and skim milled. Skim milling is only to make the top surfaces parallel to the barrel flats but does not necessarily make the front and rear bases the same level and I assume the wouldn't very often be at the same height?

A second question. When you determine the length of the feet or foot on the rear ring do you basically just use a depth gauge and insert the gauge in the slot until it hits the bottom of the base or the top of the barrels? Then the feet are contoured to the shape of the barrel and made to the length of the above measurement?

And last for now, I am still a little unclear how you would actually scribe the line on the rear foot to determine the location of the slot for the slider. I understand the concept but am unclear how you actually do this? Do you remove the slider and springs and somehow insert a scribe from the rear of the base? or do you remove the slider and springs and come in from the side of the base to scribe the line? Or could you just leave the slider installed and use the slider itself with some smoke and let the slider mark the line to be scribed? I'm just not quite getting how this is actually done.

Again, thanks for all your help. There just isn't much information out there on how this is done and while I don't mind learning through trial and error it can be frustrating. Sure helps to get some good information on how it is done.

Ron

Steve, Thanks for the tips and suggestions. I am pretty sure I'll have a scope mount completed before too long but whether or not it will return to zero when removed and installed will be the real test for me.

I'd really like to see a close up photo of your completed rings if you have a chance to post one.

Thanks,

Ron

Ron,

I believe your bases have already been "skim"milled to level them(when orig. installed).It would be very difficult to scrape them in level, and milling them level is easy(they have to be close though, or milling removes too much).The bases are not often the same height, just as you thought;this is where the boresighting/measuring distance to base comes in.The chord isn't used to tie the scope to the adjustable block,rather it is to fasten the scope to the rifle, with the block trapped between( you need to be able to remove the block to adjust it).

The depth gage at the end of the caliper(or any other type)is used to measure from the top of the base to the top of the barrels,through the opening for the foot.Measure to the lowest spot,mill the foot to this length, then contour it to approximately fit the barrels.The foot should't bear on the barrels, though, or it may interfere with other fitting.

Once the foot is fitup(the slider and springs should have been removed for this operation),you can reach in through the slots on the side and scribe a line on each side with a sharp scriber.If you don't have one, it can be easily made.

If you can find a gun with clawmounts that have been mounted in Germany, or by a Germany trained gunsmith, inspecting it closely can help you a lot, to see how deep to make the slot in the foot for the slider,the angles, etc.The trouble with learning through trial and error is that the cost of the error can be pretty high, if you have to buy new parts.Let us know how it works out, and as always, I'll do what I can to help.

Mike

When I made mine I just set two quarter inch screw driver bits on my bases and taped(electricians tape so it would stretch) the scope to the barrels. I made sure the scope was optically centered and used a laser bore sighter and shimmed the rear of the scope to determine the difference in height between the front and rear base.

Interestingly my bevel on the slider is just the opposite, wedging the rear base tighter as it moves forward. My rear legs are shorter than the depth of the base, which makes sense to me as a slightest bit dirt in the base would not allow it to return to zero.

oskar,

The slider should be parallel where it locks into the foot, the slight bevel on top is to help cam the slider back, when installing the scope(the corner on the bottom should also be "broken" a little to get it started).The reason for fitting the slider to the feet(with the notch being a little proud)is to take all "play" out.As far as the lazer boresighter is concerned, I have no experience with them, If it works, use it. When working on a drilling or BBF, a conventional bore sighter can't be used w/o some kind of adapter.I'm not putting down your work at all, I admire anyone with the guts and ability to mount one. I'm just reporting what I learned at the hands of a master,some of which I know seems counterintuitive.

Mike

Ron,

I believe your bases have already been "skim"milled to level them(when orig. installed).It would be very difficult to scrape them in level, and milling them level is easy(they have to be close though, or milling removes too much).The bases are not often the same height, just as you thought;this is where the boresighting/measuring distance to base comes in.The chord isn't used to tie the scope to the adjustable block,rather it is to fasten the scope to the rifle, with the block trapped between( you need to be able to remove the block to adjust it).

The depth gage at the end of the caliper(or any other type)is used to measure from the top of the base to the top of the barrels,through the opening for the foot.Measure to the lowest spot,mill the foot to this length, then contour it to approximately fit the barrels.The foot should't bear on the barrels, though, or it may interfere with other fitting.

Once the foot is fitup(the slider and springs should have been removed for this operation),you can reach in through the slots on the side and scribe a line on each side with a sharp scriber.If you don't have one, it can be easily made.

If you can find a gun with clawmounts that have been mounted in Germany, or by a Germany trained gunsmith, inspecting it closely can help you a lot, to see how deep to make the slot in the foot for the slider,the angles, etc.The trouble with learning through trial and error is that the cost of the error can be pretty high, if you have to buy new parts.Let us know how it works out, and as always, I'll do what I can to help.

Mike

Mike, I believe most of what you said in your last messages makes sense to me. But I just want to clarify a couple of points to make sure. When the bases are skim milled is the front base skim milled with or without the dove tail plate installed? Or is just the dove tail plate (base) that is skim milled? In my case this was already done when orig installed but just trying to make sure in case I do another set sometime? Just not quite clear on the skim milling and trying to understand it.

The clarification on the chord makes sense. It is simply used to temporarily attach the scope (in the rear portion) to the barrels so the gun can be boresighted by actually firing the gun at 100 yrds. I may be wrong but I assume this is to get the scope close to correct so that the scope has enough room to adjust it internally using the elevation and windage dials. The scope and gun need to be boresighted (and installed close to correct) to ensure that you do not run out of internal adjustment on the scope dials. On my install I thought about this but pretty much just used a long straight edge to make sure the scope was installed relatively level with the barrels and looked appropriate. I also did some testing using a bore sighter (not laser) and it looked like I was going to have the scope close enough that I could complete the scope adjustment using the scope dials and not run out of movement room. Also, I felt it was important to have the feet on the front ring installed fairly parallel to the front base if that makes sense. In other words I wanted the front feet to sit parallel to the front base and this limited how much I could raise or lower the scope in the back. I could see how you could make minor adjustments though.

A very helpful tip on the feet and what they should bear on. I have been trying to make the rear foot bear on the barrels as well as the bottom of the ring and I even thought that possibly the foot bearing on the barrels was the most important bearing. So, I will now shoot for having the feet close to the barrels but have the rear scope ring bear on the rear scope base. In other words the flat area that surrounds the foot will bear on the rear base. I assume that having this done well helps to ensure that the scope returns to zero each time it is removed. And as Oskar noted if the foot is bearing on the barrels all it would take is a little dirt to get in the slot and then this might affect the return to zero.

I'd like to examine a completed set of claw mount scope rings that were done correctly and I can see how that would help. At this point I have only been able to examine photos I have found on the internet of claw rings and bases. I'll keep looking for better examples though.

And yes, trial and error can get expensive. I have ruined at least (2) sets of front and rear bases but have been able to use my TIG welder to add metal in the appropriate places and put them back in service (and start over).

Again thanks to everyone for this very helpful thread. Makes the learning process easier and when I get a set of rings "good enough" I'll post a photo. Might be awhile yet though!

Ron

Ron, you are correct about having the flat area that surrounds the foot down onto the rear base--that is very important. The feet touching the barrels on the bottom is unwanted, BUT get it as close as possible, including contouring, so that it is as strong as possible in resisting upward prying forces during recoil, which is where I have seen one fail.

Concerning the fitting of the slide, here is my concern: human perfection not being a possibility, design it so that, as Mike said, it pushes down on the foot. How? Well, since there are tolerances involved in the fit of the slide to the horizontal slot it moves in, something has to "take up the slack" of those tolerances, or it isn't really tight. I decided it should be the slot that forms the top of the feet. I angled it EVER so slightly "uphill". As it is polished, it gets really tight just as the slide is coming to the end of its travel. In fact you have to give it a push to complete the travel. A wear mark on the side of the rear base conveniently showed when the slide had maxed out. It may be that Mike's plan is better on several accounts and less risky. But if I were to adjust the slide instead of the slot for the feet, I would STILL adjust it at a slight, slight angle in order to tighten up. A perfectly level slot is probably not a possibility. Even if it were, the area that sits down on the top of the base probably wouldn't be perfectly leveled, and that would tilt things. The slide is microscopically loose in its groove. And even if everything were perfect, by the time you got the slide to move over the perfectly level foot, it would not be pushing down with much force AND WOULD NOT GET TIGHTER, since it would slide across at a straight angle. I want it to unmistakably get tight! 25-30% of the claw mounts I have inspected on guns were a bit loose if you took the time to lift up on the rear of the scope--they moved! And of course to varying degrees. The first I saw was on a spankin' new Mannlicher Schonauer back in the late sixties. The person who had shelled out a wad of bills for those days was so upset he returned it to the vendor. So if you are going to err, err on the side of things getting progressively tighter. We are not talking about the kind of angles that will lock up after recoil, especially if nicely polished to fit. Steve PS...I don't know how to do pictures yet.

BTW, I had envisioned the scribe mark to be at the rear of the hook facing the slide, not down the side of the hook, as per your drawing...good luck!!

Yikes, I sounded like a curmudgeon a bit ago...replace "WILL NOT GET TIGHTER" to "will be as tight as it gets" and if the slider just got started over it, perhaps tight enough...not here to poo poo anyones' ideas, as I am a rank hobbyist...Steve

Well I went out to my workshop today after work and started filing and smoking the single claw (foot) on my rear ring. This time I did not worry about having the foot bearing on the barrels and just focused on having the flat area on the bottom of the ring bearing on the top of the base plate.

But then I started wondering about something I was doing. I have been using a steel bar 1" in diameter and approx. the length of the scope and attached my rings to this bar. This bar actually is used to lap 1" scope rings. I did this simply to avoid risking damage to the scope that I am going to use while I am doing the fitting of the rings to the bases. So, now I am wondering at what point should I attach the actual scope to the rings. Seems like I should do this before the very final fitting of the rear foot. Possibly the scope might fit slightly different than the steel bar....I don't see why it should but if it did this might affect the fit. And once I mount the rings to the actual scope and finish the fitting to the base plate is there any problem or issues with removing the rings to touch up the rings, final polish and blue them or even engrave them (not this time but just in theory on the engraving). Will removing the rings from the scope and later reinstalling the rings affect or change the fit? Again, doesn't seem like it would but wondering what others think.

Thanks,

Ron

Put the scope in and check. When the rear ring, without fitting the slider is down on the base, check the scope collimation. When it is right, that is you have adjusted the height by removing the right amount of the flat area that contacts the base, STOP and fit the groove/slider. This also means that if you have to lower the rear ring height, you will probably also have to reshape the bottom of the claw to just clear the bottom of the slot, since you have in effect lowered it, too. After you fit the slider IT IS TOO LATE TO ADJUST HEIGHT ANY MORE, as you would then move/ drop the groove BELOW the slider, loosening it, and you get to start over! After the slider is fitted, you can only polish other surfaces, so if you want the slider groove/slider polished, then let polishing (say with 400 sandpaper on a tiny file) accomplish the last removal of metal in the fitting process. Polishing the rest, blueing, and removal of the ring tops should have no detrimental effect IMHO, but I wouldn't get carried away on the sides of the claws, for sure. If at the end of the day you have to slightly adjust elevation, front or back, then light shimming of the rings, or milling of the rings might accomplish it. Probably your scope adjustment range will do it, but a centered scope is the goal...Steve

Ron,

A new front base is "skim"milled on top, but especially in the dovetail cut for the plate. At this point the plate will not fit into the dovetail, so isn't installed.Since the plate comes already fit to the ring, the reason for milling the dovetail is to level the whole assy. and insure it is parallel to the water table.

In boresighting,the chord is only to hold everything together, so you can determine the height of the rear ring.The rifle is not fired, and the scope is not adjusted.The boresighting is done by adjusting the height of the adjustable block under the scope.Since the reticle is centered before boresighting to find the correct height of the ring,maximum adjustment will be avaliable to sight it in, when the job is completed.

There are a couple reasons not to have the feet(in your case foot)bear hard on the barrel.Certainly, dirt/trash is a real concern;but also bearing on the barrel puts pressure on the solder joint between the rear base and barrel.When the rifle is fired in this condition,it "shocks" the solder joint.I have seen a rear base come loose because of this(I understand yours is screwed on).Also, if the feet bear on the barrel,it affects the fitting of the slider to the slot.The reason to have the feet close is for strength.

You are lucky to havs a Tig welder.

Mike

Steve,

Fitting the slider to the feet, the way I learned,takes the "slack" out by the bottom of the slider bearing on the bottom of the slot in the feet(which is a little proud)while this forces the slider up to bear on the bottom of the slot in the base.This takes out the tolerances necessary in manufacture,and it is easier to fit, since you are not filing blind in a slot.The slot in the feet being proud of the slot in the base is what forcrs the ring down.In fitting the slider,tapping it into the slot with a drift and small hammer,and fileing where the drag marks show interference,takes out the slack.Milling the slot in the feet, results in a slot parallel to the top of the base, and the slider needs to be parallel, to insure maximum contact and not wedge in so tight it is hard to remove the scope.The top of the base has been "skim"milled to make it level and parallel to the water table.The area that sits on the top of the base(which has been leveled)has been milled parallel, while milling to adjust the height, and usually "spotted in" to insure even bearing (one of the reasons the feet should be clear of the barrel).This "milling"can be done by fileing, but the fitting will take a lot of time and will be highly dependent on the skill of the workman.Mounts can, and do, sometimes get loose after 50 or 60 years of use;but it is much easier to correct this by replacing/refitting the slider.If the slot in the feet is not proud of the slot in the base, you can't refit it with just a new slider.

Mike

Hey, Mike--you are totally right about the future refitting--it would be vastly easier and better to just install another slide, which cannot be done if the feet are lowered. Thanks for the patient tutorial! Sometimes we have to talk it through, thinking out loud in order to really understand. And taking up the slack at the top of the slider groove is key, although it occurred my way as well. I am really enthused to learn these techniques. Thanks, again...Steve

Mike: Is there any way, short of owning some hydraulic setup, to force the base onto the hooks in the manner you described, even if the front base could be removed? It must have required great force if you had to scrape away a burr of metal from their joining. Steve

Steve,

I think so, I mentioned earlier that I thought taking the plate out of it's dovetail and drive it onto the hooks(ring locked upside down in a vise)with a drift and small hammer.This won't work if there is no plate(the solid ones I've seen were intended for the barrel of a bolt gun, ahead of the action. A small "truckload tool sale" hydraulic press(6 ton size)is not very expensive, and useful for a lot of things. A press like this is just an "H" frame with a smsll bottle jack supplying the power.You figured out, all by your self, how to make workable claw mounts, there is no doubt you could make one.

Mike

Mike, one more question: I presume since we are talking about a press fit, that the hooks are shaped to what we want them to be BUT A LITTLE PROUD? That is, shaped to the angle at the top of the hook and the curve at the bottom, with just enough extra to achieve a bit of "metal smear." The bases and hooks both making way under pressure, but fitted almost as peened together? Just trying to understand...STeve

Just looked at the set I made and "I WAS WRONG" the flat is on the lower side of the rear ring leg and the bevel on the top. Too many things going on can't remember them all.

It has been a while and I'm in the process of repairing another drilling, lock should be back soon. The other side was almost as bad.

oskar,

Good on you, I like to see these "old warriors"saved and brought back to life, when possible.

Mike

Steve, I don't think thay make them proud on purpose, I think they make them the width of the opening in the plate, but with a little manufacturing tolerance, a little bit usually rolls up.It might even do it if they are the same width.Since the manufacturer makes both, they can make the contour of the top of the hook the same as the inside of the plate(actually, the reverse).The hooks would be a little shorter than the thickness of the plate,otherwise it would hit the dovetail in the base.

Mike

Mike: I was trying to understand from where the metal rolls up. If I formed them too well, where would the resistance be when driving the base onto the hooks?

BTW, Oskar used a laser bore sighter to help align the rings. I assume one that fits in the chamber. He pointed it at a distant object and determined if the rings were well positioned with a scope laid in them, and the centered scope being moved by fitting to zero in on the laser mark. It wasn't a bore sighter that fits in the end of the barrel and looks back at the scope...and he did a neat job that resulted in a good group. (super schussleistung!) Your rear block with elevation screw just makes really good sense, though, and I would have done that had I known. It would have saved me some time.

Oskar, keep us abreast of your drilling repair project! Steve

Oskar, did someone use that stock to knock a dying rabbit in the head? I am amazed and depressed at the fine guns that are broken doing just that! You won't catch me breaking a stock to save a critter from an extra 20 seconds of suffering...would be like dodging a squirrel while driving a massive RV--wrong priorities.

Steve,

You usually find it on the side(s) of one or the other of the hooks, and maybe at the rear surface.This is usually very minor and is only a product of the tight fit of the hooks to the plate.The importance is only that they should be scraped off,so the ring fits flat onto the plate before boresighting with the adjustable block.With regard to the lazer bore sighter, I'm sure it will work.The procedures I described were thought out a long time before lazer bore sighters were invented.I wouldn't be surprised, at all,to walk into a shop and find them using one now.To boresight the traditional way, you have to have a vise located so you can see through a window or open door(Fred sighted on a transformer,down the street from the shop).With a lazer sighter, I guess the vise location wouldn't matter.

Mike

Mike, Just wanted to let you know that I tried your method of bore sighting and it worked well. The screw and steel plate worked very nicely and I used rubber surgical tubing to keep the scope in place. Really very simple although at this point I have only boresighted at 25 yds. I will have to find a location where I can boresight to 100 yds. Seems like I read somewhere that a rifle boresighted at 25 yds should come out about the same at 100 yds but I may be remembering this incorrectly. I also tried using a conventional boresighter and it came out the same as using the above method which surprised me. On a driling the bore is so much lower than the scope that it seems like a conventional boresighter would not work but they both came out about the same? From the measurements it looks like I will have to mill off about .043" from the bottom of the rear scope ring to get the scope where it needs to be. I also may have to take a little bit off the rear of the front feet as moving the scope down enough in the rear to boresight it makes the front ring pretty much bottom out on the base. I hesitate to take any off the bottom of the front ring bases where they contact the dovetail base plate but if I don't I believe the scope will be under slight tension when it is clicked into the rear base.

Any thoughts or advice is welcome.

Thanks,

Ron

Ron, think it out well before altering the front claws! Some of the European makers create claw mounts with purposeful tension (in fact this has been an on-going criticism of claw mounts, as mentioned in Klupp's book, Der Drilling). I have heard that their goal was to see the rear ring rise up 1/4 inch as soon as the locking slide was pulled back. They seem to have wanted to err on the side of levered in tight vs. worrying about any tension introduced to the scope. Swing mounts, when properly adjusted, are thought to be more tension-free. Sounds like you are being precise! Steve

Ron,

I try to boresight around 100yds, but I'm not sure it is all that critical,just find a location as far away as is convienent.As long as the result is within the range of adjustment of the scope, you should be ok.I fit a set of "Contra Einhackmontage"(reverse claw mounts) onto a boltgun when I lived in Germany.They were made to screw onto standard recievers, but my military action didn't fit exactly and I wound up having to scrape the front ring in.My "shop" was in a "maids room"and the one window was too high to see any target to boresight it. I solved the problem by tapeing a piece of paper with two dots the same distance apart as the distance between the centerlines of the scope and barrel.I sighted the barrel on the lower dot and the scope on the upper dot.The distance was about 5 feet. It worked. I'm surprised the conventional boresighter worked, but I'm often surprised.

Mike

Steve, Thanks for your thoughts on the tension on the scope. I think I remember reading that it is preferred that there be a slight bit of upward tension on the scope with claw mounts. I once had a swing mount installed a few years ago before I got brave enough to work on these on my own and I was told that even with a swing mount a very slight upward tension in the scope is preferred. So, I will go very slowly on the front rings and I may not need to take any off at all. I'll have to check when I get home but I an not sure the scope would rise more than a 1/4" if released from the rear slider.

Thanks, Ron