|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

1 members (WJW),

1,065

guests, and

3

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics38,469

Posts545,142

Members14,409

| |

Most Online1,299

Apr 26th, 2024

|

|

|

|

Joined: Jul 2014

Posts: 427 Likes: 76

Sidelock

|

Sidelock

Joined: Jul 2014

Posts: 427 Likes: 76 |

I'm pretty sure Liege was a source for barrel tubes, to be later proofed in Britain.

British makers bought Belgian actions such as the Bastin action with sliding barrels (Google Purdey Bastin slide action for a fine example), to be made up in Britain. The Bastin action was used by a number of British makers, and it was one of the first non-Lefaucheux pinfire actions in Britain (a Francotte with Bastin action was used in the Trial of 1859). Some makers brought in barrelled actions (or possibly whole guns) from liege as well, with a British maker's name on the rib and Belgian action and barrel proofs as evidence. And some makers operated in both London and Liege, such as the Masu Brothers.

|

|

|

|

|

Joined: Feb 2016

Posts: 3,158 Likes: 319

Sidelock

|

OP

Sidelock

Joined: Feb 2016

Posts: 3,158 Likes: 319 |

This is a site which contains a scrapbook of memorabilia compiled by John Blanch over the course of some 60 years. I wrote and obtained a circa 1840 J.C. Reilly advertisement posted on this line above about a year ago. https://collections.royalarmouries.org/archive/rac-archive-391096.htmlIn view of the history written by Steve, I took another look at what might be in the notebooks. These entries look interesting and I'll attempt to obtain them: This might be the bill of sale for the original Beringer center-break gun purchased by Blanch in 1855: "p. 30 Bill with engraved bill-heading for Fusils Berenger, brevet S.G.D.G. Hippolyte Rochatte, eleve et successeur, 8 rue du Coq, St. Honore, for supply of 'Un fusil de Paris canons Leopold Bressard' and caps, primers and case to Monsieur Guy Christy. Change of address noted 'actuelllement 26 rue de la Monnaie, au coin de la rue de Rivoli', dated 22 Xbre 1855;" An indication of Blanch's interest in center-break breech-loaders "p. 28 Advertisement leaflet: Exposition Universelle de 1855. Fusils a bascule perfectionnes par E. Dufour... Chez Francis Marquis, arquebusier, 4 Boulevart des Italiens, Paris;""p. 12 Folding 'Plate 1' showing rotating chambered-breech firearms;"p. 4 Fourteen page leaflet by Joseph Lang, Cockspur Street, London, 'On the advantages of breech-loading guns over the old system of loading with a rod, by one who has used them for years';"

Baluch are not Brahui, Brahui are Baluch

|

|

|

|

|

Joined: Jul 2014

Posts: 427 Likes: 76

Sidelock

|

Sidelock

Joined: Jul 2014

Posts: 427 Likes: 76 |

Totally fascinating. Good luck with your research efforts! We are learning so much from them.

And I expect the Beringer bill is for a gun with barrels by Leopold Bernard, the greatest of the Parisian barrel makers. It is hard for modern eyes to decipher Victorian script!

|

|

|

|

|

Joined: Aug 2007

Posts: 10,784 Likes: 185

Sidelock

|

Sidelock

Joined: Aug 2007

Posts: 10,784 Likes: 185 |

.....It is hard for modern eyes to decipher Victorian script! Indeed, that calligraphy is all but a lot art. Although I cannot say I can pen it, I read it almost daily seeing the land notes for Alabama & Mississippi are penned in that script. Any idea how many makers from the little British Isles from the period passed thru Ličge or St. Etienne on their walkabout? Cheers, Raimey rse

|

|

|

|

|

Joined: Jul 2014

Posts: 427 Likes: 76

Sidelock

|

Sidelock

Joined: Jul 2014

Posts: 427 Likes: 76 |

For those with much patience and an interest in the state of gunmaking in 1862 in Britain, France and Belgium, the following may be of interest.

The International of 1862, or Great London Exposition, was a world's fair held from 1 May to 1 November 1862, beside the gardens of the Royal Horticultural Society, South Kensington, on a site that now houses museums including the Natural History Museum and the Science Museum. It was a follow-up to the Great Exhibition of 1851, and the exposition was sponsored by the Royal Society of Arts, Manufactures and Trade, and featured over 28,000 exhibitors from 36 countries, representing a wide range of industry, technology, and the arts. The exhibition attracted about 6.1 million visitors. The Record of the International Exhibition, published in 1862 (Glasgow, W. MacKenzie publishers), contains a section written by John Rigby, of William & John Rigby, Dublin, describing the content of the gun exhibits, and the state of gunmaking. It is one of the better summaries of what was happening in 1862. And yes, E. M. Reilly does get a mention, for a pinfire he exhibited.

The following is the text of that section in its entirety. Apologies for transcription errors, of which there must be some.

Gene, if you don't want this clogging your thread, I can move it elsewhere. I think it does go some ways towards answering the question of just how much influence Continental makers had over British makers, and vice versa. There was a lot of technological exchange, despite the politics of the day!

RECORD OF THE INTERNATIONAL EXHIBITION, 1862.

2. FIREARMS.

By John Rigby, Esq., A.M., of Messrs. William & John Rigby, Dublin.

THE period which has elapsed since the Exhibition of 1851 has been marked by an extraordinary activity of invention in the department of firearms. That this activity should be wholly attributed to the stimulus supplied by the public display of foreign inventions on that occasion, We do not undertake to say; but there can be no doubt that from that year dates a period of unusually rapid change, and unusually rapid development in the construction of small arms of every species. This revolution commenced among pistols by the introduction of the revolving principle, then affected military arms by the substitution of rifles for the smooth bore musket, and was continued in the numerous efforts to solve practically the important problem of loading all firearms at the breech.

Looking at the contributions of British exhibitors at Kensington, we can determine at a glance how far these revolutions have succeeded, and how far and in what departments there has been reaction from their effects. In the first, that affecting pistols for offensive and defensive purposes, the revolver has so completely displaced the old models that there is scarcely one of them to be seen, and the whole interest of the pistol question turns on the merit of the various patents which are before the public, and more especially on the comparatively recent application of the breech-loading idea to this form of weapon. In the second—the improvement of military arms—the success of the revolution is, if possible, more complete, and every branch of our service is now armed with the rifle. Its ultimate form may be still an undecided question, but there is no apparent possibility that the smooth bore, although still extensively used in foreign armies, will ever again be placed in the hands of a British soldier. In the third, namely, the substitution of breech-loading systems for muzzle-loading in sporting and military arms, the revolution is far from complete ; and although breech-loading has made great progress in' many directions, as for instance in shotguns for home use, and in carbines for cavalry, yet it cannot by any means he said that it either has or is likely soon to altogether supersede muzzle-loading, even in sporting arms.

If we compare the progress made in the manufacture of small arms by British exhibitors with that of their foreign rivals in this branch of industry, another consideration is at once forced on our notice, which is important as demonstrating the value to the country of Exhibitions like the present in stimulating invention, and generally in accelerating the progress of science as applied to manufactures. In 1851 an examination of small arms contributed by British manufacturers unmistakably revealed the fact that no change of importance in their form or construction—no invention of note had been introduced during a period of thirty years, since the date of the final establishment of the detonating system instead of the flint. There was not a single breech-loading gun in the whole collection ; and no proposal for breech-loading would be entertained by the leading manufacturers. There was nota military rifle worthy of the name, and military men ridiculed the idea whenever suggested of arming troops with a title. The state of knowledge on the subject may be inferred from the fact that the two-grooved Brunswick rifle then used by one of our regiments, was held up by these who led public opinion as the most perfect form of rifle which had ever been invented. Again, with respect to revolving pistols, the only type exhibited was that with multiple barrels, and there was not a single chamber revolver in the collection. What makes the state of knowledge in England in 1851 more remarkable, is the fact that for some years previously neighbouring nations had been as busy in invention as we had been supine. The chamber revolver had already reached in America the identical form which, without improvement or change, it holds to the present day, and all the obstacles which had hindered its success for two hundred years had been completely removed. The French military rifle had already passed through its various stages of development, and achieved the results whose publication startled all England from inactivity, and ended in completely revolutionizing in two years our military weapons. The inventions of Lefaucheux, Beringer, and others had already occupied public attention in France for many years, and their successful application of breech-loading to sporting arms was on the Continent an accomplished fact. During all this rapid progress abroad England remained inactive, and the few who devoted their energies to experiment in such directions were treated as visionaries. An examination of the present Exhibition reveals a singular change in all these respects, and true progress runs more danger now of being impeded by the hasty zeal of innovators than by incredulity or neglect. In fact it is in the English department that we must look in the year 1862 for the most advanced ideas in breech-loading, and the most perfect military rifle ; and the progress of British exhibitors in all branches of the manufacture is much more marked than that of their foreign competitors.

Before proceeding to examine the varieties of construction and the fertility of invention evidenced in the numerous systems and modifications of systems represented in the Exhibition, it will be well to look at the manufacture of firearms more in its commercial aspect. In the great centres of this industry—Birmingham, Liege, and St. Etienne—the extreme subdivision of labour has been always the course pursued to lower the cost of production. In Liege especially this course is followed to its furthest limit, and most successfully, in the manufacture of trade guns at a low price. The industrious population which inhabits the villages and populous country surrounding Liege for many miles, is all engaged in isolated branches of the trade. In one village every man is a lock-filer; in another all are engaged filing mounting; and these villages being favourably situated in a fertile country, the artisans can easily obtain the vegetables which form the principal part of their diet. This simplicity of life, aided by the plodding industry which belongs to their character, has enabled the Liegois to produce trade guns at a lower price than the Birmingham makers; and of late years, since the intercourse between the two countries has become greater, they have copied not unsuccessfully the substantial models of English guns, and adopted their improvements. The English workmen possess one advantage over the Liegois in the superiority of their tools, and they are now becoming alive to the necessity of calling in to their aid the superior resources of this country in machinery to enable them to compete with their foreign rivals. In the materials employed the balance of advantage is rather in favour of the Belgian and French manufacturers; for whatever may be said of the steel it is an undoubted fact that in iron and wood suited for gun work, we are not in as good a position as they are. Walnut, which is now almost universally used for gun stocks, is a scarce timber in England, and for years we have been obliged to seek our supplies abroad. Italy has exported the greater portion of the wood used in our Government arms for some time, and large numbers of French and other Continental gun stocks are also sent into this country. That this should be so is easily understood; but that we should be inferior in the preparation of iron for gun barrels, and in skill in forging them, reveals an unsoundness in one branch of our gun manufacture which ought not to exist. We do not now allude to the barrels of military guns, which, owing to the exertions of one iron master in Wednesbury in producing a. suitable iron, and to the successful application of machinery to the whole process of manufacture, is in a sufficiently satisfactory state—and, indeed our system has been adopted in its entirety by the Liegois and others—but to the manufacture of twisted gun barrels either as used in trade guns or in high-priced arms. In this branch a very short inspection of the specimens exhibited suffices to convince us, that the barrel forgers of Birmingham and the iron masters of Wednesbury who supply their rod-iron, have a great deal to learn in many respects.

In the first rank for the beauty both of forging and subsequent manipulation come the productions of the Parisian forges; and foremost among them the contribution of M. Leopold Bernard (1337). Most of the specimens which he exhibits are of that particular description of Damascus which was invented by him, and bears his name. “Damas" Bernard designates a method of forging in which a large number of square rods alternately of iron and steel are welded together in such a manner that the cross section of the “bloom " presents the appearance of a chess-board (Fig.610). The mass is then reduced into rods of the requisite size, and a number of them having been first twisted singly like the strands of a rope, are welded side by side into a strap, of which the gun barrel is forged according to the ordinary method employed in making twisted barrels. A noticeable feature in M. Bernard’s contribution is his system of shaping gun barrels by machinery. Specimens are exhibited of the light tubes used for double fowling-pieces in which the rough material is removed and the peculiar curvilinear surface is produced by longitudinal planing, the cutter being guided so as to describe the requisite curve, while the barrel revolves on its axis to present the successive portions of its surface to the tool. The difficulties which this process involves of rendering a thin tube sufficiently rigid to avoid vibration in the cut, have apparently been very successfully combated by M. Bernard. In the British department Messrs. W. & J. Rigby of Dublin exhibit steel rifle-barrels of octagonal section, which are also planed to a curvilinear form by a process somewhat similar, we suppose, to that employed by M. Bernard. In this case, however, the hardness of the material precludes the ordinary method of grinding and filing, and the octagonal form excludes the use of the lathe, so that no doubt can exist as to the value of the improvement in this instance; but we have yet to learn that, as applied to round barrels by M. Bernard, the method presents any advantage over the usual one of removing the rough material by grinding, and finishing with the lathe. In fact we have no doubt that, commercially speaking, the English system is the best. M. A. Bernard (1324) and M. Gastinne Rennette (1335) of Paris also exhibit very beautiful specimens of gun-barrel forging, in the same style of work. Five of the maitres-canoniers of St. Etienne (Loire), fill one case in the French collection with samples of their skill, and the variety and beauty of the figures produced by different methods of disposing the alternate iron and steel is most admirable, and displays great skill in welding. The joint-exhibitors of this collection are (1308) Javelle, Magaud, & Sons, (1309) Ronchard Siauve, (1310) Didier Drevet, (1311) J. Blanchon, and (1312) Javelle Michel. The remarks we have made on the skill of the French gun-barrel welders apply equally to those of Liege; and if the forgers of Paris and St. Etienne have displayed more ingenuity in inventing novel combinations in the disposition of the iron and steel, those of Liege have ever been quick to reproduce them at a lower cost. It is in fact quite impossible to detect the difference between some Bernard barrels manufactured at Liege and the work sent out from the Paris house; and the Belgian barrels are considerably lower in price. This remark applies, however, only to the appearance, and more particularly to the outside appearance, for the Liege barrels are liable to a fault, which is in truth the great defect of their system of welding, namely, the existence of small scales in the here at certain parts under which oxidization commences; and thus after a period of use the under surface rapidly deteriorates. The source of this defect is the “chemise” or lining of common iron which all the continental welders use to economize the expensive Damascus iron, of which alone the finished tube should consist. The intention is, at least in barrels of better quality, that the whole of this lining should be removed in boring; but such is seldom the case in barrels made at Liege, and consequently a thin layer of the “chemise" remains at the breech end, while it is wholly bored out at the muzzle, and there intervenes a part of the bore where it crops out and produces the effect described. This failing has alone prevented the extensive adoption of foreign tubes in English guns. There is no contributor of gun-barrels only in the Belgian collection, but A. de Lezaaek (327), P. J. Malherbe & Company (341), and N. Simonis & Company (343), exhibit a few samples with their guns.

The manufacture of gun barrels as a distinct branch is very inefficiently represented in the British department. The Royal Small Arms Factory at Enfield do indeed very fully illustrate with a well arranged collection of examples the different stages in the production of a military barrel; but the barrel-makers of Birmingham, in whose forges are welded almost all the tubes used in the United Kingdom, have not a single representative who can pretend to dispute the palm with the French makers. Moore & Harris (2570) exhibit specimens of iron and forged barrels in imitation of the French Damascus, but they are not at all equal to the original. In small bore rifle barrels, however, very beautiful specimens are exhibited by the Whitworth Rifle Company (2612) in their rifles, and by W. & J. Rigby, Dublin (2585) in the machined state. These barrels are drilled out of solid bars of a peculiar kind of steel, expressly manufactured for this purpose, and styled homogeneous iron. Those of the Whitworth Rifle Company are turned in a self-acting lathe to the required taper, and are not of curvilinear form externally. Messrs. Rigby employ a different process, the finished barrel having an octagonal section produced by planing longitudinally, the machine being also so arranged as to give a curved surface, and so leave more metal at the breech with equal weight. The other branches which demand attention in considering the manufacture of guns from a general point of view, are the filing, fitting, and tempering the locks and other moving parts of the gun -—such as the trigger, and the movements of the different breech loading systems—the cutting and fitting the stocks, and the final polishing and finishing and ornamenting the different parts. In lock filing it is conceded that the English workmen are unrivalled, and the present Exhibition fully confirms that judgment. It is true that English locks of superior quality are very high in price, but it is precisely in the high-priced locks that their superiority is most marked. The work exhibited by J. Brazier, Wolverhampton (2515), and by James Grainger, Birmingham (2542), is unrivalled for accuracy of fitting, perfection of finish, and for the beautiful temper of the springs and moving parts. There are no locks in the French or Belgian Courts which can be compared to these.

Of breech-loading movements in the filed state there are several exhibitors, E. C. Hodges, London (2548), Brazier (2515), W. C. Scott& Sons (2589), and others. The workmanship of the first named appears to us especially worthy of praise. In this particular department, owing to the priority of invention of the Lefaucheux system, having given them a larger experience, the French and Belgian artisans produce excellent work at a very low price; but it is evident that the progress of the English makers is rapid, and as the most suitable tools are gradually discovered and applied, they must ultimately outstrip those who depend more upon hand work and low wages for sustaining competition.

In the important branch of stocking, &c., combining as it does the most skilful manipulation with the judgment requisite to produce a properly formed and proportioned gun, a comparison is rather in favour of the English workman, and this too in an unexpected manner; for whereas in the merely mechanical part of the work, the close fitting and clean cutting of the wood, he is fully equalled by the French stocker, yet in the appreciation of elegance of form and perfect adaptation of proportion the latter is decidedly inferior. We do not include in this observation those cases where the form and ornamentation of the gun is made a primary object, as in those highly chased and carved guns for which Paris is justly famous; but an examination of any gun exhibited by a first-class English maker with those made in Paris in imitation of our models, will at once demonstrate the truth of our remark. There is another direction in which good progress has been made in this country, and it has proved that Government interference is not always productive of injury to a manufacture. At the Exhibition of 1851 there were exhibited by the United States Government specimens of military arms made by machinery. Since then the Enfield establishment has been expanded into a first-class manufactory in which our Government have, though at an enormous cost, fully demonstrated that machinery is preferable to hand work in producing military guns. The knowledge so gained is bearing fruit. The London Company Armoury exhibit most admirable workmanship in stocking, &c., by machinery. The accuracy and finish of the gun stocks far surpass any hand work, and Messrs. Greenwood & Battley (1610) have in their collection of machines one for letting in the locks of military guns, which is well worthy of inspection. In thus, although tardily, applying machinery to the production of military arms, it is evident that our manufacturers are moving in the right direction, indeed in the only direction in which they have a fair prospect of being enabled to compete successfully in the foreign market with the cheap labour of Belgium. The processes of polishing, case-hardening, browning barrels, and bluing, &c., present no features particularly worthy of remark. The English excel in case-hardening, the object being to preserve the smoothness of the surface, and produce a bright and pleasing colour. In the French work, a sober grey shade is preferred, the bright tints being removed by an application of acid. This uniform colour is more suitable to the elaborate and fanciful designs engraved or chased on the iron work of foreign guns. It is in the production of highly ornamented firearms that the French gunmakers show the most marked superiority over all competitors. The Parisian makers have carried their emulation on this point so far, that they have established a peculiar manufacture which is nowhere else attempted. Their“fusils de luxe" are no longer arms, properly so called, but works of art; the form of a gun being used as a pretext for the most lavish display of the art of the sculptor, engraver, wood-carver, and inlayer in gems and precious metals. When examining one of these chef d’oeuvres of art, we are struck with the ingenuity which has adapted designs, often bizarre and incongruous,'to the uses of a cock, guard, or heel-plate, and are almost inclined to feel regret that the artist was trammeled in his conception by an attempt to conform the outline of his group to the conventional limits of these parts. In enumerating the exhibitors of ornamented guns, we may pass over the British section almost without a word. It is true that the engraving in many cases is very well and tastefully executed, but the designs are conventional for the most part, and no attempt is made to depart from the beaten track. Of those whose work displays the best executed engraving we may mention R. Adams (2506), Gibbs (2539), Lancaster (2557), W. & J. Rigby (2585), and a few others. W. & J. Rigby (2585) exhibit a rifle, the silver furniture of which wrought in original designs, represents the giraffe, elephant, &c. These and some elaborately gilt pistols complete the catalogue of ornamented small arms in the British section.

An adequate notice of the various specimens of artistic firearms in the French court would far exceed the limits of this article, and would indeed come more properly under the department of fine arts. We can but enumerate the most. remarkable—Brun (1303), exquisite pair of pistols in carved box, barrels elaborately chased with a gilt ground; Gerinckx (1325), guns and pistols; Marquis (1326), a double gun ornamented with medallion in stock, and inlaying in excellent taste; L. Perrin (1327), double gun elaborately chased; Lepage Moutier (1339), highly ornamented Lefaucheux double gun, with boar hunt on the lockplates, and pistols; Devisme (1338), guns with chased furniture. A pair of pistols, with designs representing Crusaders and Saracens, the cock wrought into a design representing a Crusader casting a Saracen head foremost against the nipple; battle-piece on the lockplate; knights on horseback, as at a tournament, surround the termination of the handle of stock. These designs are very spirited and well executed. Claudin (1336), a double gun with chased furniture and carved stock ; the butt is perforated by the carving in an involved design representing dragon, serpent, &c. Gastinne Rennette (1335), double gun richly gilt and ornamented; pistols exquisitely carved.

In the Belgian collection some very good specimens of highly ornamented arms are exhibited, but it is evident that the artist has in every case derived his inspiration from French models. Bayet Freres (323) exhibit some very handsome guns, and a Lefaucheux revolver richly carved and inlaid. A. de Lezaack (327), a Flobert carbine, in which the carved ebony stock is worthy of notice ; also, pistols finely chased in the French style. Bernimolin Freres (324). ornamented pistols. Masu Freres (342), Lefaucheux double gun. We have so far only mentioned in detail the contributions of England, France, and Belgium. It is true that highly ornamented firearms are to be found in other collections, in the Turkish and Indian, for instance ; but the style adopted is so well known, and so purely conventional, that it presents no feature particularly noticeable, and we prefer passing to more important matters.

Having now reviewed the various processes connected with the manufacture of firearms, we will proceed to examine the varieties of construction which are so numerously illustrated in the Exhibition; and in order to avoid the confusion which their multiplicity is calculated to produce, we will endeavour to classify the leading ideas involved in the different systems exhibited. With this end in view, we will direct attention, first, to the various methods of depositing the charge in the gun, and of igniting it ; and, secondly, to the modes in which the motive force so obtained is applied, and to the effect produced.

Firstly, then, as to depositing the charge in the barrel. It is obvious that, as a gun barrel may be defined as a tube closed at one end, the simplest construction is that in which, the breech-piece being fixed, the charge is introduced at the muzzle, and is ignited by a stream of flame, produced externally by detonation, and driven through a small aperture into the interior. But it must not be lost sight of that in this method a certain though small escape of gas is inevitable, because the aperture through which the flame is introduced becomes, when the charge is ignited, an aperture through which a portion of it escapes. It is, therefore, erroneous to suppose that escape of gas is an evil inherent to breech-loaders only, the fact being that some muzzle-loaders, the common Enfield rifle for instance, permit a greater loss of power from this source than many breech-loaders.

Although the method of introducing the charge through the muzzle recommends itself by simplicity and strength of construction, still many and important reasons have caused experimentalists from the earliest invention of firearms, to attempt some arrangement which would permit the opposite course, namely, the rapid removal of the breech and introduction of the charge through the opening so made, and its effective closure. Many obstacles combine to render this difficult: the force which we can apply is small; the time necessarily short; the forces operating during the explosion to displace the breech very great; the expansion of the metal by the heat evolved in firing is considerable; the passage of a jet of flame (no matter how minute) through the joint is most destructive, as the effect is that of a blow-pipe flame of great intensity; the hard deposit left after the explosion of the charge impedes and deranges the mechanism, and other causes might be added which combine to render breech~loading a problem of no little difficulty. Two distinct systems have been pursued in modern efforts (and it must be remembered that successful breech-loading does not date back more than twenty years, although experiments extend over centuries), namely, one in which the joint of the breech and barrels is rendered so close by some arrangement of the parts as to prevent the passage of the imprisoned gases, and another in which a separate case or cartridge which contains the charge is used, and by its expansion at the moment of ignition, intercepts effectively the escape of the gas through the joint. The latter method has been most successfully developed by the French; the former by the English, in arms designed for military purposes. As the French or expanding cartridge system is most largely represented in the Exhibition, we will notice it first. This type of breech-loader includes the following :—1. Guns constructed for the use of the Lefaucheux cartridge. 2. Guns with central fire cartridge, which resemble the Lefaucheux cartridge, except in the disposition of the cap. 3. Needle guns. 4. Guns on Flobert’s system, in which there is no cap, but the detonating powder is placed in the rim of a metallic cartridge.

1. THE LEFAUCHEUX SYSTEM.—This system appears by the present Exhibition to be far more generally adopted for sporting arms than any other. It did not come into favour in this country until about 1857, although exhibited in 1851, and invented and largely used in France many years before. Since then, but especially within the last three or four years, it has occupied much of the attention of English makers, and several improvements of construction have been effected. Specimens of the ordinary model of these guns are exhibited by many English makers, viz. :—Baker (2510), Ebrall (2532), Fairman (2533), Gibbs (2539), Holland (2549), Lang (2558), Moore & Harris (2570), Pape (2574), Mortimer & Son (2571), Parsons (2576), Paton (2578), Potter (2579), Reilly (2583), Scott & Sons (2589), Smith (2605), Sylven (2606), Trulock & Harris (2608),Wilkinson & Son (2613), Woodward (2615). In the French and Belgian departments Lefaucheux guns are to be found in the cases of most exhibitors, the chief difference between the English and foreign model being in the shape of the lever, and the substitution of wood for iron in the fore-end of the stock. R. Adams (2506), Westly Richards (2586), Dougall (2529), Bentley & Playfair (2513), are exhibitors of patent guns, which deserve notice in detail.

ADAMS‘ PATENT.—In this gun (Fig. 611) the method of attaching the barrels (Fig. 612) to the breech-piece (Fig. 613) is novel. The latter, in place of extending under the barrel to the full width of the gun at that part, as is usual in Lefaucheux guns, is narrow enough to permit the wood to be continued around it as far forward as the joint on which the barrels turn. At its foremost end is the hinge pin, which receives the hook or half-hinge brazed to the barrels. Further back a square recess is formed, and the barrels carry a strong square stud, which, when the breech is closed, drops into it, and so forms a stop which prevents the recoil from straining the joint. Behind this, and close to the joint of the breech, a steel T-piece is attached to the barrels, which also drops into a recess in the breech-piece. Underneath this, and in the centre of the breech-piece, a lever (Fig. 614) is hung on a cross pin, the longer end of which projects downward, and is bent to lie round the trigger guard. The other end is worked into a claw, which, describing the segment of a circle, engages on the cross of the T-piece, and so prevents the breech ends of the barrels from rising during the explosion.

This arrangement appears to us superior to the ordinary one in which the recoil is taken on the joint-pin. The points of attachment of the barrels and breech-piece being further apart, permit less of that instantaneous displacement which is an evil in Lefaucheux guns, and causes the muzzles to droop when fired. The whole mechanism is light and strong, and by permitting the breech-piece to be reduced in width, and the wood to replace the iron, a form of gun is attained more pleasing to the eye and to the hand, particularly in cold weather, when the contact of iron is undesirable. Before concluding our notice of this gun, we cannot too highly commend the admirable workmanship and finish displayed in its manufacture.

W. RICHARDS' PATENT.—The chief object proposed by inventors of modifications of the Lefaucheux gun, is to render the connection of the barrel and stock more rigid. In the gun now under notice this is sought to be attained by removing the lever to the top of the handle of the gun between the cocks, and making it lock into a bar which extends backward from the breech between the two barrels. The effect is to remove the two points of grasp further apart, and in that respect there is an advantage in diminishing the instantaneous displacement already alluded to; but the position of the lever is inconvenient, and it is necessarily much shorter and less powerful than the ordinary lever, so that what may be gained by its being applied further from the centre is lost in the smaller amount of force which can be brought to bear upon it.

DOUGALL’S PATENT (2529).—In this gun, styled by the inventor the “lockfast,” the barrels are secured to the breech-piece and disengaged therefrom by the action of an eccentric. The end of the hinge-pin on which the barrels turn is made to project at the right side of the gun, and a short lever is attached to it, by means of which the joint-pin can be turned round through a portion of a circle. That part of the joint-pin on which the solid piece attached to the barrels works is made eccentric, so that the revolution of the pin causes the barrels to advance to and recede from the breech-piece. To the face of the breech- piece discs are attached, which, when the barrels are brought home by the eccentric, enter them, and - so prevent the breech end from rising or moving from its place. As additional security a steel stud is placed so as to enter a hole in the solid piece, and aid in preventing any movement of the barrels. In Fig. 615 the breech-piece and solid piece are represented in section. This construction has the merit of great simplicity. The joint pin, with its eccentric and lever, constitute the whole of the moving parts. The attachment of the barrels and breech-piece is strong, and the construction seems capable of being produced at a lower price than even the ordinary Lefaucheux action. On the other hand, the opening and closing of the breech is not so rapidly performed as in the ordinary action or in Adams”, where the act of closing the barrels partially replaces the lever. The lever also appears to us too short and inconveniently placed for the exercise of that degree of force which is sometimes called for, as, for instance, in the case of a slight deposit of fouling on the joints. The patentee estimates the looking power at 1000 lbs. ; but as the thumb, which is alone used in closing the lever, cannot conveniently exercise a pressure of more than 20 lbs, the leverage which multiplies this fifty times must do so at the expense of considerable loss in rapidity of action.

Bentley & Playfair (2513) exhibit a gun marked Erskine’s patent, which seems to possess considerable merit. It is, however, so clearly identical in the main points of construction with Lancaster’s, to be hereafter described, that we cannot see how it can be the subject of a distinct patent. The barrels of this gun advance to and recede from the face of the breech-piece, and interlock with it. The hinge pin is fixed, and the solid piece has a slot which permits it to play on the pin sufficiently to admit the locking and disengaging of the barrels. The traversing action is given by an eccentric disc placed in the breech-piece behind the joint-pin and acting on the solid piece. A lever extending backward over the guard is attached to this eccentric, and gives it the requisite motion.

We have now noticed the principal novelties in Lefaucheux's guns in the British department. In the French no invention of much importance in this direction is shown. Houillier Blanchard (1334) has a gun which somewhat resembles Adams'. The lever has a similar motion, but in place of acting directly, is applied to move a sliding belt which enters a hole in a steel piece attached to the barrels. Thomas (1305) exhibits two single rifles for the Lefaucheux cartridge. In both the barrel is fixed, and so mounted that the cartridge can be introduced into the chamber in a line with the here. In one the breech-piece is made to slide up and down from below through a square recess immediately in the rear of the chamber. It is drawn down to permit the introduction of the cartridge, and pushed up to close the breech by means of a screw of rapid pitch working on the under strap of the gun, and actuated by a lever which also serves as a trigger-guard. In the other the breech-piece is a plate which turns on a pin at the left side of the gun, and drops down across the end of the chamber after the insertion of the cartridge. Caron (1302) exhibits a gun in which the barrel slides in guides, and a fixed breech with a segmental screw is used. The barrel is drawn back after inserting the cartridge, and a quarter revolution interlocks the screw.

In the Belgian department, the Lefaucheux guns are mostly of the ordinary construction. We notice one, a sliding action by Hubar (334), which appears more solid than the ordinary sliding actions known as Bastin’s and Gaye’s [Ghaye], specimens of which are to be found in both the English and Belgian departments.

2. CENTRAL FIRE GUNS, having a cartridge of same materials as the Lefaucheux. Those most worthy of notice are Lancaster’s (2557), Daw (2527), Gastinne Rennette (1335), Bernimolin Freres

(324), and Devisme (1338). Of these, the first two are of French origin, and the latter are evidently but slightly modified forms of them. The cartridges used with these guns differ from the Lefaucheux in having no projecting pin to communicate the blow of the cock to the cap. In Lancaster‘s cartridge no cap is used, but a brass plate is fixed in the bottom of the cartridge, between which and the external copper capsule which covers the base, a small quantity of detonating powder is placed. The cock does not strike this directly, but falls on a steel stud, one end of which is thereby caused to protrude from the breech-piece, and sufficiently indent the copper to cause detonation. 1n the other central fire guns already enumerated, a somewhat different cartridge is used. A cavity is made in the centre of the base, and a cap is introduced from the outside. A small stud or “tige" is so placed in the cartridge, that when the cap is driven inward by the blow of the striker it comes in contact with the priming, and so ignites the charge. This plan is more economical than the first, as the cases may be re-primed; but we fear a slight escape of gas round the cap is inevitable. As to the construction of the guns with which these cartridges are used, Lancaster’s has

the traversing action already described when speaking of Bentley & Playfair’s gun. Gastinne Rennette's and the others have actions like the ordinary Lefaucheux. In Daw’s gun the barrels are held down by a sliding bolt, which enters into a hole in the solid piece on the barrels, and is pressed forward by a spring in such a manner that when the barrels are shut down smartly the bolt springs in and locks them without further manipulation. The absence of the projecting pin, by means of which the exploded cartridge cases are withdrawn from the chambers in Lefaucheux guns, necessitates in

the case of central fire cartridges a peculiar mechanism to effect their withdrawal. This mechanism is very similar in all the plans enumerated. A portion of the edge of the chamber at the joint is removed, and its place supplied by a segment of steel attached to a strong stud, which plays in a hole drilled in the solid iron between the barrels, and is carried as far forward as the hinge pin. On the hinge a steel finger is fastened, the end of which reaches the extremity of the stud, and when the barrels revolve round the hinge, has the effect of thrusting backward the movable portion of the chamber. The cartridge is made with is projecting rim round the base, which is caught by the movable segment, and thus made to project sufficiently to enable the shooters to catch hold of and withdraw it. On a careful examination of these central fire guns, we have no hesitation in giving the preference to Lancaster's. The oblique manner in which the stroke is given to the cap in Daw’s, and the want of rigidity in the manner of confining the barrels, are decided objections.

8. NEEDLE GUNS.—-The needle gun as originally made was not a gun coming under the category of breech-loaders with an expanding cartridge, but there are two systems exhibited by W. & J. Rigby (2585), in both of which that principle is applied. The first we will notice is Needham’s patent, improved by Messrs. Rigby; and before describing the construction of the gun, it is necessary to premise that the cartridge used with it is not a rigid pasteboard tube strengthened with brass, like the Lefaucheux cartridge, but is made of paper, and with the exception of the base, is light and pliable. Two or three discs of pasteboard are compressed together at the bottom to form an elastic cushion, on which the cap is secured by a similar disc having a hole in the centre. A thin zinc capsule on the outside prevents the base from expanding when exposed to damp. This cartridge is much cheaper than the Lefaucheux, and a portable press and a few tools would enable any one to make them for their own use. In the French system the cartridge is with drawn after each shot, consequently it must be strong enough to withstand the explosion and come out entire. In Messrs. Rigby’s gun the base alone is strengthened, and the rest of the tube serves no other purpose than to keep the charge in a portable form. When one shot is fired, the remains of the cartridge case are pushed for ward by the fresh one, and shot away in front of the succeeding charge. We now proceed to describe the gun with which the cartridge is used. Fig. 616 is a side view of the gun, with the breech closed. Fig. 617 is a view of the barrels separated from the stock, one action or breech being represented open and the other closed. The action which contains the lock mechanism consists of two parts which screw into one another. One of these is hung on a cross axis in the rear of the recess. The other is fitted with a finger-piece, which when the breech is closed lies close by the side of the stock. To open the breech the forefinger is applied to this finger-piece, and by means of it the cap is turned round about a third of a revolution. This movement retracts the needle, i.e., cocks the lock, and at the same time withdraws the nose of the action or breech-piece from the barrel sufficiently to permit the whole action to be thrown out into a position at right angles with the bore as in Fig. 617. The cartridge can thus be introduced and the breech-piece replaced. The needle is held back by a catch, which is released by the action of the trigger, and a strong spiral spring then darts it into the rear of the cartridge. On opening the breech to reload, a cam in the action pushes back the needle, and so cocks the lock for the next shot. In the same case with these guns, Messrs. Rigby exhibit another needle gun (Fig. 618), a small rifle for rabbit shooting, which deserves notice for the ingenious manner in which the difficulty of withdrawing the exploded cartridge case is solved. In this gun a rigid pasteboard cartridge is used, strengthened internally by a thin brass capsule. The barrel is hinged to the breech-piece, as in the Lefaucheux gun, but is held down in its place by a peculiar contrivance. In the breech-piece, and opposite the bore of the barrel, a hole is bored and tapped with a four-threaded screw of rapid pitch. A screwed plug fits in this hole, and has a. nose which enters the breech end of the barrel for about 3-8ths of an inch, and so holds it down in its place. Close alongside the gun, and attached to this plug, is a lever, or handle, by means of which the plug can be screwed back and the barrel released. In the foremost end of the plug a recess is turned of the same diameter as the chamber, and the cartridge lies partly in the chamber and partly in this recess, which is slightly undercut, so that when the explosion takes place the base of the cartridge becomes fixed in the plug, and is drawn back by it when it is withdrawn for the purpose of opening the breech. The breech end of the barrel is then raised by pressing down the muzzle, and the cartridge case is bent over and thrown out. This arrangement presents three advantages—first, that the base of the cartridge being inclosed in the recess, no brass capsule is requisite; second, the joint being thrown on the side of the cartridge, escape of gas is prevented; thirdly, one movement of the lever, and the action of ' tilting the barrel, half cooks the cock, opens the breech, and withdraws and ejects the cartridge simultaneously. The traversing motion of the screwed plug answers an excellent purpose in compressing the cartridge endwise, and by this means it is brought into contact with the sides of the chamber, and so prevented from yielding to the explosion, and the bullet is passed firmly into the riding so as to insure its taking the grooves fairly.

4. FLOBERT’S SYSTEM (l306).—The last illustration which we will give of guns in which the cartridge completes the joint is Flobert's patent for small rifles, “pistolets a salon,” &c. The cartridge is of copper, having a rim round the base in which an annular charge of detonating powder is placed. In the pistolets a salon and small rifles the cock forms the support for the rear of the cartridge, and a ridge on it indents the edge and causes ignition. This arrangement is manifestly only suitable to very small charges. A similar cartridge has been recently made use of in the pocket revolvers used in the United States, specimens of which are to be found in the cases of several British exhibitors.

We will now examine some of the most noticeable of the numerous breech-loading systems in which the joint is obtained by the permanent part of the breech, and we at once divide these into two classes, viz., those which have the joint in the rear of the charge, and those in which it is in front. All the guns in the first division are of that class in which the barrel is fixed to the stock and open at the breech. The cartridge is made of prepared thin paper, and the ignition is effected by the flame of an ordinary cap penetrating the paper on the side of the cartridge. The breech is closed behind the cartridge by some arrangement of a plug or stopper, varying in each case, so that our attention need only be directed to the merits of the different methods employed for advancing and securing in its place this plug. In Bailey's patent the barrel is prolonged backwards beyond the chamber, and a steel rod or plunger lies therein which carries on its foremost extremity the plug to close the breech. A bolting lever is connected with the plunger by a pin near the plug, and the upper part of the tubes in the elongation of the barrel is removed to permit the introduction of the cartridge and the action of the bolting lever, which when closed lies along the handle of the stock. To load the gun the lever is raised, which action releases the plunger, and enables it to be drawn backward. The cartridge is then introduced, and the plug replaced. Cooper & Goodman’s gun has also an arrangement of compound leverage, which withdraws or advances a plug in an elongation of the barrel. The cartridge is inserted at the top. King & Philips’ plan is an application of the sectional screw as the means of locking the plug, which it is difficult to describe without drawings. ln Webley’s the plug is attached to a handle that lies along the top of the stock, and by which the plug is directly pulled out and pushed home. It is locked by a broad key-piece, which works through a slot cut in the plunger and the sides of the barrel. Calisher and Terry’s—The construction of this rifle is strong and simple. The barrel as before is continued backward beyond the chamber. A portion at the side is removed to admit the cartridge, which is thrust forward by a steel plunger. This plunger carries on its foremost end a conical plug which fits into a conical recess at the rear of the chamber. 011 the other end it has lug pieces, and a lever or handle is jointed to it. It is first thrust forward, then by means of the lever turned round through 90°. This action brings the lug pieces into helical recesses, which cause the conical plug to be strongly pressed into its bed. The handle then folds down, and prevents the plunger becoming unlocked. As before a cartridge of penetrable paper with a felt wad in the rear is used.

Reeves (2582) exhibits two rifles. One is like Terry’s patent last described, very slightly modified. The other is in every respect similar to Thomas’ of Paris Lefaucheux rifle, which we noticed under the head of guns having an expanding cartridge. The manner in which the breech is pushed up from below and drawn down to admit the charge is the same, but Mr. Reeves proposes to use not a Lefaucheux cartridge, but a common cap and the greased wad arrangement. Westley Richards', Restell’s, and Parson’s rifles have some resemblance. The former has an excellent reputation, and has been partially adopted by our government. The cartridge used is as before of thin paper, with a wad of felt soaked in tallow. It has a joint to enable it to be introduced into the bore, as the trap at the rear of the barrel which receives it is not long enough to permit its entrance otherwise. This trap is a rectangular box, open at the top, and screwed to the breech. The hero of the barrel is continued into it. On the barrel at the breech a lever is hinged, which lies along the top of the handle and covers the box. Along its under surface a piece of iron slides in a dovetail, and carries on one end a brass button. When the cartridge has been pushed into the chamber this lever is brought down, and the sliding piece of iron enters the box. One end abuts on the solid end of the recess, and by means of an inclined plane formed on it causes the sliding piece to move forward, and drives the brass button into the box behind the cartridge.

Parson‘s rifle is very similar in appearance to Westley Richards’, but the action is different. The brass button is not used, and the plug which closes the breech is spherical and enters an enlargement of the bore behind the chamber. A short tube of brass is fitted in this cylindrical enlargement, and is capable of sliding in it. The spherical head of the plug touches the brass tube, and the sheet of the explosion is to drive it backward, and force it against the sphere in such a manner as to cut off escape. This ingenious arrangement appears open to the objection that the brass tube which, from its position, cannot be examined or cleaned would probably in service become fast in its place, and cease to provide the requisite compensation.

Restell’s patent, which is, we believe, of somewhat earlier date than either of the others, resembles \Westley Richards' in the manner of introducing the charge, but has a different arrangement for locking the plug. The lever lies along the side of the gun, and puts in motion a cam hung on the same cross axis. The cam, which is an eccentric plate, plays in a slot in the rear of the plug, and having pushed it forward into its bed drops down into the slot, and, abutting against the end of it, locks the plug in that position.

LANCASTER’S PATENT.-——This gun differs from all the former in the method of preventing escape of gas, and in the cartridge. The idea which it seeks to carry out is not new, but has not hitherto been successfully applied. It consists in using a cartridge with the bullet behind the powder. For the first shot a bullet only is inserted, followed by a cartridge. The bullet in the cartridge rests on the plunger, which closes the breech, and when the charge is ignited is driven back upon it so as to become expanded, and prevent any escape. The plunger is in two parts, an outer tube with lug pieces to lock it in its place, and a rammer sliding in it in such a manner that after each shot it can be used to push the remaining bullet forward in the chamber, and so make room for the introduction of the succeeding charge. The ignition is effected by a common cap, the nipple being placed under the barrel; but Mr. Lancaster does not confine himself to this arrangement. The improvement which he claims is designed to obviate the difficulty which was fatal to former attempts to carry this idea oi a bullet in the rear of the charge into practice. The hindmost bullet is liable to become so fast in its place, as to require more force to impel it forward than can be conveniently applied. In the present gun a slight enlargement is made in the chamber behind the bullet, and an elastic wad of felt or other materials is attached to its base. The effect, we presume, is to reduce the expansion of the bullet to manageable proportions, and at the same time to cut any possible escape, while the wad is also useful, lubricating and cleaning the chamber and barrel. We have so far only concerned ourselves with the method of introducing the charge and closing the breech. We will revert again to these rifles when we have their accuracy of shooting under consideration.

It may be remarked that all the breech-loaders hitherto noticed require a special cartridge. In the first class the cartridge carries its own ignition. In the second a cap is used, and the special cartridge is of penetrable paper, with an attached wadding. We now come to the only kind of breech-loader which is independent of a cartridge, and is capable of being used without one. In this class the joint is placed in front of the charge. In fact the charge is contained in a chamber which is then brought by the mechanism into a line with the barrel, and forming with it a continuous tube. The examples are Gilby’s (2507), Leech (2516), McKenzie &Wentworth (2549), Mont Storm (2569), Murcott & Hanson (2572), Rigby (2585), Wylie (2617), and the Norwegian rifle.

Gilby's patent has been some time before the public, being one of the very few breech-loaders exhibited by English makers at the Exposition Universelle at Paris in 1855. The chamber, which resembles in every respect the breech-end of an ordinary barrel, is mounted on a cross pin at its hindmost end, and when released (by pressing a stud on the side of the gun) is thrown up by a spring underneath into a position at an angle of about 60° with the barrel. In this position, it is loaded with loose powder and ball. The loading is completed by pressing down the chamber until it is caught by a spring catch, which enters a slot in a piece attached to the chamber underneath. Three of the specimens exhibited have a self-capping arrangement added. The want of any check to the escape of gas through the joint would be fatal to the durability of this gun.

Leech‘s patent, exhibited by the Breech-loading Gun Company is open to the same objection, although some attempt is made to prevent the destructive effects of the flash by inserting a ring of platina at the place where it impinges. The chamber is mounted on an axis underneath and parallel to the barrel, and is moved out of line with it to the right for the purpose of loading. McKenzie & Wentworth's patent is exhibited by Holland (2549). In this gun the barrel is screwed into a tubular breech-piece, the bore of which is about equal to the external diameter of the barrel. This breech piece is open at the top, and extends back about six inches. In it the chamber lies (carrying the nipple, &c.), and is so mounted by an ingenious screw arrangement, actuated by a short lever which lies on the top of the handle, that the movement of this lever draws back the chamber, releases its foremost end from a recess in the barrel, and turns it up to receive the charge, and the reverse action replaces it and pushes it into the recess. This traversing motion and the conical joint is designed to prevent escape of gas, but no conical joint is entirely effective for that purpose. Mont Storm's patent attracts attention from the inventor’s proposal to convert all our military rifles into breech-loaders by means of it. The barrel is, as in the last case, screwed into a breech-piece with a recess in which the chamber, representing the breech and about two inches of the barrel, lies. The chamber is attached to the barrel by a hinge joint on top, the pin of which is immediately over the juncture of the chamber and the barrel. When the cock is raised the finger is applied to a button on the side of the chamber, and it is lifted from its bed and turned over on the top of the barrel, with the opening towards the breech. In this position the charge is inserted and the chamber or movable breech end is replaced. When the cock falls, it causes a bolt to protrude through the rear of the recess in which the chamber lies, and to enter a corresponding hole in the chamber. In this manner the latter is held down in its place, and a safeguard is provided against the cock falling when it is not quite home. The provision against the escape of gas is made by a movable nose-piece to the chamber, which enters an enlargement of the bore in the rear of the barrel. The nose-piece is a thin steel tube, slightly conical, which is fitted into the chamber, and projects sufficiently beyond it to enter and fill the enlargement of the barrel. When the charge is ignited it is urged forward by the explosion, and so kept strongly pressed against the barrel. The efficiency of this arrangement evidently depends on the nose-piece being free to slide in the chamber.

W. & J. Rigby exhibit a carbine on Rigby & Needham’s patent, in which a much more efficient joint is obtained. The barrel is, as before, screwed into a tubular breech-piece, open on the top and wide enough to receive a chamber as strong as the barrel, in fact supplying the place of the breech and first two inches of the barrel. This chamber has a lever or handle placed under the nipple, and lying close to the side of the stock, by which it can be turned round in its bed about one-third of a revolution, and then lifted up. Behind, it is attached to a piece of iron by a screw of rapid pitch, and this latter piece is hung on a cross axis. When the chamber is turned in its bed the screw draws the foremost end out of a recess in the rear of the barrel, and it can be lifted up to a position at right angles with the box to receive the cartridge or loose charge. The recess in the barrel is cylindrical, and there is a corresponding cylindrical projection on the chamber. The movement of the joint in firing causes this projection to slide in the recess without separating the surface or permitting escape, against which the expansion of the chamber also provides. In this gun the chamber is the same bore as the barrel, and the rifling is continued into it, so that the ball expands in the rifling as in a muzzle-loader.

The last chamber breech~loader which we shall notice is Wylie's. The whole arrangement of this gun is original, and its description consequently difficult. The chamber slides in a hollow breech piece, and is locked in its place by a sectional screw on its surface. A handle projecting from it enables the shooter to turn it round a quarter of a turn (which disengages the sectional screw), draw it back, and finally tilt up the end to receive the charge. The same movement cooks the lock, which is placed underneath, and brings the nipple into a position to receive a fresh cap from the self-capping apparatus placed in the stock. The reverse movement replaces and locks the chamber, and the loading is complete. The chamber has a long nose-piece which enters a slightly conical recess in the barrel, and so prevents escape of gas. The bullet is permitted to project from the chamber, and so enters the barrel, and lies in the rifled portion. The inventor claims for his gun the advantage of being automatic, and at the same time capable of being cocked and capped, &c., in the usual way, or used as a muzzle loader if required.

Having now passed in review the most remarkable constructions in the department of breech-loading firearms, we will direct our attention to rifles for military purposes and for target practice. In 1852 our Government first adopted into the service the French invention of expanding bullets for rifles. In the following year the present Enfield rifle was designed, and in a few years totally superseded smooth bores in all branches of the service. The sudden demand so created being inadequately supplied from the ordinary sources, it was resolved to attempt on a large scale what had already been effected in America on a smaller one, namely, the application of machinery to the manufacture of these rifles in so complete a manner that in any number of guns all the parts of the gun should be interchangeable.

The Royal Small Arms Factory (2603) contribute a most complete and interesting series of specimens of the various parts of the rifle in its progressive stages of manufacture. The London Armoury Company (2561), who manufacture on the same system, also exhibit very beautiful examples of what can be done by the special adaptation of machinery to particular objects. The Birmingham Military Arms Trade (2513) have a very fine collection of arms of various models. The application of machinery is only partial in these, but is, we believe, extending, and has made considerable progress during the last two years.

In the French department F. Escoffeir, of St. Etienne (1317), exhibits specimens of military arms, among which are the long and short Enfield, closely copied from the English model. The Belgian contractors are represented by Dandoy (326), and Malherbe & Company (341). In their cases may be seen the various models of military arms used by many of the European states, and conspicuous among them the Enfield rifle.

We have remarked before on the importance of obtaining the assistance of machinery in the manufacture of military arms, and we note with pleasure in the machinery court in the contribution of Messrs. Greenwood & Batley (1610) two machines, one for rifling the barrels of Enfield pattern guns, and the other for letting the looks into the wood, which have been made for the Birmingham trade. The particular merit of the rifling machine (Fig. 618%) is in the arrangement by which the length of the stroke is varied so as to economize time, by only permitting the cutter to return over so much of the barrel as is to be cut in the succeeding stroke. The feed is also self-acting, and by an ingenious arrangement the cutter is withdrawn into its sheath on the return stroke, so as to keep it clear of the work.

The general adoption of the Enfield rifle in our army, and the importance which is given to accurate shooting at long ranges, have caused many experimentalists to attempt the further improvement of that model. There are several exhibitors of long-range rifles in the English department, all of which are designed on the principle of a reduced bore and a more elongated form of projectile. With the exception of the rifle which takes its name from the late General Jacob, all these are '451 bore, and throw a bullet of 530 grains. Specimens of General Jacob’s military rifle are exhibited by Swinburn & Sons (2513), G. H. Daw (25-7), and others. The bullet carries a percussion shell, is about 1/2 inch in diameter, and 1 1/2 inches long. Its range and accuracy are considerable, but in both it has been surpassed by rifles of smaller calibre constructed on the system for which we are mainly indebted to the series of experiments carried out some years since at the instance and at the expense of the Government by Mr. Whitworth of Manchester.

Among the exhibitors in this section are the Whitworth Rifle Company (2612), the London Armoury Company (2561), C. W. Lancaster (2557), W. & J. Rigby (2585), R. Adams (2506), F. T. Baker (2510), It. Jackson (2550). In all these the bore is nearly the same, and the general principles of length of bullet, degree of spiral, &c., are very similar. The method of rifling, and the section of the bore constitute the chief difference. In Whitworth's rifles the section is a hexagon with rounded angles, the grooves are of equal depth, and the spiral equable from breech to muzzle. The bullet is hexagonal, to fit the rifling, and is of lead slightly alloyed to render it harder. For military purposes, however, when quick loading is requisite, a leaden expanding bullet is used, but the patentee prefers the fitted bullet on the score of superior accuracy.

The rifles exhibited by the Whitworth Rifle Company are very well made and finished. The sights are extremely accurate, but appear rather delicate and liable to injury. We have before drawn attention to the superior quality of the barrels, which are drilled out of solid bars of mild steel. The hexagonal cartridges for these rifles exemplify the care and accuracy with which every part of the system is carried out. The powder in each cartridge is separately weighed, and both it and the bullet are guaranteed to a fraction of a grain.

Among the collection of rifled ordnance is exhibited Whitworth’s Patent Machine Rest, which we engrave, as it is an important auxiliary to experiments; with it the mean deviation of the rifle is tested, which gives a certain measure of the accuracy of the gun. The angle

Last edited by Steve Nash; 11/18/19 11:45 PM.

|

|

|

|

|

Joined: Feb 2016

Posts: 3,158 Likes: 319

Sidelock

|

OP

Sidelock

Joined: Feb 2016

Posts: 3,158 Likes: 319 |

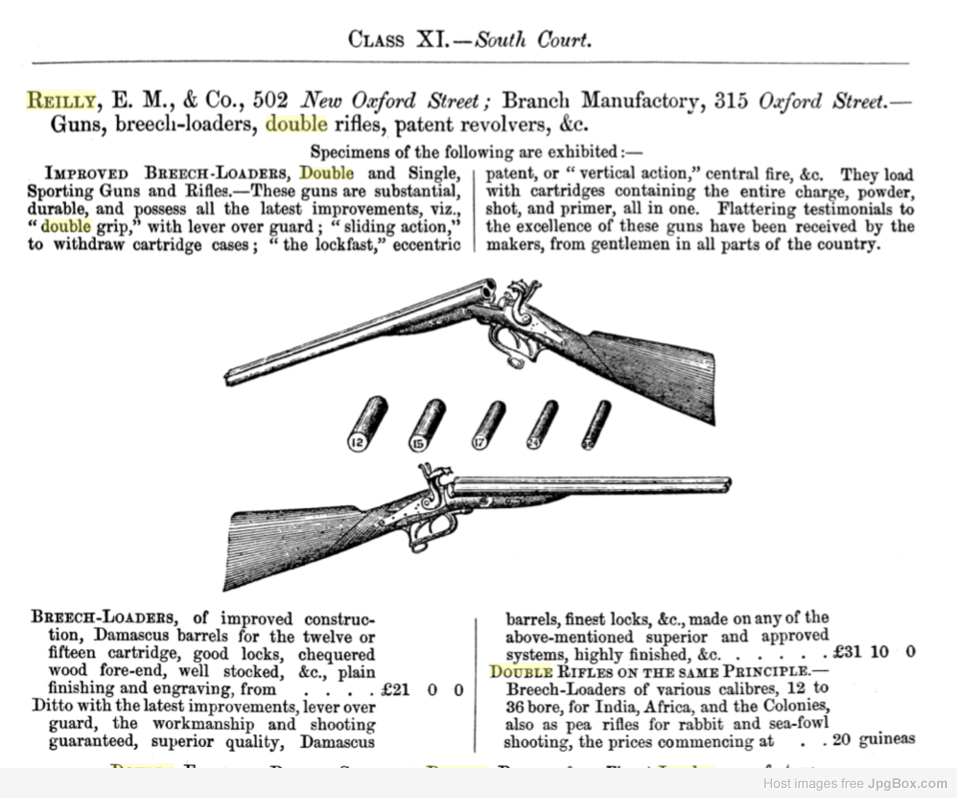

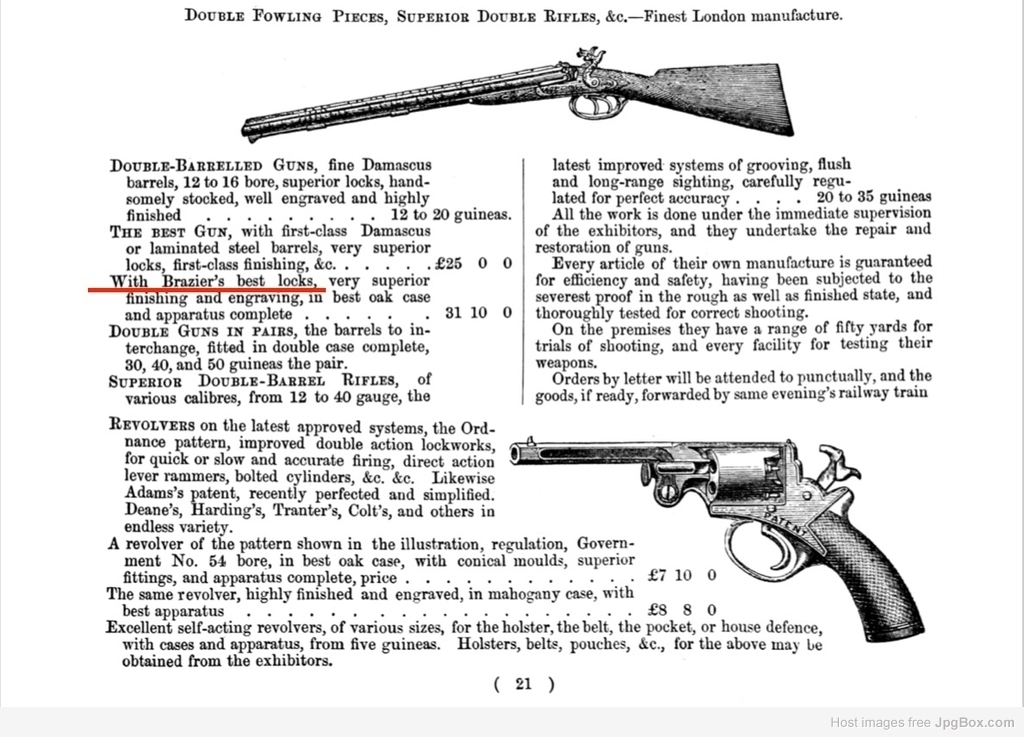

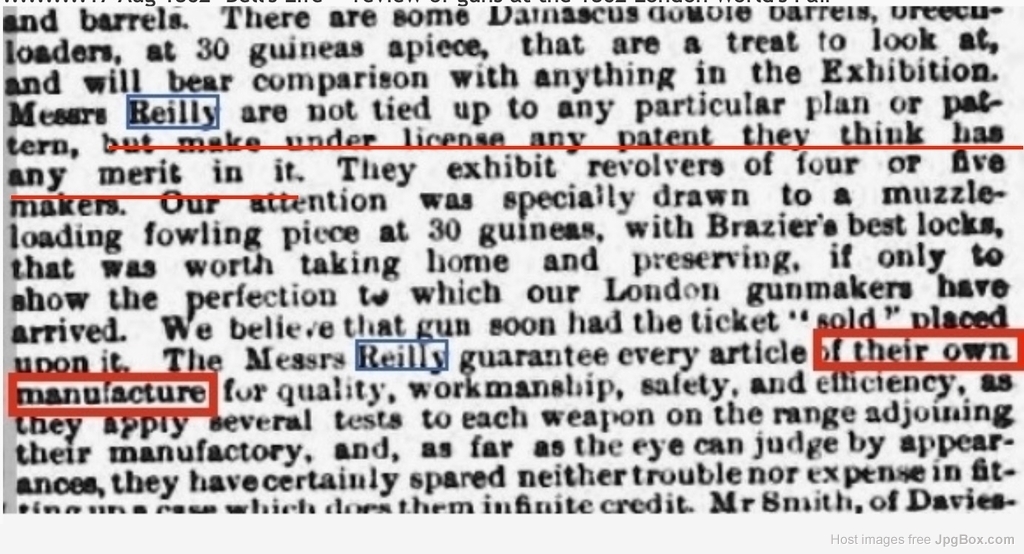

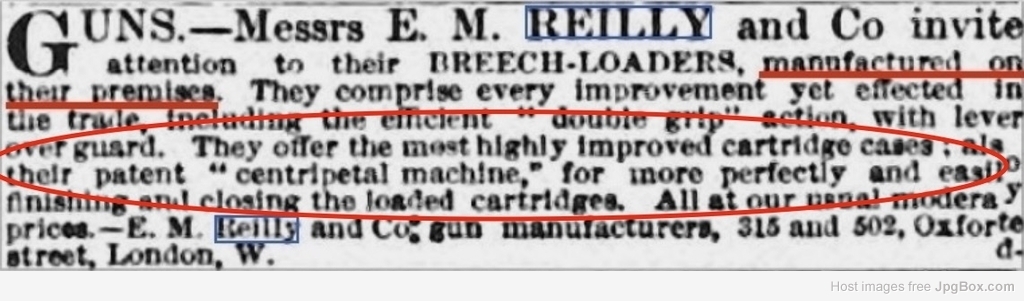

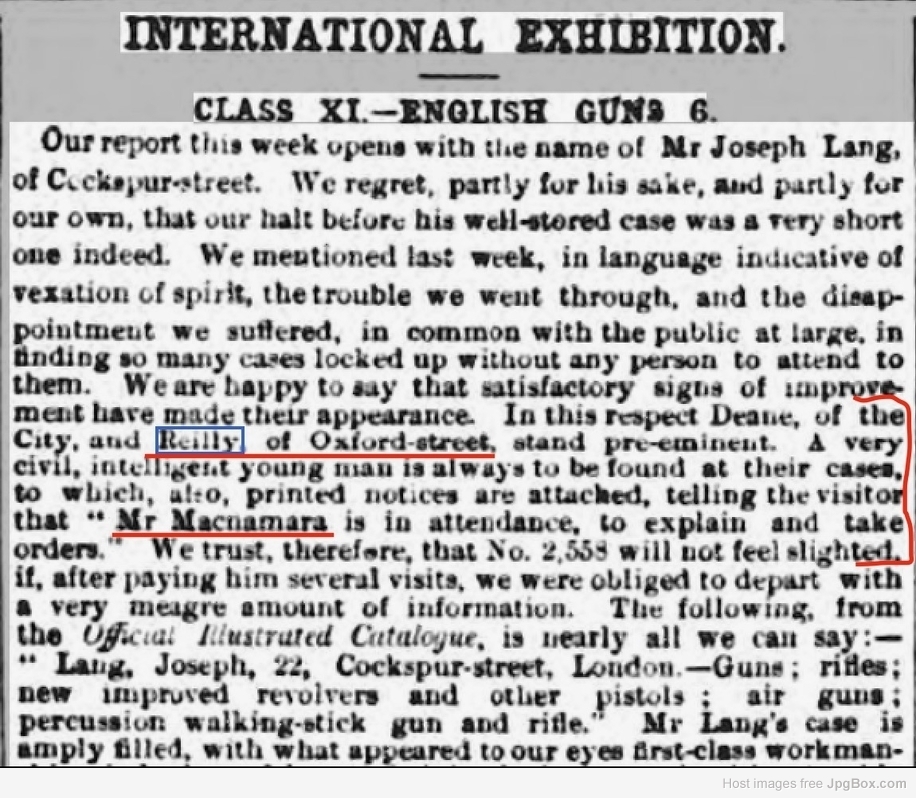

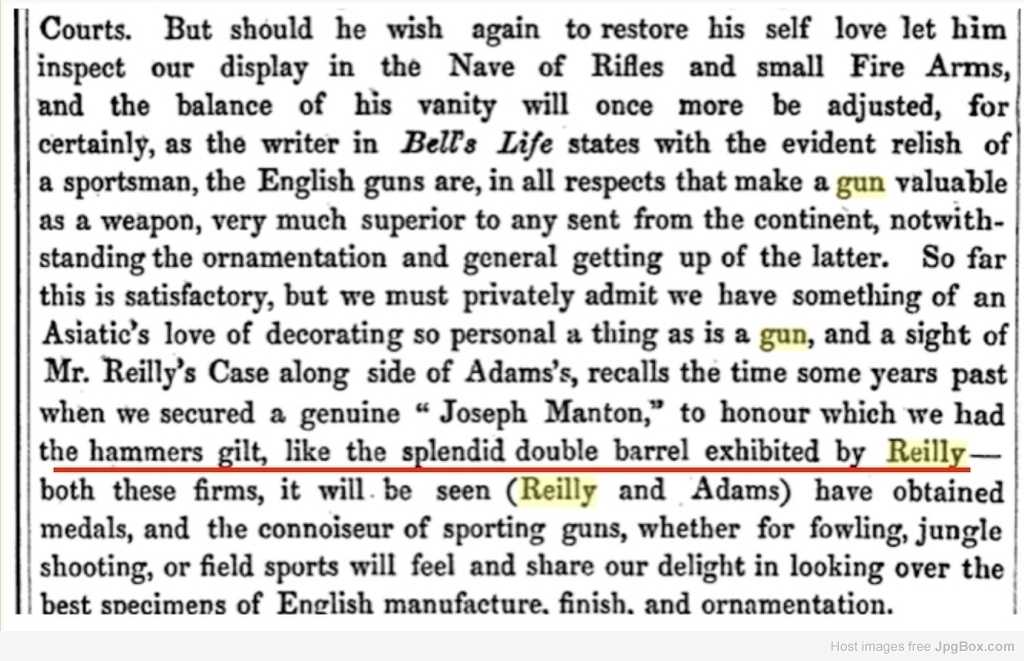

Many thanks Steve...leave it where it is. The "World's Fair" Expositions of 1851 (Crystal Palace, London), 1855 Paris Universelle, 1862 London, and 1867 Paris are particularly important because everybody who was anybody was there. Reilly, after the 1855 Paris Universelle, in particular targeted these expositions and the medals won were major advertisements. 1855 (where all his goods where sold and many orders were booked - no further information for the moment) and 1867, where he outright won the gold medal, where his triumphs. Here is Reilly's 1862 exhibit - Note that in 1862, you could order a Best Reilly Muzzleloader with Brazier locks for an extra 6Ł (Steve Nash mentioned above that Joseph Brazier of Wolverhampton provided actions to gun finishers based on the Lang design - the below Reilly ad, however, in 1862 was for locks for muzzleloaders - for which he was best known): https://books.google.com/books?id=BJfHM1...ent&f=false  1862 was a disappointment - he meticulously prepared for the Fair but only got a sort of "participation medal." But three things for this Reilly line came out of the exposition: 1) The advertisements in the exposition catalog and the newspaper interviews and publicity before the exposition definitively state he was manufacturing guns at 502 and 315 Oxford Street, allegedly making every piece himself, and was making the guns that he perceived to be salable under patent license. ..........17 Aug 1862 "Bell's Life" - review of guns at the 1862 London World's Fair  ..........1862 Exposition catalogue  ..........1861 - note the reference to the John Baker cartridge sealing patent in a mid-1861 advertisement.....and note the reference to an underlever "double-grip" system - which seems to indicate Reilly was building Jones U-L at that date:  2) The Identity of at least one of his employees, a young "Mr. McNamara.  3) The description of a gold washed muzzleloader that at least one writer in September 1862 waxed poetic about and which may still exist - SN 12532 (dated on my chart as mid-1862; it is used as a "sanity check" for the accuracy of the chart) https://books.google.com/books?id=mvkHAA...gun&f=false http://www.invaluable.com/auction-lot/e.m.-reilly,-london-a-gilded-and-cased-12-bore-pe-545-c-cbe4d2e8d5 E.M. REILLY, LONDON A GILDED AND CASED 12-BORE PERCUSSION SPORTING-GUN FOR PRESENTATION, serial no. 12532,

circa 1855 ( [color:#FF0000]wrong[/color]) and for the Indian market, with re-gilded fully fluted 32in. barrels, the top-rib signed 'REILLY 502 NEW OXFORD STREET LONDON' and surrounded by a field of engraved acanthus scrolls, further panels of acanthus scroll-work forwards of the fore-end and at breech, scroll engraved re-gilded top-tang, re-gilded fully acanthus scroll engraved bar action locks signed 'REILLY LONDON', en-suite hammers, re-finished highly figured chequered walnut half-stock (cracked at hand), re-gilded furniture including heel-plate with engraved spur, fully scroll engraved trigger-guard bow and tang, engraved barrel wedge escutcheons and ramrod throat, fluted ramrod pipes and ebony ramrod; TOGETHER WITH its manufacturers walnut presentation case bound on the exterior with pierced and engraved brass mounts with a vacant central shield, the interior lined in embossed red velvet (thinning in places) with gilt borders and details, the inner lid signed in gilt block letters 'E.M. REILLY 502 NEW OXFORD STREET LONDON', the tray compartmented in the English manner and containing the original red morocco leather shot flask with gilt embossed decoration, the possibly original but period powder flask signed 'JAMES DIXON & SONS, SHEFFIELD' and an 'E.M. REILLY' brass wad-punch  But I will say this and I think I can back it up. 1857-1870 was the Hay-Day of Reilly. There is a cockiness about their advertising, their sending zingers at the "establishment" such as Purdey. They for a short time tried to advertise themselves as gun-makers to the Royal family in 1862. They won outright the gold medal in 1867 in Paris, opened a Paris shop; they became gun-maker to Napoleon III, strutted into America. They had great hopes of winning the 1865 breech loading trials with the Green Bros breech loader and 1869 trials with the Reilly-Comblain. All this is documented above.

Last edited by Argo44; 12/04/19 06:48 PM.

Baluch are not Brahui, Brahui are Baluch

|

|

|

|

|

Joined: Jul 2014

Posts: 427 Likes: 76

Sidelock

|

Sidelock

Joined: Jul 2014

Posts: 427 Likes: 76 |

As you demonstrate so well, contemporary accounts, records, advertisements, case labels, and publications are the best sources for unravelling the story of gun development in the 1850s and 1860s. But I have to say, what really made my week, Gene, was the reference to the Blanch scrapbook items, and the 1855 bill of sale for a Beringer gun. It suggests with real evidence that London makers sought foreign guns to study and copy. Research on the competition makes sense! It also helps explain how and when foreign innovations started turning up in British guns, and the reverse is probably true as well. While the French made great advances with percussion ignition, it looks like much was based on getting their hands on a Forsyth ‘scent-bottle’ gun. The quintessential British lever-over-guard might have been inspired by Blanch getting his hands on that 1855 Beringer... or by another maker with another gun. In any case, it shows how there might have been a cross-pollination of ideas. The fairs and exhibitions would have been another source of professional curiosity, and comparison.

|

|

|

|

|

Joined: Aug 2007

Posts: 10,784 Likes: 185

Sidelock

|

Sidelock

Joined: Aug 2007

Posts: 10,784 Likes: 185 |

I think the >>cross-pollination of ideas<< was achieved by the walkabout each mechanic made. This was the conduit for the transfer of technology & more than likely how pattern welded tubes made their central migration, along with spoils of war. We know that many of the Continental mechanics passed thru the Little British Isles, but I haven't seen any info for vice - versa.

Cheers,

Raimey

rse

|

|

|

|

|

Joined: Feb 2016

Posts: 3,158 Likes: 319

Sidelock

|

OP

Sidelock

Joined: Feb 2016

Posts: 3,158 Likes: 319 |

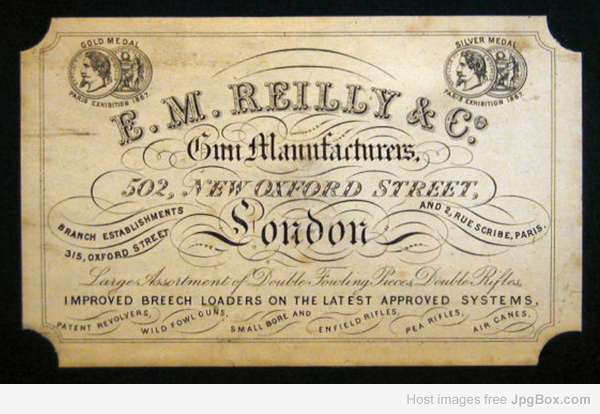

I'd like to make a record of this: In the 11 Dec 2019 Gavin Gardner catalog, Lot 144 - Parts to build a 4-bore double barrel Hammer gun. E.M. Reilly action, with underlever, fore-end, iron trigger plate, hammers, etc. Here is what Gavin sent me about the action: As you can see from the hi res image, it is just a kit of unfinished parts, in the white. It has come from someone in the trade who refers to it as the “Reilly” action and insisted that I refer to is as such…. but of course it impossible to prove that this unfinished action is originally from the Reilly works. There are no marks or identifying numbers I am afraid. So, at least one person in the "Trade" believes Reilly made the action (or had bought it intending to finish it himself). Interesting. Has the action backstrap already been engraved? The same consigner has four or five other 4 bore actions in the auction, each one labeled with a gun maker's name....there is more to this story. I am very curious about the age of the action. Obviously a center-fire hammer-gun with deep percussion fences....but other than that? Here are three Reilly big bore percussion fences - nothing like the one in the parts bin above (percussion fences on guns that were originally pinfire face away from the center fire firing pins): 1) 15964 - 1869 4 bore (orig pinfire); . . . . . . . 2) 15565 - George L's 4 bore (orig pinfire) (1869); . . . . . . . . . . 3) 18860 - 4 bore (1874)  Is it my imagination or were there two halves to each hammer (meaning that they must have been welded together for the finished product). Double interesting. I could see a manufacturing efficiency reason for this. Or are there just extra hammers in the box? The label in the plastic bag looks to be a reproduction (no scolloped corners) of the generic label with the Paris medals...Post February 1868. The small scroll items at the bottom of the label changed as the years passed (certainly after 1885) (and, though I don't have as many examples to definitively state this, "502" continued to be used until circa 1885 when it was changed to "16")....this one looks still to have "Enfield Rifles" on it (the reproduction labels do - if you're looking for a Reilly reproduction label for an 1880's-90's Reilly gun these would not be authentic). Post Feb 1868 original label:

Last edited by Argo44; 12/05/19 12:37 AM.

Baluch are not Brahui, Brahui are Baluch

|

|

|

|

|

Joined: Dec 2001

Posts: 6,993 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,993 Likes: 402 |

Looks like some vintage forgings along with some modern cast parts. The action is pretty far along but still tons to do on that one.

|

|

|

|

|