|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,433

Posts544,712

Members14,402

| |

Most Online1,258

Mar 29th, 2024

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

What do you folks use to hold a monobloc in the lathe to bore for sleeving?

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

B. Graham,

The way I learned is to turn the reamers in the headstock, center the barrel being reamed with a solid center in the tailstock and push it onto the reamer with the tailstock, while "dogging" it to prevent turning with a handvise( vise grips will work) clamped to the locking lugs, riding on the carriage. By doing it this way, before cutting the barrels off, you preserve the convergence of the barrels. If the barrels have been cut already( or if you made an actual monobloc), you will need to set it up at the correct angles in a mill with an angle plate and bored with a boring bar. Others may very well do it a different way.

Mike

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

Thanks Mike. I think I understand what you're describing. I was aware of a choke tube fixture for doubles that Colonial made. Jack First listed in an old catalog, but they do not have one.

One thought, probably flawed, was to use a reamer large enough to ream the monobloc by hand. Not sure if there are reamers for that use that would large enough. I'm assuming you'd cut enough to erase the rim cuts.

If I can figure out a strategy, and find new tubes, I would be permitted to do this at school.

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

Bill,

As long as the old barrels are not cut off, you shouldn't need a fixture. You can get reamers from VME, mentioned in the broken bridle screw thread above. They won't be cheap, but will be much better than trying to use a twist drill. As long as a rifle chamber is not involved (a rifle chamber has too much taper for a reamer to work until it is counterbored large enough to get past the extractor cut then drilled straight. The counterbore is necessary to prevent the drill flutes "grabbing").My friend Walter kept the proper size reamers for 16 ga., right on his lathe, so I didn't have to calculate the correct sizes or the difference in diameters between each step. As I recall, I used about 3 different sizes. You do have to ream past the rim recess. The new tubes were made already turned to size and they set the required diameter of the hole. Since the joint is so large, soft solder is plenty strong enough. I think Walther has a website where you can find the usual standard dimensions of new tubes. This would be useful, even if you turn your own blank from Numrich Arms barrels.

If the barrels have been cut off, the boring bar in a mill is much less likely to get messed up than trying to ream or drill it without a good guide. On the other hand, there is little doubt that barrel sets have been successfully finished working around a good many mistakes. The maker will know the mistakes but others won't. Good luck.

Mike

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

Thanks Mike. Do you have the website address, or last name for Walter?

The barrels have not been cut off yet. I think in this case, factoring in costs and the equipment, it would simpler to go ahead and cut them, and use the mill/boring bar method.

The barrels in question are a set of damascus tubes from a Charles Osborne 12ga boxlock. I have $80 in the gun, so the risks are low. I would like to learn this process, and get school credit for the experiment.

A source for tubes I can afford are probably the biggest obstacle at this point.

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

Bill,

Walters last name is Grass. He lived in Muennerstadt in Germany, but the last time I saw him was Jan. 1982. He was planning his retirement then, infact I helped him renovate his retirement home. Considering the length of time since then I'm not sure he is still living. He was a WW2 veteran and would be over 90 years old now. He would not have a website even if living. There are others that do this work though, such as Henneburger.de, or Zimmerman.de, that do have a website. The total cost would be pretty high and there would likely be a long lead time.

Mike

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

SKB,

I think Walther has a US operation and their barrel blanks would be fully prepared, although a little pricy. To find them in their website, you may need to wade into the German parts.

Mike

|

|

|

|

|

Joined: Dec 2001

Posts: 6,990 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,990 Likes: 402 |

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

SKB,

That is who I was talking about, they also have fully contoured blanks.

Mike

Last edited by Der Ami; 09/27/19 01:31 PM.

|

|

|

|

|

Joined: May 2010

Posts: 1,524 Likes: 73

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,524 Likes: 73 |

B. Graham,

The way I learned is to turn the reamers in the headstock, center the barrel being reamed with a solid center in the tailstock and push it onto the reamer with the tailstock, while "dogging" it to prevent turning with a handvise( vise grips will work) clamped to the locking lugs, riding on the carriage. By doing it this way, before cutting the barrels off, you preserve the convergence of the barrels. If the barrels have been cut already( or if you made an actual monobloc), you will need to set it up at the correct angles in a mill with an angle plate and bored with a boring bar. Others may very well do it a different way.

Mike The idea of doing that scares the hell out of me !

|

|

|

|

|

Joined: Dec 2001

Posts: 6,990 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,990 Likes: 402 |

Similar to how I was taught in gunsmithing school to chamber a rifle. A chamber reamer with a dog centered on the tailstock and live center and the barrel spinning in a steady rest, hold the dog in your hand. I do not chamber rifles that way any longer!

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

Gunman, SKB,

Turning at 22-28RPM is not scary at all. This is why I kept my Atlas lathe when I got the Clausing. The slowest the Clausing will turn is 54 RPM. Most of the modern lathes turn 70-90RPM in The gunsmith sizes(12-14"). I chamber between a center and steady rest pushing the reamer with a solid center and the tailstock spindle extended pretty far. I dog the reamer with either a box end wrench or tap handle held in my hand so that if it hangs up it will simply straighten my fingers out and release the reamer. Both the box end and tap wrench will clear the bed and turn with the barrel harmlessly. With the right size pilot, the reamer will follow the bore this way. I didn't go to gunsmith school, I learned this from an old gunsmith( except I figured out myself to use a "flag" on the tailstock spindle and a dial indicator when I get close.

Mike

|

|

|

|

|

Joined: May 2010

Posts: 1,524 Likes: 73

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,524 Likes: 73 |

Its not the speed its the way you are suggesting .I have seen numerous methods of reaming out back ends including the one you suggest .I have only seen two I would use .

All I can say is good luck .

P S. I have sleeved a lot of guns so I do have some idea as to what I am saying .

|

|

|

|

|

Joined: Dec 2001

Posts: 6,990 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,990 Likes: 402 |

Gunman,

How do you go about it?

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

Gunman,

Thanks, I have already had good luck. I know there are different ways of doing things. Do what works best for you, using the equipment you have. Change only if you think some other way will be better for you. As for myself, I am about at the end of doing substantial work. I was watching "Life Below Zero" where one of the people caught a spawned out "ghost" Salmon. It reminded me of me.

Mike

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

I'm going with the route of boring the monobloc on a mill. The tubes have been cut to 3", and the bloc has been faced.

The school has boring equipment of course, but I was wondering, for this use case, what do people like to use for boring this length of tube vertically?

Also, what is best approach to hold the block securely, considering the taper of the remaining tubes, and keeping the boring straight.

Tubes were found at Holt's: 28 1/8" unchambered Westley Richards tubes.

|

|

|

|

|

Joined: Nov 2018

Posts: 98 Likes: 8

Sidelock

|

Sidelock

Joined: Nov 2018

Posts: 98 Likes: 8 |

First, use the largest diameter boring tool you can fit in the hole for absolute rigidity as to avoid chatter. Make sure the tool is centered correctly.

Indicate the face of the monobloc to be certain it is square and parallel.

Of course use a tool which is long enough to bore the hole in one pass all the way through.

use gage pins if you have them to measure the hole diameter as you progress.

|

|

|

|

|

Joined: May 2010

Posts: 1,524 Likes: 73

Sidelock

|

Sidelock

Joined: May 2010

Posts: 1,524 Likes: 73 |

Gunman,

How do you go about it? I dont any more I retired and the tooling was sold off . Basicaly the barels were cut off at 3&1/2" inches a centered mandrel was put in the chamber and held between centers , the back ends then clamped in a in a jig mounted on the cross slide by the lumps . The boring was done from the front/muzzel end with reamer drills and then finished to size with boring tool driven in the head stock . It was then faced off to length with a large diameter end mill . This was a one station operation so that the facing off was true to the bores .This facing off was the key to good joints .

|

|

|

|

|

Joined: May 2008

Posts: 918 Likes: 246

Sidelock

|

Sidelock

Joined: May 2008

Posts: 918 Likes: 246 |

Gunman,

How do you go about it? I dont any more I retired and the tooling was sold off . Basicaly the barels were cut off at 3&1/2" inches a centered mandrel was put in the chamber and held between centers , the back ends then clamped in a in a jig mounted on the cross slide by the lumps . The boring was done from the front/muzzel end with reamer drills and then finished to size with boring tool driven in the head stock . It was then faced off to length with a large diameter end mill . This was a one station operation so that the facing off was true to the bores .This facing off was the key to good joints . It scares me too. You lads should listen to what Gunman is teaching you, a variation of the classic "line boring" method using an accurate lathe you learn in engineering shop practices. More accurate than using a vertical mill. Also he is dead on in the facing method, I even went so far as to make my own milling cutter for this work in order to get seamless fit of barrels to monobloc. Cutting the proper facing of the monobloc is the reason masters like Kirk Merrington can sleeve shotguns seamlessly without tig welding. When you build a made for purpose jig to mount to the lathe cross slide do not use the compound, but remove it and mount the jig's adjustable base directly to the cross slide base center hole(where the compound fits). Make sure the cross slide has all excess play to the lathe ways adjusted out. I use a 2 inch hardened and ground machinist vice mounted to the cross slide (with adjustable base to the vice/cross slide interface) to hold the lumps of the monobloc securely. You will make the adjustable vice base of sufficient height to have the monobloc at center line of the headstock to tailstock when the monobloc is secured in the vice jaws. The ground and hardened vice jaws will keep from marring the surface of the monobloc lumps-but I use brass shim anyway. I am nearly 80 years old now and I suppose you all are lads to me. Also sold my lathe, vertical and horizontal mills and tooling last year. Bv

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

My sincere thanks to all who have contributed here. I am 53, in a career I donít much care for but am thankful for nonetheless. This kind of endeavor is about my pursuit of the skills to make second a career, that I actually like, if and when I can afford to step away from the current one. So, thank you for helping me learn.

I do not yet know what method weíll use to bore and sleeve, but the monobloc is cut, square, nicely faced, and the tubes have been bought in the UK. When they arrive, weíll resume.

|

|

|

|

|

Joined: Aug 2018

Posts: 305 Likes: 7

Sidelock

|

Sidelock

Joined: Aug 2018

Posts: 305 Likes: 7 |

Awesome thread. Pics of anyone's set up would be invaluable.

I am just a couple years older than BGraham but my interest in double gun resto and repair is a culmination of taking many individual interests and focusing them into one object and eliminating the other objects as distraction in my life.

Guns, hunting, metal working, woodworking, exploration, art, history and fraternity all come into a very satisfying contentment in vintage double shotguns.

This is a great forum and I am so respectful to all those who are mastering/have mastered the skills to keep these guns alive and kicking.

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

B. Graham,

A bit of unsolicited advice, most people don't listen to me though. I wouldn't just quit my present job, work until you have full retirement. It is hard to start fresh and make a living as a gunsmith, a decent retirement helps a lot. You seem to be rounding up equipment and experience now, while you are still working, that is good. I was not much older than you are now when I retired. There is one thing that hits us all, age is a bear. There are a lot more than 10 years between 50 years old and 60 and especially between 60 and 70. Age influences everything you do, unless you are very very lucky. If you can't stand in front of a lathe or mill very long, it is really hard to work from a stool and dangerous also. Hand polishing a gun or letting in a stock is hardly possible, sitting on a stool. Keep all this in mind when gathering equipment and setting up your shop as well as deciding what to specialize in. good luck.

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

Thanks, Brother. I appreciate the advice.

Job: I have no plan to quit my present job. It's looking like 10-15 more in my future. That said, the company I work for it notorious for sending people packing in large numbers, and often-times the older employees. I have been somewhat successful in modestly "refreshing" old neglected doubles, so if my career ends sooner than I wish, I should have some skill already to help us get by, but I know this work will not currently cover my families costs at this time.

Health: I polished a pitted Colt 1908 by hand for 4 hours last night for my first bluing project of the school curriculum. One has to prove you can polish by hand before they let you at the wheels. At the end of class at 10:00PM, my arthritic hands were screaming, and my arms were falling off. So, I hear you!

In order of specialization priorities, I'm interested in doubles, old steel S&W revolvers, classic carbon steel 1911's, and an odd rifle here and there. Doubles are the primary area of focus. I do plan to get back to damascus refinishing at some point, but my facilities don't make that a scalable endeavor. I had some good results in the past, but the cost was too high.

I'm doing this because I love it, and that's the best part of it.

|

|

|

|

|

Joined: Jul 2012

Posts: 4,455 Likes: 202

Sidelock

|

Sidelock

Joined: Jul 2012

Posts: 4,455 Likes: 202 |

B. Graham,

More unsolicited advice. If your company has a retirement plan that you are vested in and you are let go, leave the retirement in place, if you can. Usually if you "cash out", you get only what you "put in" and would loose any interest or company contributions. They will "suggest" you cash out because it is better for them. A reduced pension is better than no pension and it will still accrue interest on what is left in, until you reach retirement age. Of course, this doesn't apply if they are "going under". Not my business, I just had friends hurt by "cashing out" and having to start over late in life.

Mike

|

|

|

|

|

Joined: Aug 2013

Posts: 973 Likes: 23

Sidelock

|

OP

Sidelock

Joined: Aug 2013

Posts: 973 Likes: 23 |

No pension with this company anymore. That match up to 5% and give you 1% as a gift. You have to still be employed as of 12/15 of each, or youíre out of luck for that year. So, this time of year is when people start to get nervous about layoffs. The company will likely never go out of business.

|

|

|

|

|

Joined: Dec 2001

Posts: 363 Likes: 16

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 363 Likes: 16 |

I would suggest you take heed of Gunmans comments. I can assure you not all shotguns barrels have the chamber aligned with the bore, let alone the muzzle. Maybe most do, but not all. I learned this the hard way, but was able to recover. You must bore out the back end indicating on the original chamber as your guide. You only get one shot at this.

Dennis Potter

|

|

|

|

|

Joined: May 2008

Posts: 918 Likes: 246

Sidelock

|

Sidelock

Joined: May 2008

Posts: 918 Likes: 246 |

Dennis;

Your article on choke reaming in the recent Shooting Sportsman magazine was well written and right to the point of demonstrating that not all chokes are created equal. You are to be congratulated for your good photography and writing skills.

Kindest Regards;

|

|

|

|

|

Joined: Dec 2001

Posts: 363 Likes: 16

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 363 Likes: 16 |

I missed adding that you must indicate both the rear and front of the chamber, not just the rear. Sorry

Dennis Potter

|

|

|

|

|

Joined: Feb 2013

Posts: 474 Likes: 65

Sidelock

|

Sidelock

Joined: Feb 2013

Posts: 474 Likes: 65 |

After being surprised by an American gun or two but still being able to save my arse I now bore all monoblocks in the mill after cutting. Normally you can follow the chamber, but a few have required redirection.

A.M. Little Bespoke Gunmakers LLC.

Mineola, TX

Michael08TDK@yahoo.com

682-554-0044

|

|

|

|

|

Joined: Dec 2001

Posts: 363 Likes: 16

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 363 Likes: 16 |

Thanks for the undeserved kind works re the choke article, but that is not my work. I dropped the magazine a few years ago, so I cannot easily read the article. It is nice that they are publishing some technical information.

Dennis Potter

|

|

|

|

|

Joined: Jan 2002

Posts: 404

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 404 |

Dennis your right the article is by Delbert Whitman Jr of Traverse City, Michigan, It's a good article about what I always suspected that with the new plastic shot cups chokes are much tighter than with the old fiber wads.

|

|

|

|

|

Joined: Apr 2005

Posts: 1,688 Likes: 31

Sidelock

|

Sidelock

Joined: Apr 2005

Posts: 1,688 Likes: 31 |

Correction:- Patterns may be tighter with plastic wads compared with fibre wads , but chokes do not change .

|

|

|

|

|

Joined: Jan 2002

Posts: 9,735 Likes: 740

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 9,735 Likes: 740 |

After being surprised by an American gun or two but still being able to save my arse I now bore all monoblocks in the mill after cutting. Normally you can follow the chamber, but a few have required redirection. Calling the cut chamber section of a set of barrels a monoblock is not technically correct. A monoblock is just that, a single piece of steel. A cut off section of barrels is not a monoblock, unless it started out as one piece. Most, donít. Best, Ted

|

|

|

|

|

Joined: Dec 2001

Posts: 6,990 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,990 Likes: 402 |

I use the British gunmaking term "trousers" as taught to me by len Bull.

|

|

|

|

|

Joined: Feb 2013

Posts: 474 Likes: 65

Sidelock

|

Sidelock

Joined: Feb 2013

Posts: 474 Likes: 65 |

After being surprised by an American gun or two but still being able to save my arse I now bore all monoblocks in the mill after cutting. Normally you can follow the chamber, but a few have required redirection. Calling the cut chamber section of a set of barrels a monoblock is not technically correct. A monoblock is just that, a single piece of steel. A cut off section of barrels is not a monoblock, unless it started out as one piece. Most, donít. Best, Ted Sure, if you want to be technical. Still, you knew what I was discussing. Iíll let others argue semantics and Iíll stick to the work.

A.M. Little Bespoke Gunmakers LLC.

Mineola, TX

Michael08TDK@yahoo.com

682-554-0044

|

|

|

|

|

Joined: Jan 2002

Posts: 9,735 Likes: 740

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 9,735 Likes: 740 |

It doesnít actually take any more effort to use the terminology correctly. A craftsman with a good grasp of the terms and the ability to help a layman with the description of the work is a better craftsman.

Best,

Ted

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

|

|

|

|

|

Joined: Feb 2013

Posts: 474 Likes: 65

Sidelock

|

Sidelock

Joined: Feb 2013

Posts: 474 Likes: 65 |

It doesnít actually take any more effort to use the terminology correctly. A craftsman with a good grasp of the terms and the ability to help a layman with the description of the work is a better craftsman.

Best,

Ted How many have you done?

A.M. Little Bespoke Gunmakers LLC.

Mineola, TX

Michael08TDK@yahoo.com

682-554-0044

|

|

|

|

|

Joined: Feb 2008

Posts: 11,331 Likes: 388

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,331 Likes: 388 |

Sure, if you want to be technical. Still, you knew what I was discussing. Iíll let others argue semantics and Iíll stick to the work.

Well, so much for not arguing, and sticking to "the work". I have to agree with Ted on this one. We've seen folks corrected for the use of incorrect terminology about a million tomes over the years on this forum. He's absolutely right, and there is nothing wrong with providing the correct information. For the record, I haven't done any pipe-fitting on any doubles, Well... you should know what I'm talking about...

A true sign of mental illness is any gun owner who would vote for an Anti-Gunner like Joe Biden.

|

|

|

|

|

Joined: Jan 2002

Posts: 7,700 Likes: 99

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 7,700 Likes: 99 |

Gunmaker did the only sleeving job I've ever needed. I don't care what he calls the process or the parts involved because he did a fantastic job on my Elsie Specialty. The man knows his craft...Geo

Last edited by Geo. Newbern; 10/29/19 02:13 PM. Reason: added pic

|

|

|

|

|

Joined: Feb 2008

Posts: 11,331 Likes: 388

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 11,331 Likes: 388 |

That does look like a good pipe-fitting job Geo. So what is the correct terminology for that forend? I call those things flotation pontoons. If King's Sterlingworth had one of those babies, it never would have sunk to the bottom of the Atlantic ocean during a blizzard.

Now all we need is a new thread to theorize about the cause of that barrel burst, with maybe some metallurgical analysis and photomicrographs of ferrous contamination or scale that somehow becomes manganese sulfide inclusions. I'd suspect an obstruction... possibly caused by the small graffiti artist who was writing things on the inside of the barrel.

A true sign of mental illness is any gun owner who would vote for an Anti-Gunner like Joe Biden.

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

It doesnít actually take any more effort to use the terminology correctly. A craftsman with a good grasp of the terms and the ability to help a layman with the description of the work is a better craftsman.

Best,

Ted How many have you done? Gunmaker If you ever need a bike chain fixed Ted is the mAn to call.

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

A lot of those barrel burst are caused by gremlins.

Dang it George no wonder you're a little shaky at times...did you survive that ?

|

|

|

|

|

Joined: Dec 2001

Posts: 6,990 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,990 Likes: 402 |

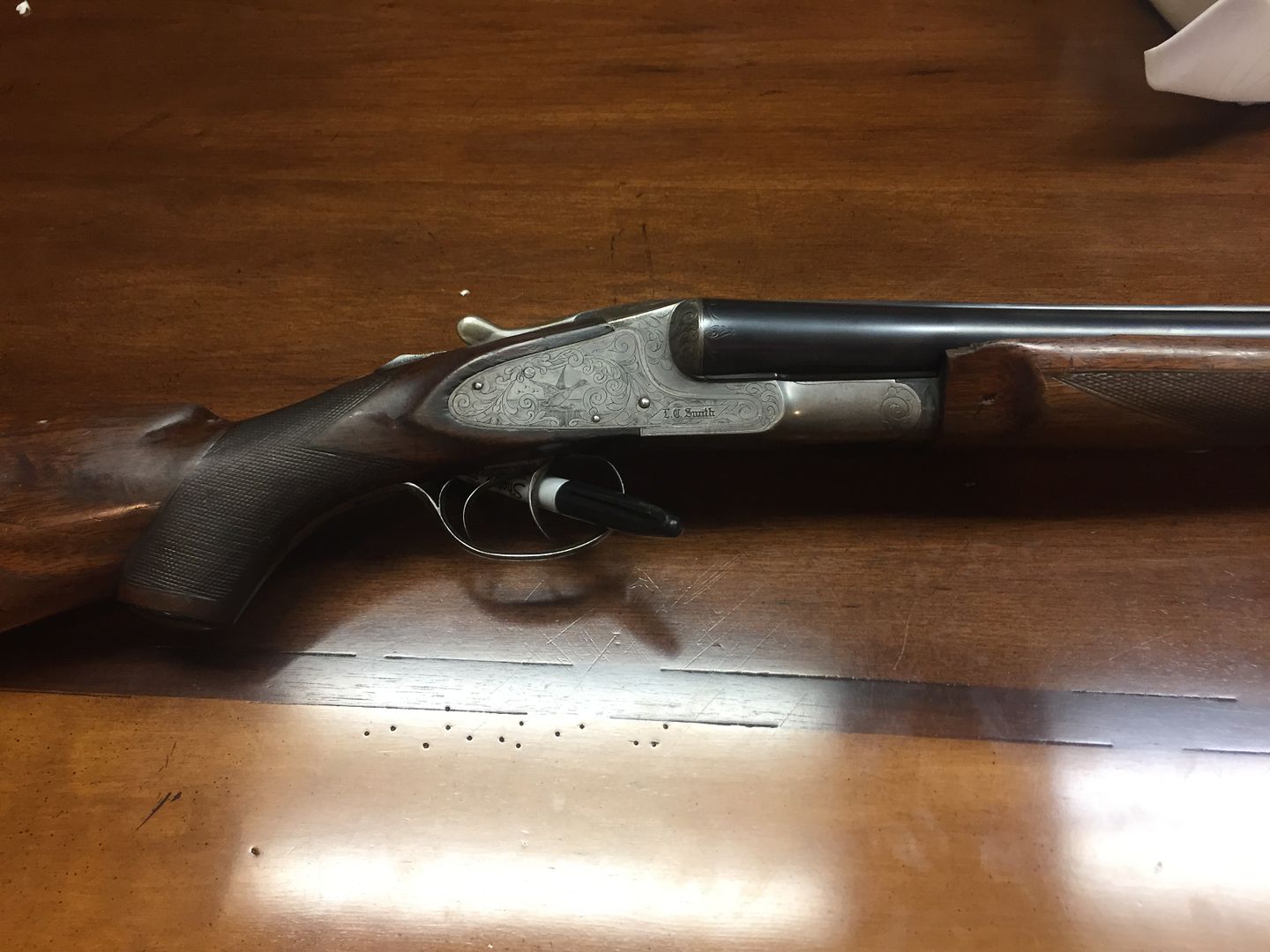

Yup I have seen this one in the flesh, superb job on sleeping one barrel on the old LC Smith. Aaron does very nice work.

|

|

|

|

|

Joined: Jan 2002

Posts: 7,700 Likes: 99

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 7,700 Likes: 99 |

A lot of those barrel burst are caused by gremlins.

Dang it George no wonder you're a little shaky at times...did you survive that ? Worse'an that jOe, I bought it that way...Geo

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

Must be part of our Southern Heritage....

Hard to pass up a nice tOmato stake.

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

It doesnít actually take any more effort to use the terminology correctly. A craftsman with a good grasp of the terms and the ability to help a layman with the description of the work is a better craftsman.

Best,

Ted How many have you done? I don't think Ted is going to answer...let me take a wild guess. 0...ZerO...unO...zilzh Ted just likes to run his mouth and try and make people look dumb. His skill rAtio with that is also 0'

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

It doesnít actually take any more effort to use the terminology correctly. A craftsman with a good grasp of the terms and the ability to help a layman with the description of the work is a better craftsman.

Best,

Ted How many have you done? Put that in yer big viSe and smoke it Teddy....ahhhhh I knew Ted wouldn't touch your reply with 10 foot key board. How's it go ROTFLMAO...

|

|

|

|

|

Joined: Dec 2008

Posts: 277 Likes: 4

Sidelock

|

Sidelock

Joined: Dec 2008

Posts: 277 Likes: 4 |

Someone please educate meÖ. What exactly is sleeving a monoblock?

Are you talking the entire barrel Ö 26-30+ inches or are you talking the first few inches?

I do make barrels for the old Winchesters, so Iím not a complete novice. Just trying to expand my knowledge base.

Respectfully

Mike

|

|

|

|

|

Joined: Jan 2002

Posts: 9,735 Likes: 740

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 9,735 Likes: 740 |

Someone please educate meÖ. What exactly is sleeving a monoblock?

Are you talking the entire barrel Ö 26-30+ inches or are you talking the first few inches?

I do make barrels for the old Winchesters, so Iím not a complete novice. Just trying to expand my knowledge base.

Respectfully

Mike

jOe will be along to shower you with his knowledge on the process-after all,he has done the exact same number I have. Let us see how far the idiot savant of DGS gets you. Then, others will be along to actually answer your question. Best, Ted

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

The idiOt savant just replied...

|

|

|

|

|

Joined: Jan 2002

Posts: 9,735 Likes: 740

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 9,735 Likes: 740 |

The idiOt savant just replied... You didnít say much, though. Figured youíd shower us with knowledge the same way you shower your Depends adult diapers.... Best, Ted

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

|

|

|

|

|

Joined: Jan 2002

Posts: 9,735 Likes: 740

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 9,735 Likes: 740 |

The truth hurts, or, at the very least, it is a little bit clammy.

Best,

Ted

_____________________________

ROTFLMAO

|

|

|

|

|

Joined: Jan 2006

Posts: 15,456 Likes: 86

Sidelock

|

Sidelock

Joined: Jan 2006

Posts: 15,456 Likes: 86 |

You sure make the truth easy to see....

Read my signature line ol'truth teller.

|

|

|

|

|

Joined: Jan 2002

Posts: 9,735 Likes: 740

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 9,735 Likes: 740 |

Only thing you have exposed for the world to see is a pair of crummy vises, and lousy mounts for same.

Didnít you say one was a Wards? Hey, one other thing Iíve NEVER SEEN is somebody bragging about their Monkey Wards tools.

Best,

Ted

_______________________

Even your demons are cheap pricks.

|

|

|

|

|