|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

1

|

2

|

3

|

4

|

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

|

12

|

13

|

14

|

15

|

16

|

17

|

18

|

|

19

|

20

|

21

|

22

|

23

|

24

|

25

|

|

26

|

27

|

28

|

29

|

30

|

31

|

|

|

|

Forums10

Topics38,506

Posts545,608

Members14,419

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Dec 2001

Posts: 3,964 Likes: 89

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,964 Likes: 89 |

Weren't most of the billets (rods) sourced from the rolling mills? I believe they were more or less factories and capable of quickly turning out very large quantities for the trade.

When an old man dies a library burns to the ground. (Old African proverb)

|

|

|

|

|

Joined: Jan 2006

Posts: 9,427 Likes: 315

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,427 Likes: 315 |

Joe is correct. Even by the mid-1800s rolling mills were in operation. PeteM has an image of a patent drawing on his site, but I don't know the date. Engines Of War: or, Historical and Experimental Observations on Ancient And Modern Warlike Machines And Implements, Including the Manufacture of Guns, Gunpowder, and Swords with remarks on Bronze, Iron, Steel, &c. Henry Wilkinson, M.R.A.S. London 1841p. 70 Part III On The Manufacture of Fire-Arms, And Modern Improvements. http://books.google.com/books?id=0XJeF_oa3SMC For the finest...barrels, a certain proportion of scrap steel, such as broken coach-springs, is cut into pieces and mixed with the iron by the operation called puddling, by which the steel loses a considerable portion of its carbon, and becomes converted to mild steel, uniting readily with the iron, and greatly increasing the variegation and beauty of the twist. In whatever manner the iron may be prepared, the operation of drawing it out into ribands for twisting is the same. This is effected by passing the bars, while red hot, between rollers until extended several yards in length, about half an inch wide, and varying in thickness according to whichever part of the barrel it may be intended to form: these ribands are cut into convenient lengths, each being sufficient to form one-third of a barrel...

|

|

|

|

|

Joined: Dec 2001

Posts: 3,964 Likes: 89

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,964 Likes: 89 |

Drew, somewhere around here I have a woodcut of a 18th century rolling mill. I suspect they have been around a lot longer than commonly thought. Will try to find it.

When an old man dies a library burns to the ground. (Old African proverb)

|

|

|

|

|

Joined: Dec 2001

Posts: 3,964 Likes: 89

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,964 Likes: 89 |

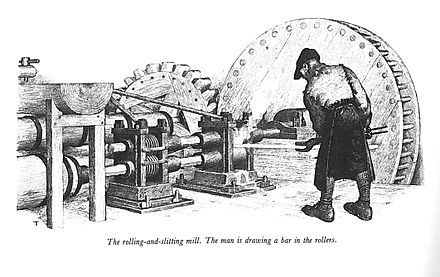

Not the one I was thinking of but this early rolling mill is from the late 18th century and similar to the one used by Paul Revere. Notice it appears to be water driven and I imagine the cog wheel is wooden. The level of sophistication in industry during the 18th century amazes me.

When an old man dies a library burns to the ground. (Old African proverb)

|

|

|

|

|

Joined: Feb 2008

Posts: 11,345 Likes: 390

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,345 Likes: 390 |

Joe, I'd guess you are correct that the 18th century mill was water wheel driven, but I think the larger drive gear is part of a very old technology that is being reintroduced as "new and superior". Google Tsubaki Pin Gear, or just Pin Gear and you'll see what I mean.

As they say, "nothing new under the sun."

The coupling of the rolling mill stand to the slitter stand suggests that even this mill process had evolved over time from something even simpler.

A true sign of mental illness is any gun owner who would vote for an Anti-Gunner like Joe Biden.

|

|

|

|

|

Joined: Jan 2006

Posts: 9,427 Likes: 315

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,427 Likes: 315 |

"Venus at the Forge of Vulcan", Jan Brueghel the Younger of Antwerp, Belgium c. 1605  Fellas on the right are using water wheel powered grinding stones and (foreground) trip hammers

|

|

|

|

|

Joined: Jan 2006

Posts: 9,427 Likes: 315

Sidelock

|

OP

Sidelock

Joined: Jan 2006

Posts: 9,427 Likes: 315 |

A thread from the early days of our Damascus research with several images posted by PeteM, including fellas holding rods fresh from the rolling mill http://www.doublegunshop.com/forums/ubbt...&PHPSESSID=

|

|

|

|

|

Joined: Feb 2009

Posts: 7,464 Likes: 212

Sidelock

|

Sidelock

Joined: Feb 2009

Posts: 7,464 Likes: 212 |

Tough to tell, but this may be a rifling machine. That twist on the bottom looks fixed to a gear and may be a way to move the work along the carriage. Nothing on the setup look 'quick release' to get hot work on and off before it cools to unworkable. Just wondering, appreciate that uncover these records.

|

|

|

|

|

Joined: Dec 2001

Posts: 775

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 775 |

Steve and others: I think you may be overestimating the time required to make a barrel if you are assuming that only one barrel was being forged at a time. I believe that more time is required for heating the metal to welding temperature than the time available for hammering before the metal cools below welding temperature, so I would expect that for efficiency, work would be carried out on more than one tube at a time, with one or two in the fire heating while one was being hammered. I was fortunate to heve grown up in a small town with an old time, 3rd generation blacksmith, and watched him for many hours, so I have a good idea of the processes, and that is what I base my comments on.

|

|

|

|

|